3D Printer in production. Ships later this year.

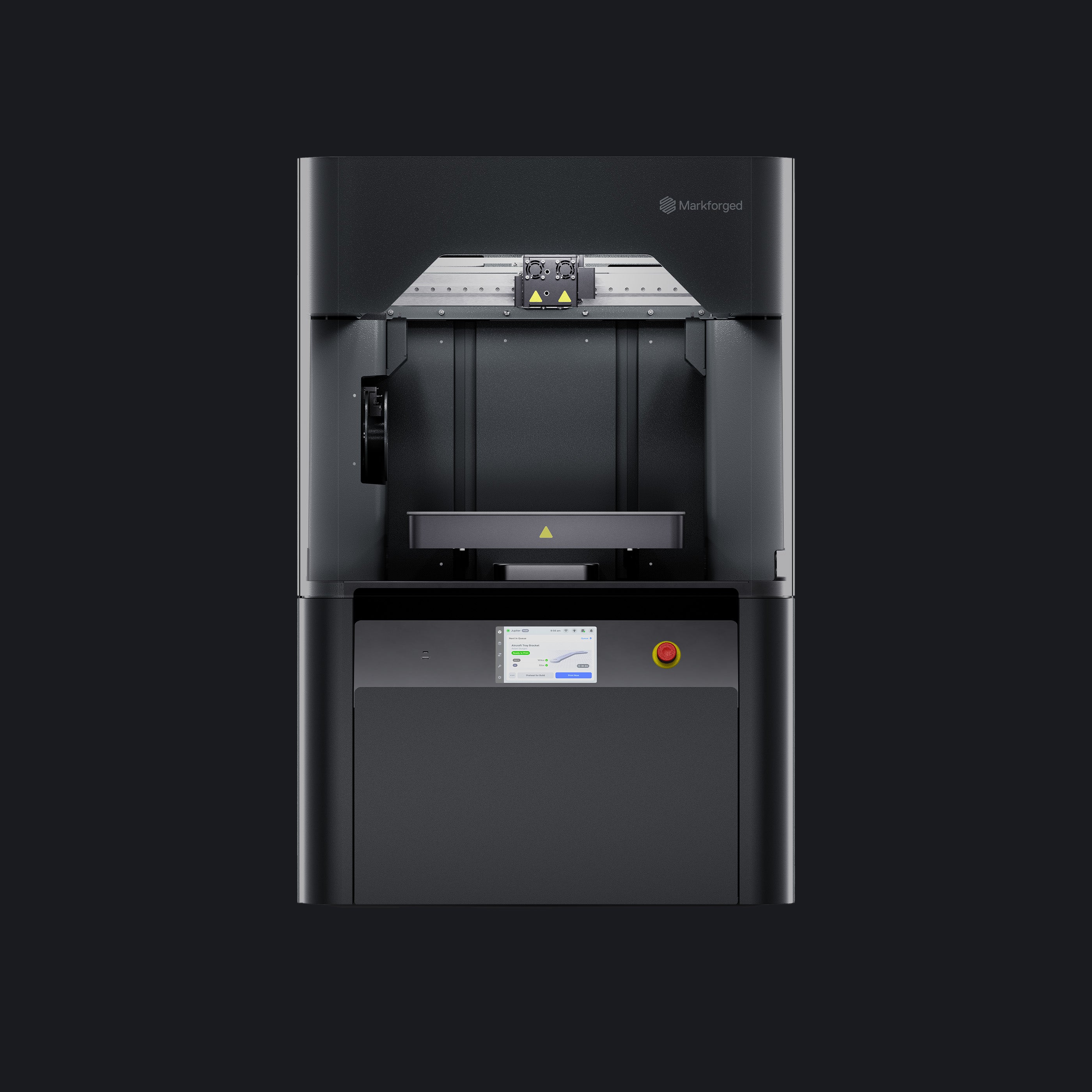

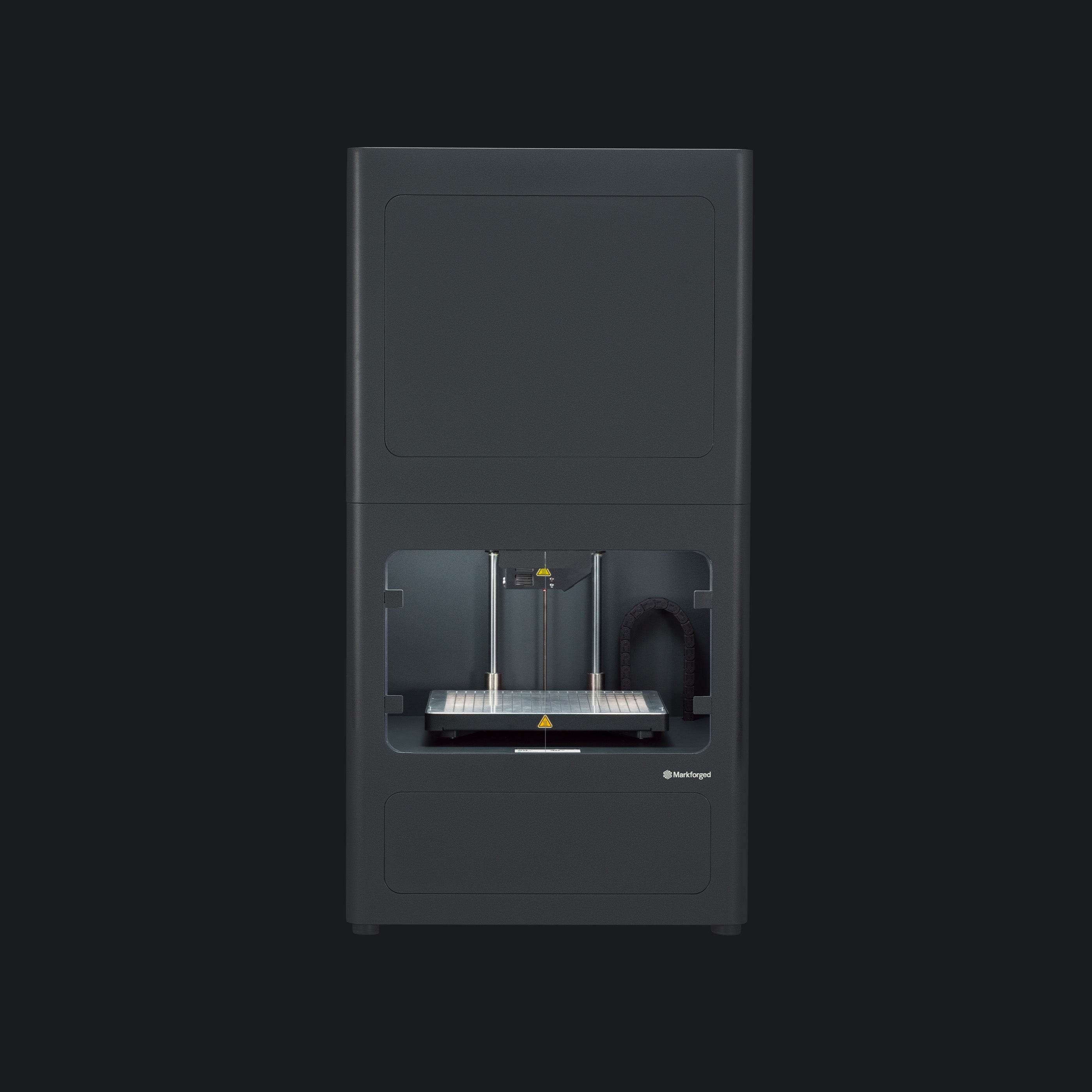

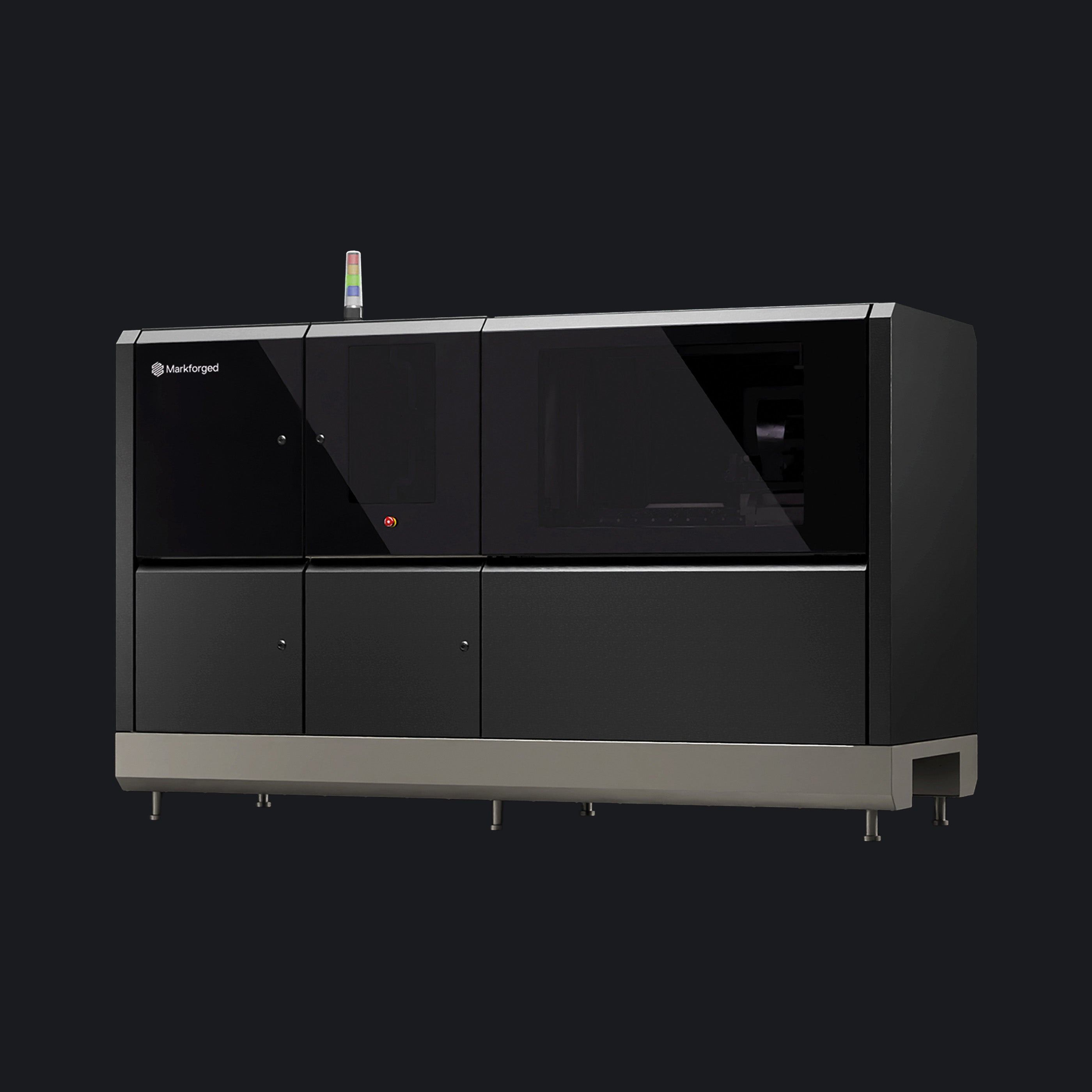

PX100™ Metal 3D Printer

Product Info

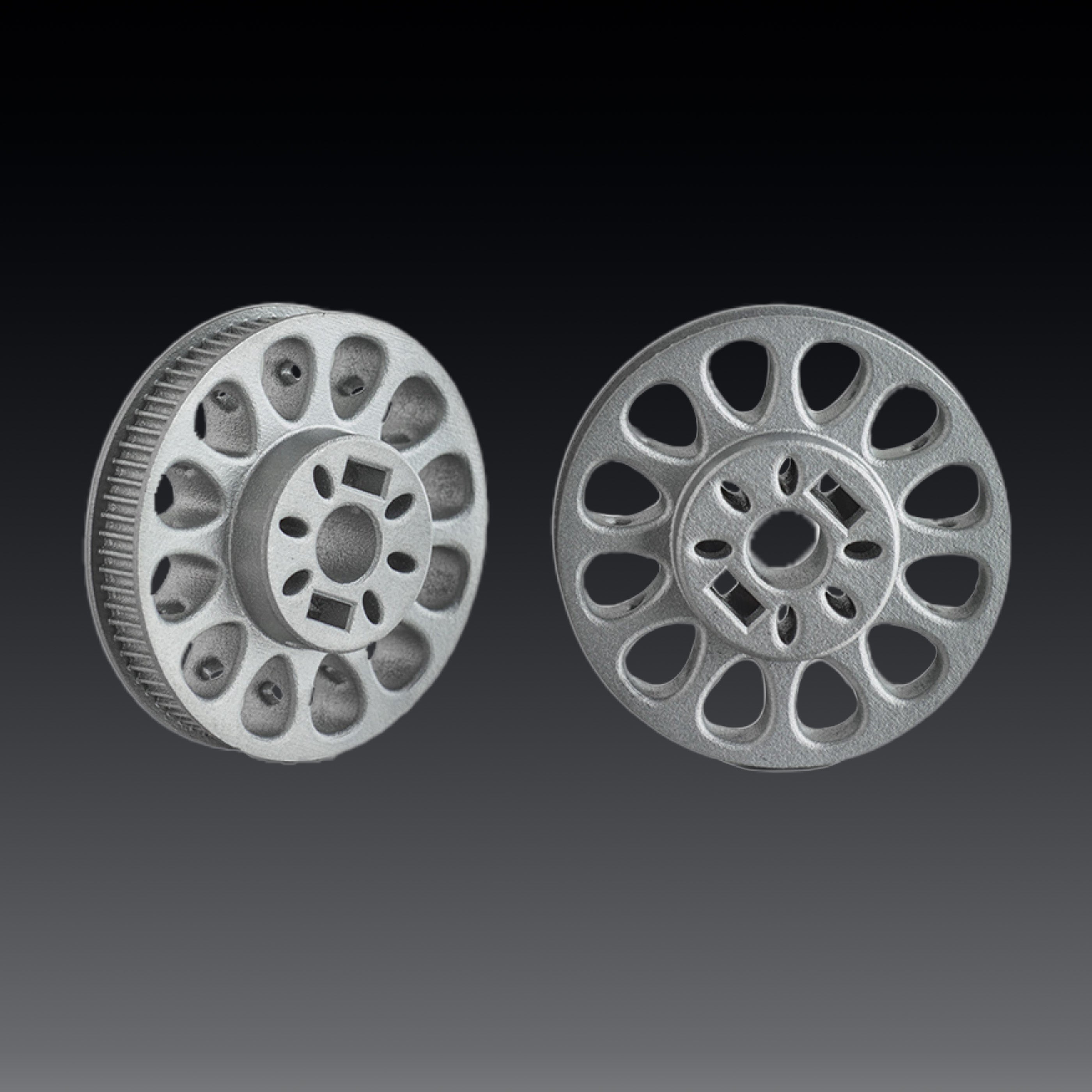

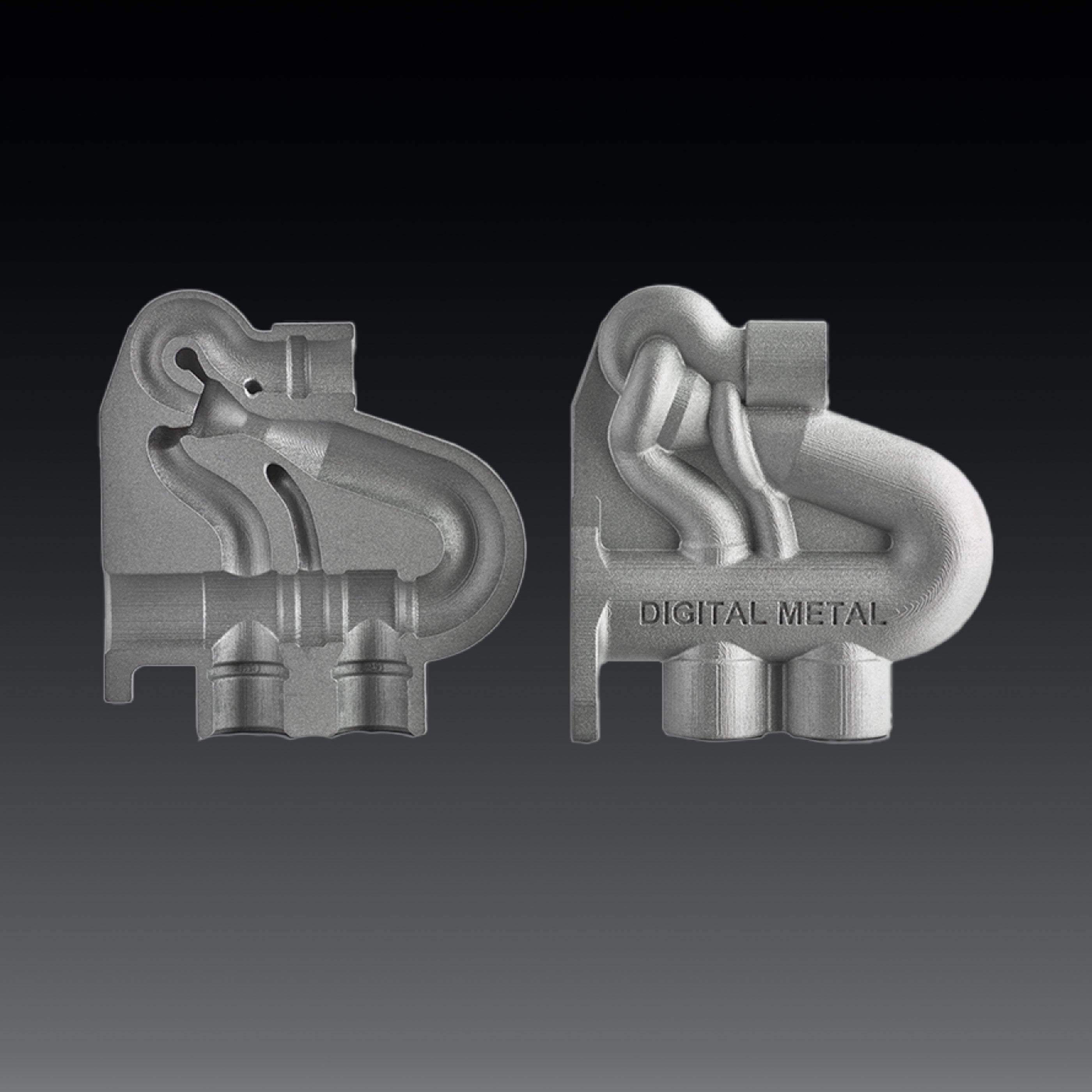

Additive Metal Production at Unmatched Precision

The PX100™ is a precise, reliable Binder Jetting machine built on nearly two decades of proven excellence, combining production speed additive fabrication with industry-leading part resolution. It comprises one part of the PX100™ system, which includes powder handling machines and furnaces to deliver end-to-end production capabilities. The system is highly configurable and has a wide range of available materials.

Country of Origin: Sweden

System Details

Outstanding Productivity

- Capable of print speeds up to 61 in³ per hour (approx. 1,000 cm³)

- Printhead with 70,400 nozzles delivering 2pL droplets at 15.5 kHz

- Easily exchangeable powder magazine for fast material & build changeover

Detailed Precision and Quality

- Static accuracy better than 0.00004 inches (approx. 1µm)

- 1600 dpi resolution with industry-leading accuracy and repeatability

- Robust machine design minimizes downtime and unscheduled stops

Built for Your Needs

- Fully customizable, open system

- Equipped for future updates, such as inertization and automation modules

- Optimized powder utilization: close to 100% of excess powder is recycled

Technical Data

| Specification | Details |

|---|---|

| Printing System | Full-width print system with 70,400 ink nozzles |

| Machine Footprint (L x W x H) | 106.3" (2700 mm) x 39.4" (1000 mm) x 66.9" (1700 mm) |

| Build Volume (L x W x H) | 10.25" (260.5 mm) x 8.68" (220.5 mm) x 7.32" (186 mm) |

| Weight | 4,409 lbs (2,000 kg) |

| Typical Productivity | 500 – 1,000 cm³/h |

| Power Consumption | 3.5 kW (average) |

| Material Deposition | Recoating with powder applicator |

| Material Recirculation | Yes, with no degradation |

Precise. Reliable. Proven.

The culmination of nearly 20 years of development by Digital Metal®. It draws upon a platform that has produced hundreds of thousands of high-quality components.

Materials

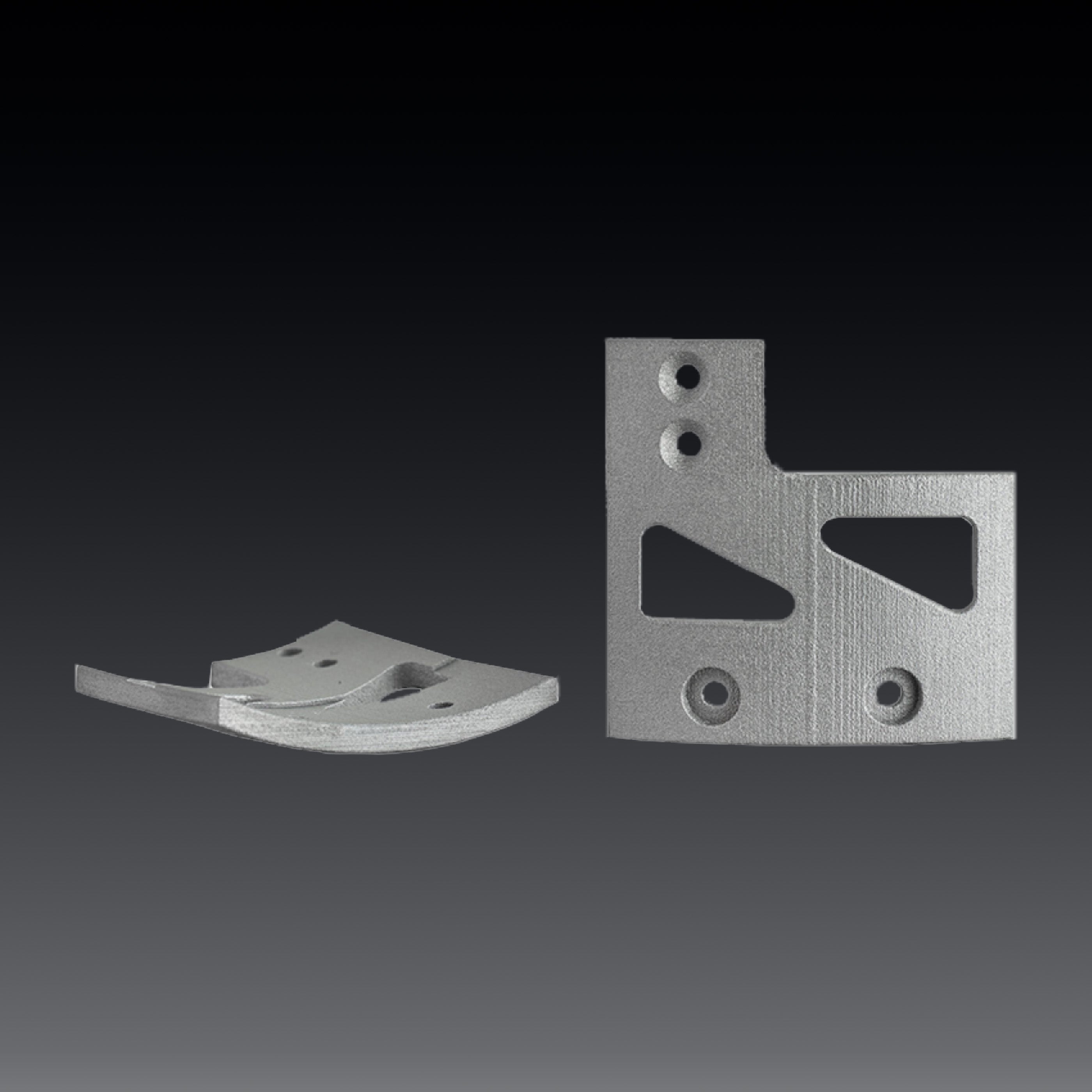

316L Stainless Steel

316L Stainless Steel is an austenitic low-carbon stainless steel known for excellent corrosion resistance and ductility.

It is a versatile material used in a variety of industries and applications including dental, medical, consumer electronics, aerospace, marine, and designer textiles.

Ti-6Al-4V*

Ti-6Al-4V is a titanium alloy that combines high strength, hardness, and ductility with high corrosion resistance. It nearly matches steel’s strength while being 45% lighter, yielding one of the highest strength to weight ratios in manufacturing materials.

Aerospace applications are the most common, but Ti-6Al4V is also used in marine, automobile, energy, chemical and biomedical industries.

17-4PH Stainless Steel*

17-4PH is a precipitation-hardening martensitic stainless steel known for its high strength, wear resistance, corrosion resistance, and weldability.

This versatile material is widely used in diverse industries such as petroleum, chemical, and aerospace. It is commonly employed for heavy-duty machine components, couplings, screws, drive shafts, and nuts. Additionally, 17-4PH can be heat-treated to meet specific mechanical requirements.

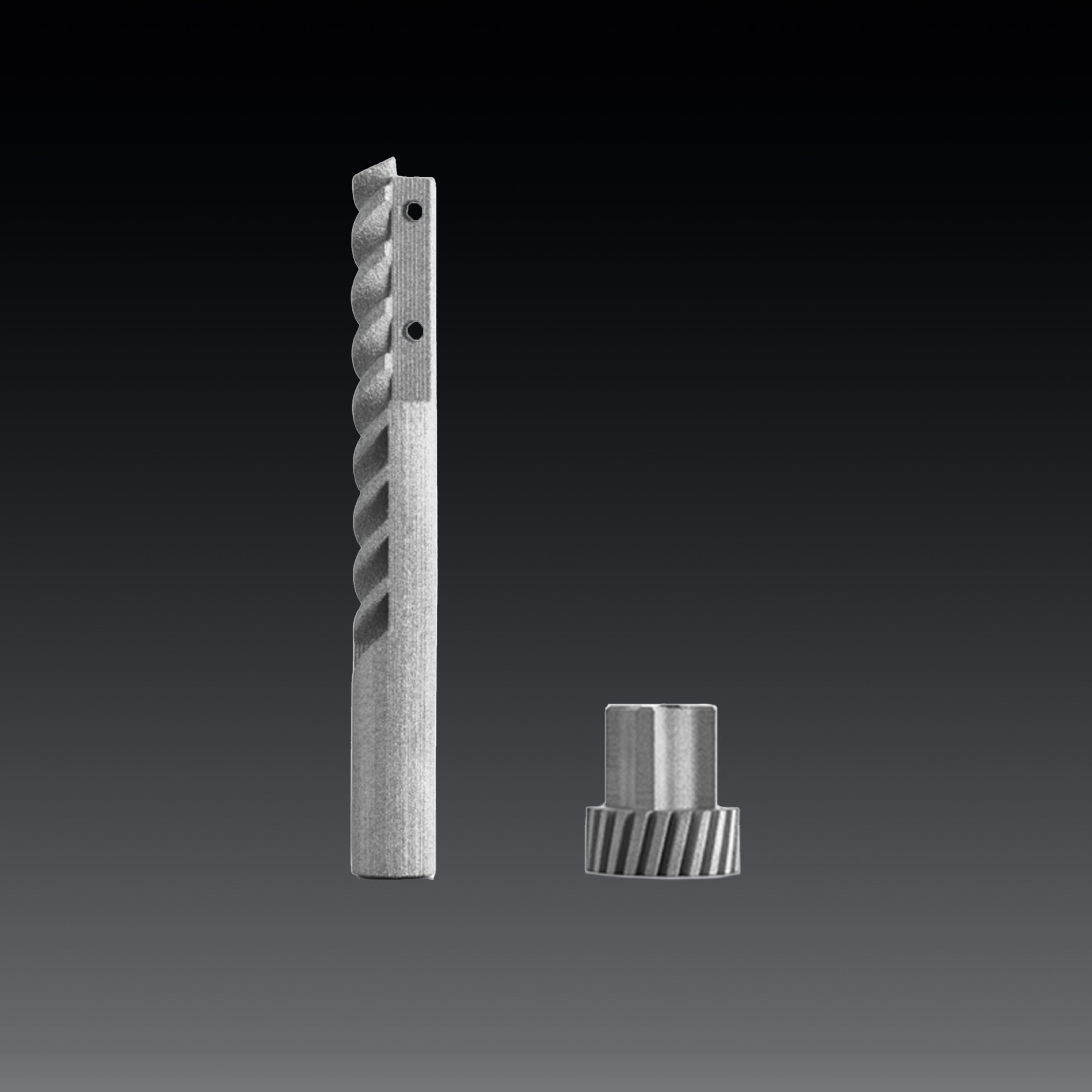

D2 Tool Steel*

D2 is an air-hardening tool steel celebrated for its exceptional hardness and abrasion resistance while maintaining moderate toughness.

It's primarily used in the manufacture of cutting and forming tools, including shear cutters, punches, dies, and stamping tools. D2 steel remains stable throughout heat treatments, allowing for the fine-tuning of its final properties after sintering.

H13 Tool Steel*

H13 is a high-performance hot work tool steel noted for its excellent thermal fatigue resistance, hardenability, wear resistance, and toughness. It's commonly used in both hot and cold work tooling but is particularly well-suited for hot work applications due to its exceptional properties.

H13 is harder and more abrasion-resistant than most mild and stainless steels, yet less hard than other tool steels like D2. Its combination of properties makes it a versatile and reliable choice for a range of applications.

4140 Low Alloy Steel*

4140 is a low-alloyed steel recognized for its high strength, hardenability, and toughness. It's commonly used to produce gears, pulleys, and fasteners in the automotive and machinery industries, where precise and robust components are crucial.

Additionally, 4140 can be easily machined and welded, and it can be heat-treated to further enhance its mechanical properties.

IN625 Nickel Superalloy*

IN625 is a high-performance nickel based superalloy known for its toughness and excellent corrosion resistance in both oxidizing and reducing environments. It is more corrosion-resistant and can be used in higher temperatures than IN718, but exhibits inferior mechanical properties.

It is well suited for a variety of demanding applications in chemical processing, aerospace and marine engineering, power generation, and oil/gas. The material is notoriously difficult to machine, making 3D printing an attractive alternative.

IN718 Nickel Superalloy*

IN718 is a high-performance nickel-based superalloy known for its excellent strength and good corrosion resistance at elevated temperatures.

It is stronger and harder than IN625 but offers less corrosion resistance and a lower maximum operating temperature.

IN718 alloys are commonly utilized in aerospace applications, including turbines, spacecraft, rocket engines, turbo pumps, and tooling.

M247 Nickel Superalloy*

M247 is a high-performance nickel-based superalloy with exceptional thermomechanical properties.

The material is closely related to IN625 and IN718 and displays remarkable inherent oxidation resistance, as well as outstanding strength and creep resistance at high temperatures.

It is particularly well-suited for use in demanding applications such as aerospace and gas turbine engines, combustion/exhaust systems, turbopump impellers, and other similar high-temperature environments.

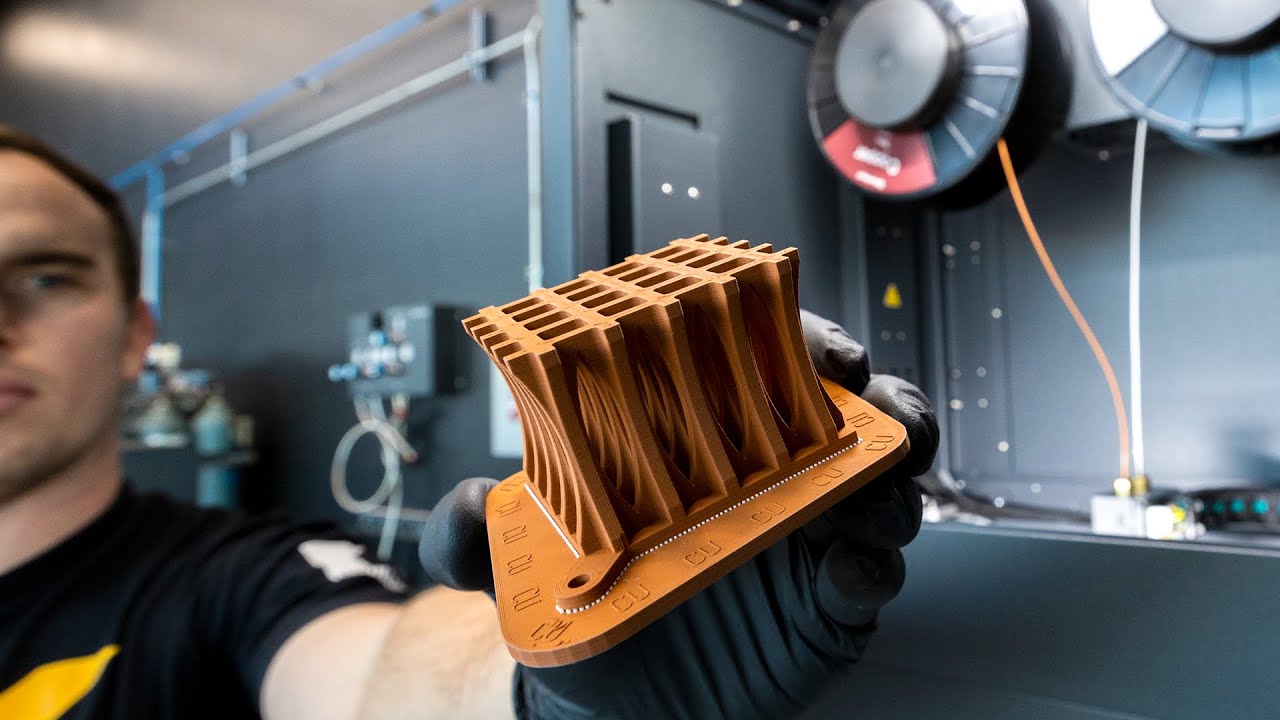

Copper*

Copper is a 99.9% commercially pure material with excellent electrical and thermal conductivity properties.

It is mostly used for electronics, heat exchangers, heat sinks, engine parts, as well as in a variety of industry applications that require good conductivity.

Printing in copper offers freedom of design and enables optimal functionality with few restrictions.

*Material not yet compatible with PX100™. Support for remaining metals will be added over time.

Simple and safe workflow designed for any business.

Why Choose Markforged?

Unlock Next-Level Precision and Innovation in Your Shop with 3D Printing.

Innovative Technologies

Markforged's innovations like carbon fiber reinforcement, integrated laser scanning quality control, and part simulation software evolved 3D printing from prototyping to the factory floor.

Strong, Precise Parts

Precision engineering printing hardware, advanced composite materials and carbon fiber reinforcement enable Markforged 3D printers to generate accurate, industrial-strength parts with beautiful surface finish time after time.

"Just Press Print" Simplicity

Markforged tightly integrates 3D printing hardware, materials, and intuitive software, making printing industrial-quality parts easy for non-experts on the shop floor.

Industrial Reliability

Markforged's industrial 3D printers are famed for their reliability, which is why over 5,000 manufacturing facilities across the world rely on Markforged to keep lines running and customers satisfied.

Scalability and Flexibility

The Digital Forge is designed to scale, catering to both small businesses and large enterprises. Whether you need one printer or a fleet, the platform scales to meet your production demands without the need for extensive retooling or setup changes.