4529749

FOLLOWERS ON SOCIAL

2234573446

VIDEO VIEWS

4761529749

IMPRESSIONS

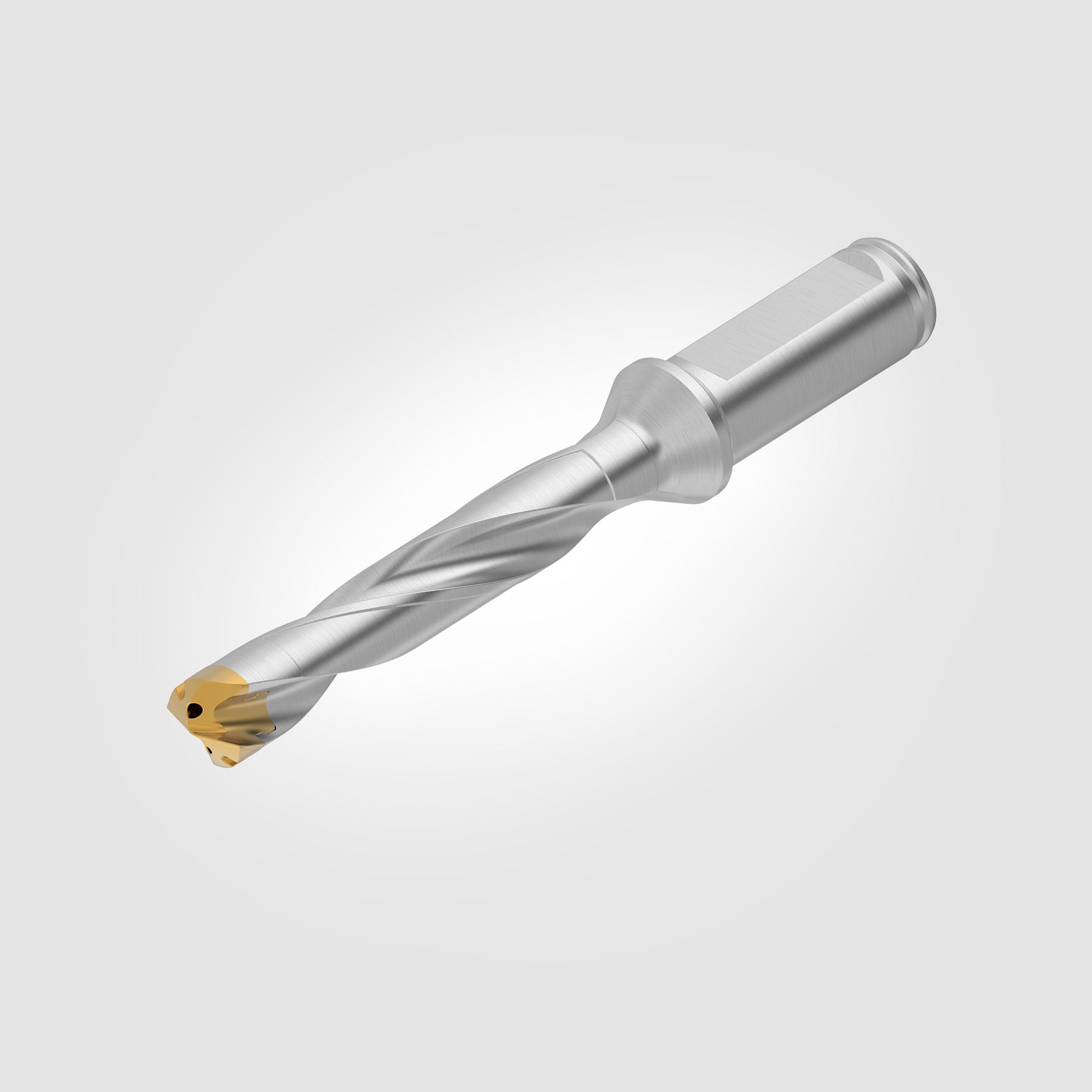

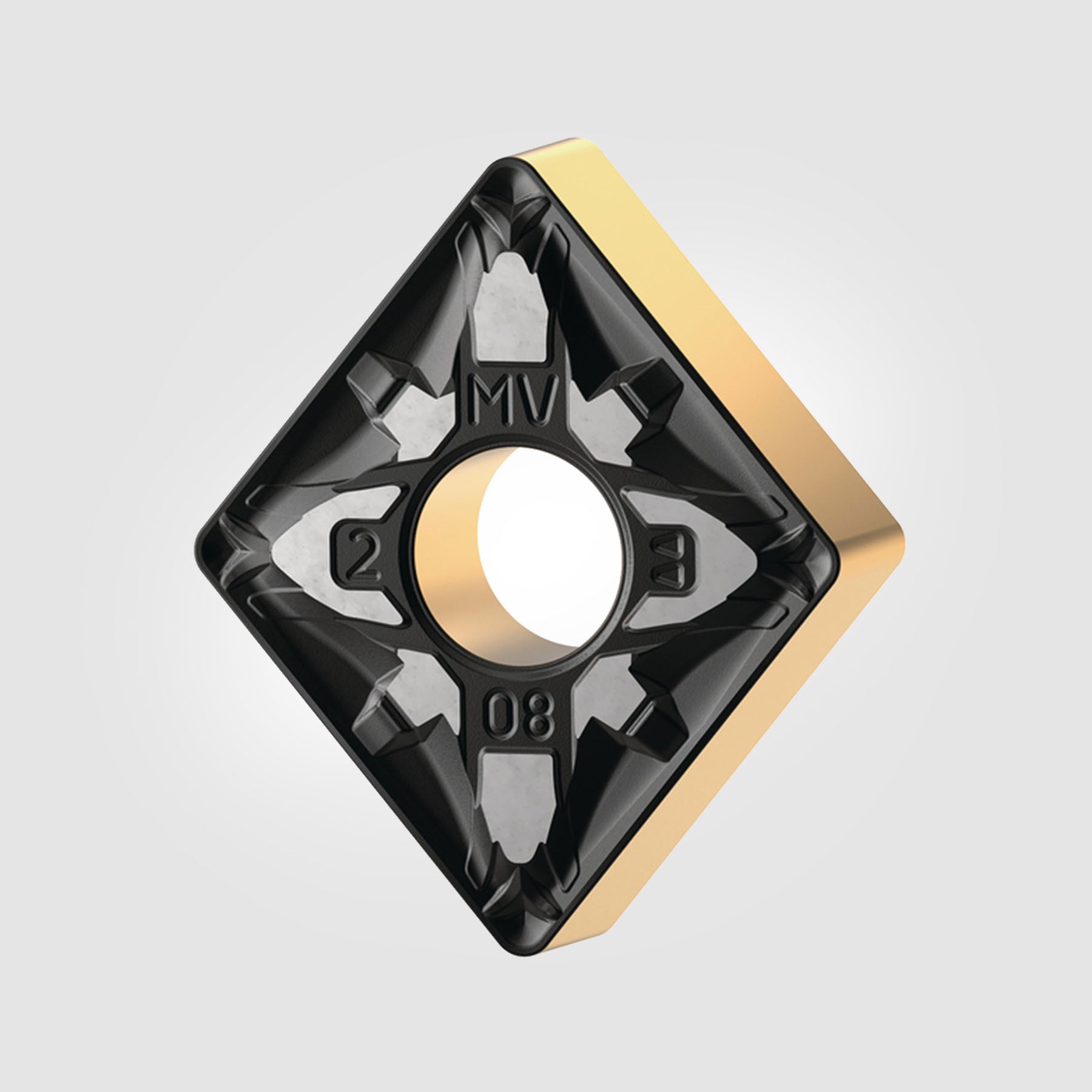

Build Your CNC Shop

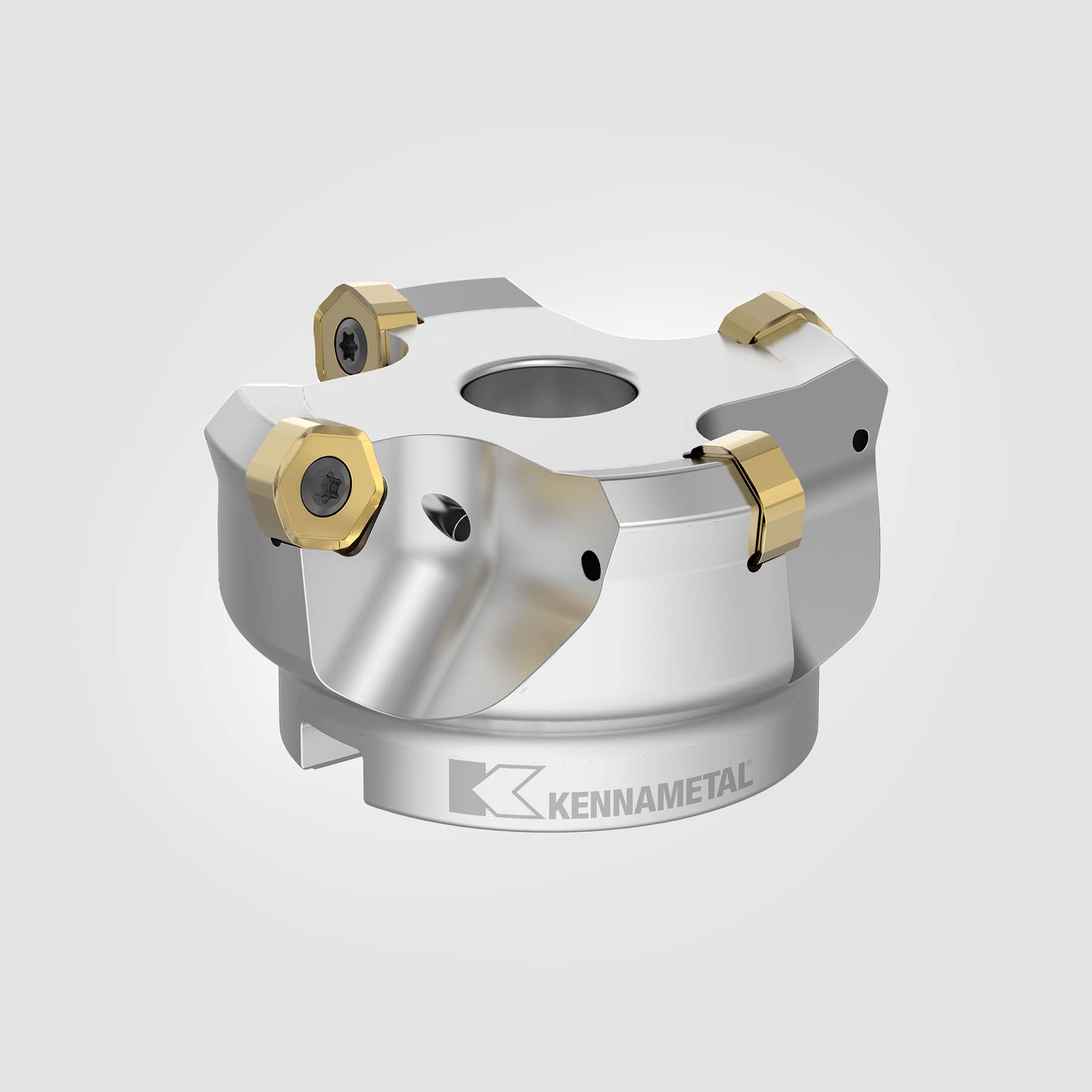

TITAN-approved tooling, workholding, inspection tooling, and more!

OUR PARTNERS HELP FUND FREE EDUCATION FOR ALL

HELP CHANGE THE WORLD!

PARTNER WITH USQuestions? We're here to help.

Check out the most common questions our community and customers have asked. Still have questions? Contact our customer support.

What is TITANS of CNC?

TITANS of CNC is a suite of manufacturing education platforms, a social media influencer brand, and an online store for tooling, machine tools, and accessories. Founded by Titan Gilroy, an Expert in Advanced Manufacturing, we create advanced manufacturing curriculum for all generations of machinists and programmers.

I want to learn CAD/CAM/CNC, where do I begin?

We created the Building Blocks Mill and TITAN Rocket Lathe series so that they would be easy to follow and understand for everyone from true beginners to those who have already been in the industry for awhile and just want to pick up some new skills. Start by clicking one of the links above and follow the directions. You can also review the TITANS of CNC Instruction Manual for more detailed information.

How can I help support the mission of TITANS of CNC?

Two simple ways to help us.

1. Follow our social accounts and like, subscribe, comment, etc. this helps the algorithms show our content to more people globally, and that is one great way to help us spread the message about Advanced Manufacturing.

2. All of the proceeds from our store go 100% to funding additional Advanced Manufacturing curriculum and videos. So simply purchase products from our store. Not only do we have very competitive pricing on all sorts of tooling, measurement tools, and other shop needs... We are now distributors for a variety of machine tools and higher ticket items. We've even teamed up with a financing partner to help you build your shops' credit and buy those big dollar items that we may not currently carry on our store.

What are the benefits of the TITANS of CNC: Academy Curriculum?

The TITANS of CNC: Academy Curriculum is endorsed by thousands of educators, industry professionals, and top manufacturing companies. Kennametal, HELLER, DN Solutions, Mastercam, United Grinding, Tornos, Blaser Swisslube, Blue Origin, and many other top industry names all back the Academy and its mission to train the NOW Generation of Machinists. Completing our curriculum and earning your CNC EXPERT certifications proves your comprehension of fundamental design, programming, manufacturing techniques, and increases your ability to solve problems for current and future employers.

Still have questions?

You can contact us through our contact page! We'll be happy to assist you.