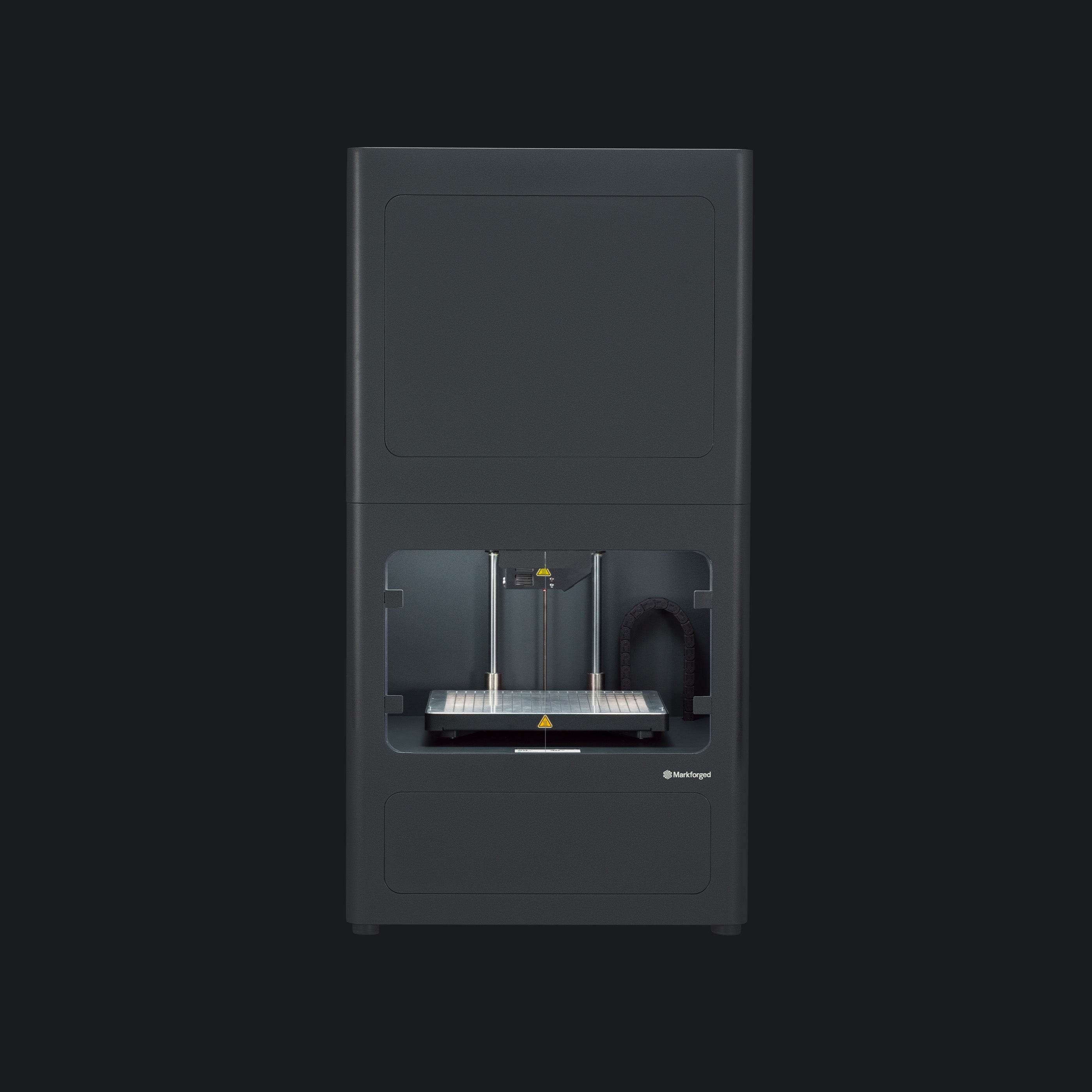

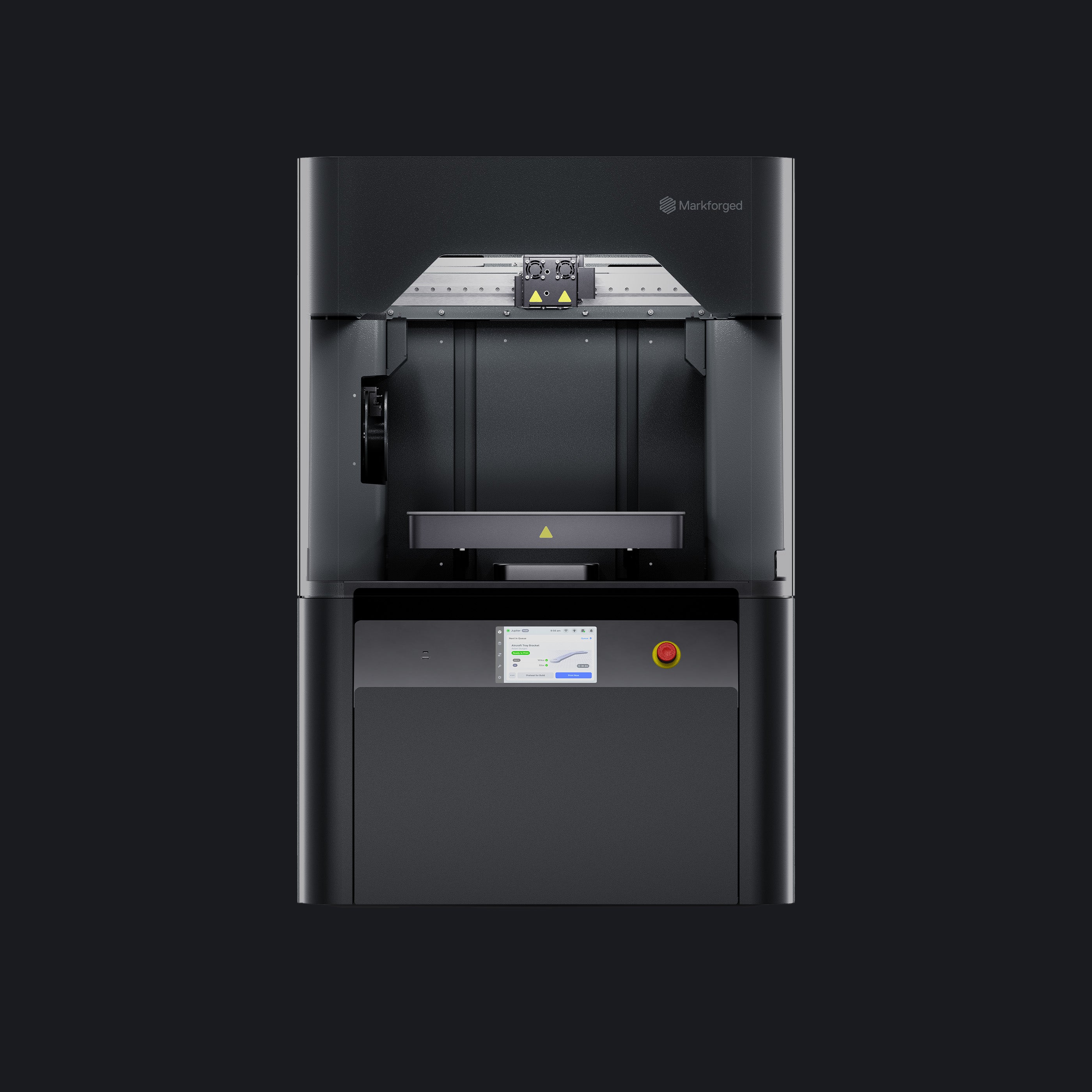

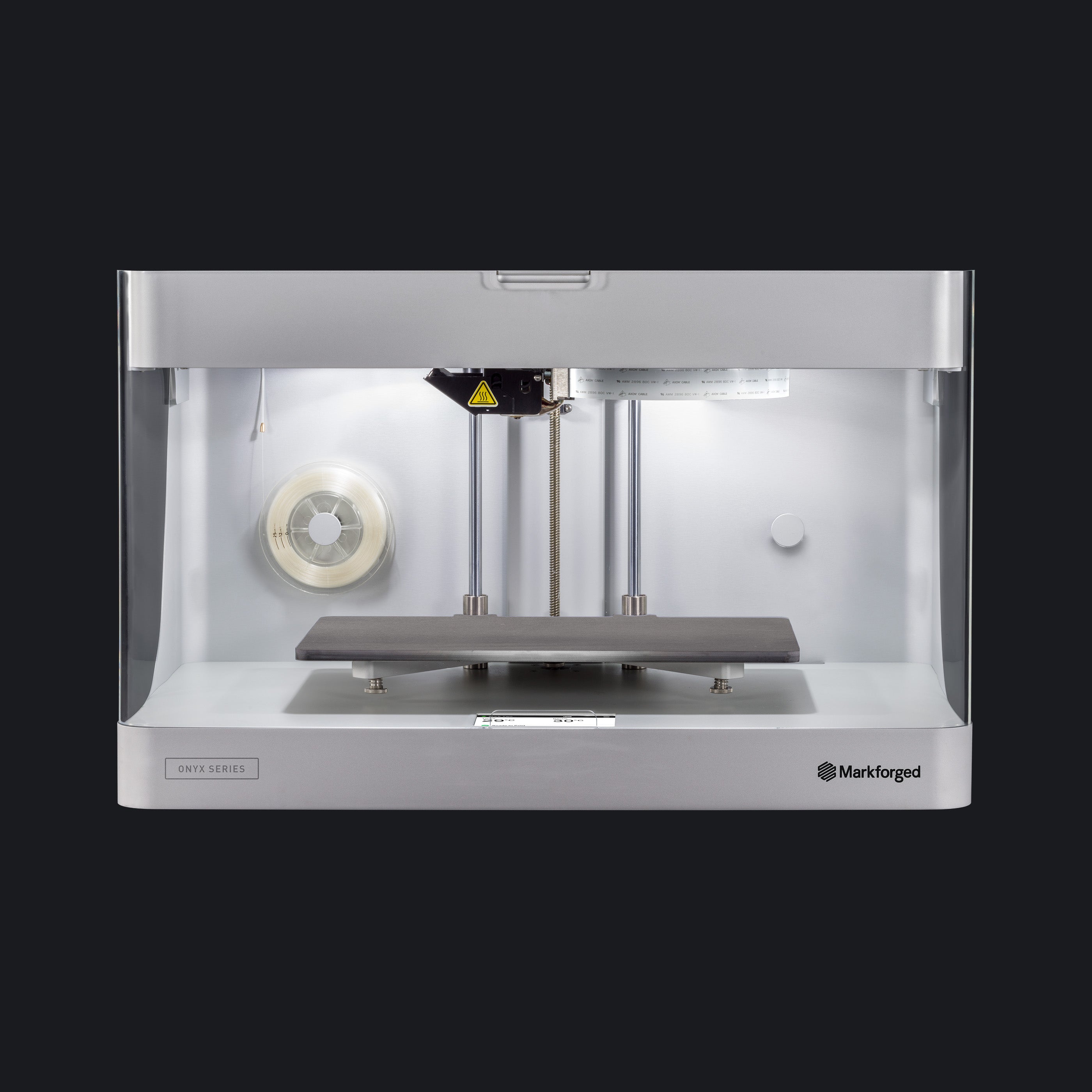

Mark Two™ Desktop Composite 3D Printer

Financing options available.

Product Info

Precision-Built So You Can 3D Print Precise Parts

The Mark Two™ is the award-winning professional carbon fiber composite 3D printer – built around the Continuous Fiber Reinforcement (CFR) process to reliably produce strong parts for you. It’s built around an aluminum unibody frame that delivers high accuracy and repeatability. A hardened extrusion system enables the Mark Two™ to print Onyx® — a micro carbon fiber filled nylon filament that destroys traditional extrusion systems — reliably over thousands of print hours. The machine is built to be easy to operate and maintain — from easy-to-reach wear components (like nozzles and feed tubes) to usability focused features like the print bed, which can be removed and replaced with 10 μm repeatability.

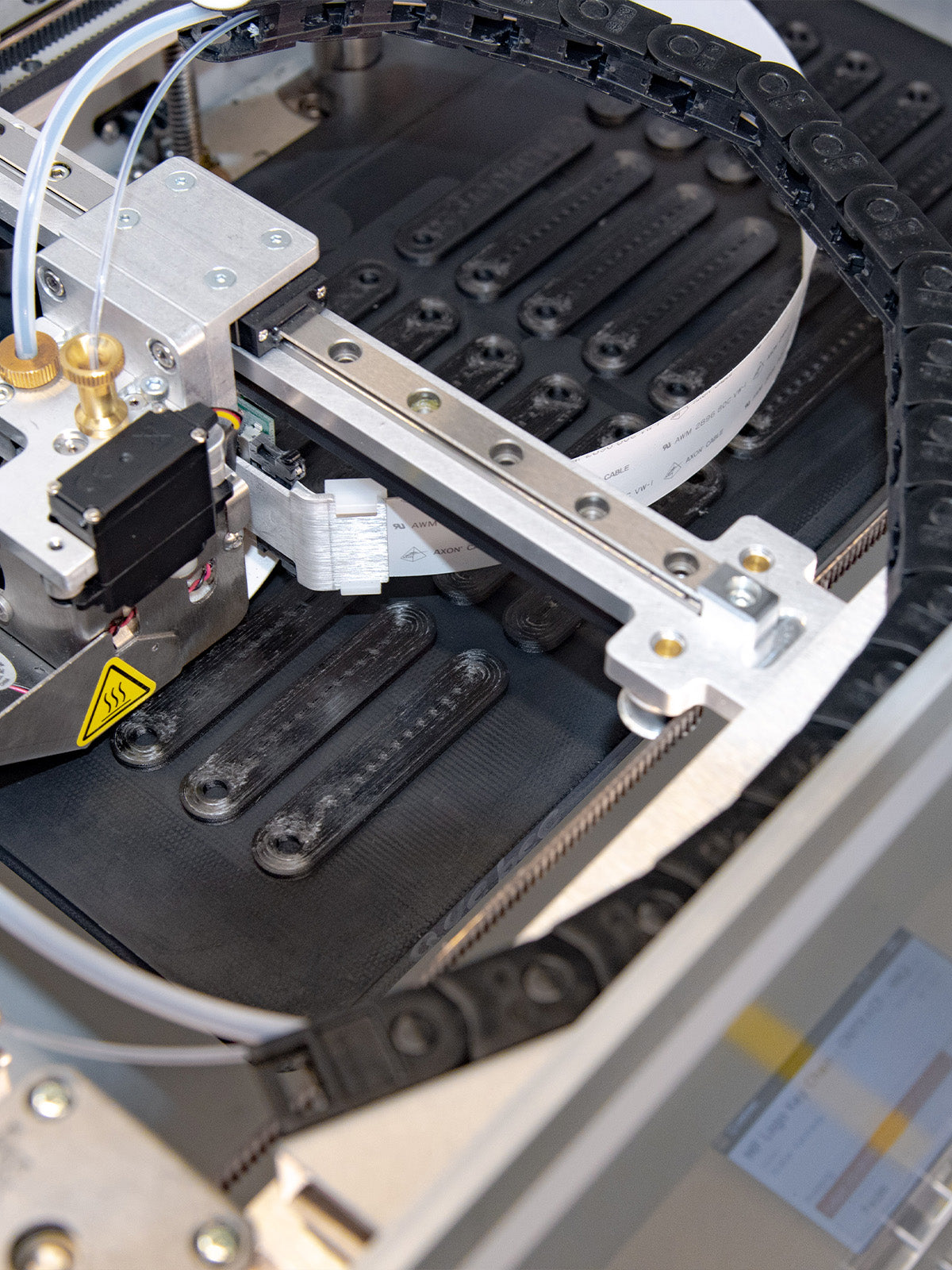

In addition to more common FFF features, the Mark Two™ has a 2nd-generation fiber reinforcement system that enables you to lay down continuous fiber into parts. Markforged composite printers are capable of printing continuous fiber reinforced parts, which can be as strong as machined aluminum.

Country of Origin: Canada

Technical Data

| Specification | Details |

|---|---|

| Printing Process | Continuous Fiber Reinforcement (CFR) |

| Z Layer Resolution | 0.004" - 0.008" (100 μm - 200 μm) |

| Printing Media | Composite Base Filaments, Continuous Fibers |

| Internal Part Geometry | Closed Cell Infill with Continuous Fiber Reinforcement |

| Print Bed | Precision Ground Composite |

| Physical Dimensions | Width: 23.0" (584 mm), Depth: 13.0" (330 mm), Height: 14.0" (355 mm) |

| Weight | 35 lbs (16 kg) |

| Build Volume | Width: 12.6" (320 mm), Depth: 5.2" (132 mm), Height: 6.1" (154 mm) |

3D-Printed Precision

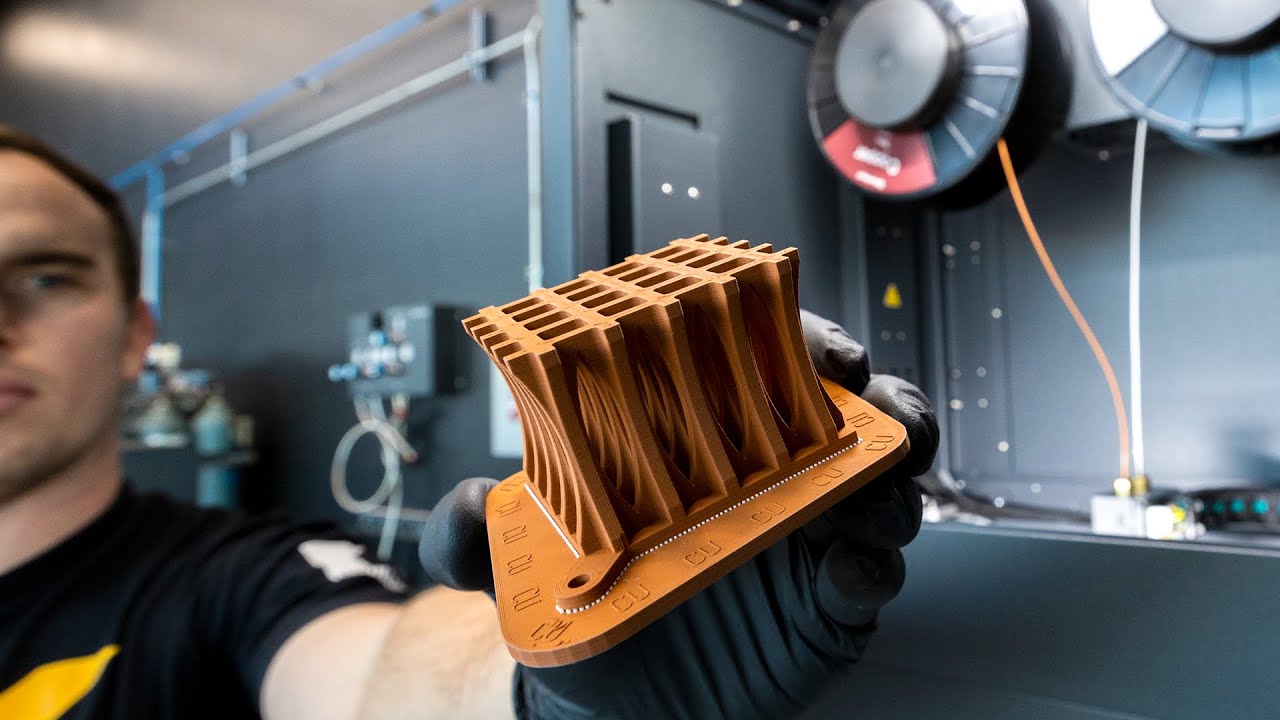

The power of Continuous Carbon Fiber at your fingertips.

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Print precise parts with best-in-class surface finish thanks to Onyx®, Markforged®’s extremely versatile micro carbon fiber filled nylon material.

Print Continuous Carbon Fiber reinforced parts on your desktop – stiff, strong, extremely durable, and capable of replacing machined aluminum.

A unibody aluminum chassis and precision-machined components deliver lights-out reliability over thousands of print hours.

Print precise parts with best-in-class surface finish thanks to Onyx®, Markforged®’s extremely versatile micro carbon fiber filled nylon material.

Materials

Onyx® (Plastic)

Onyx® — the flagship Composite Base material — is a micro carbon fiber filled nylon that yields accurate parts with near flawless surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

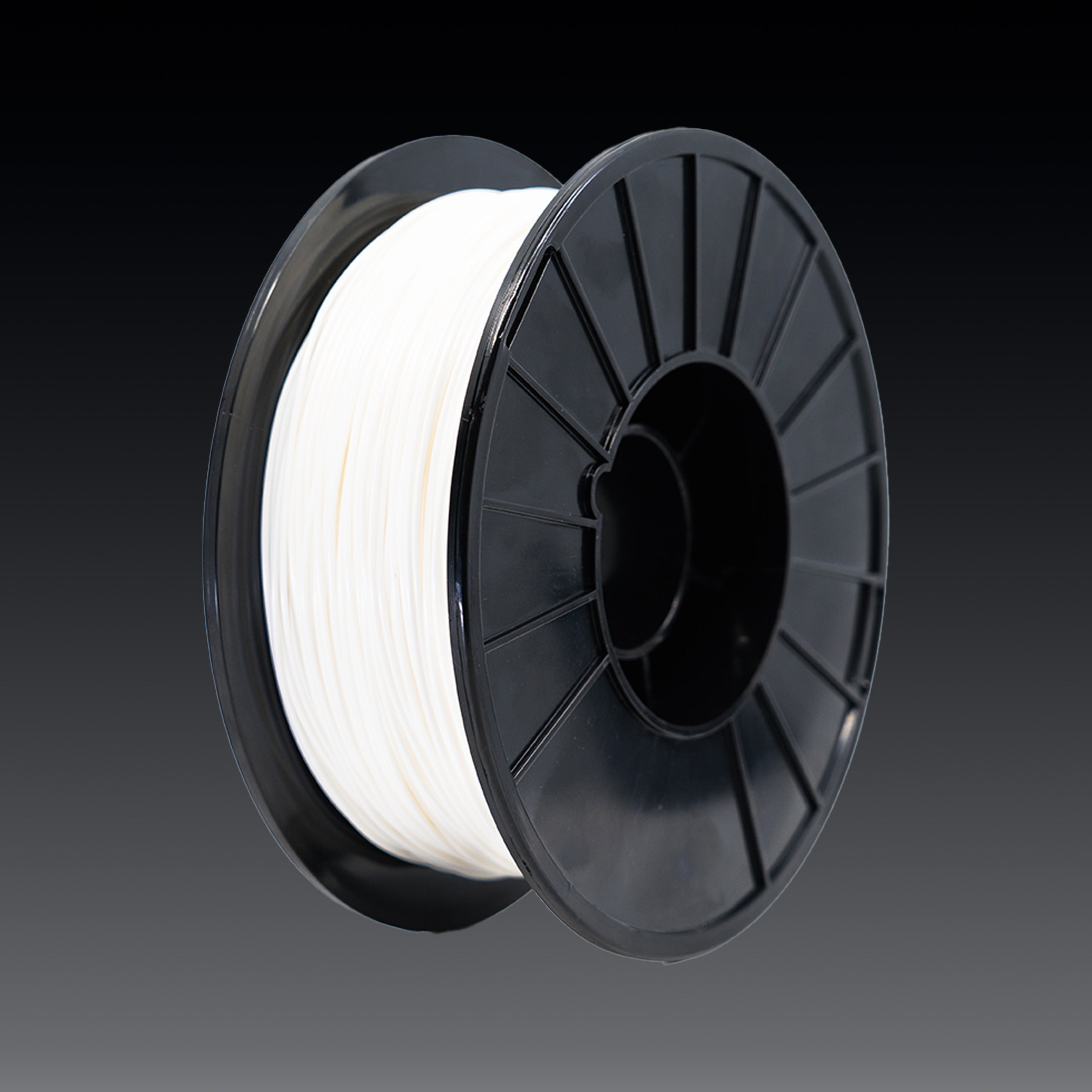

Nylon

Nylon is an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Smooth TPU 95A

Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand.

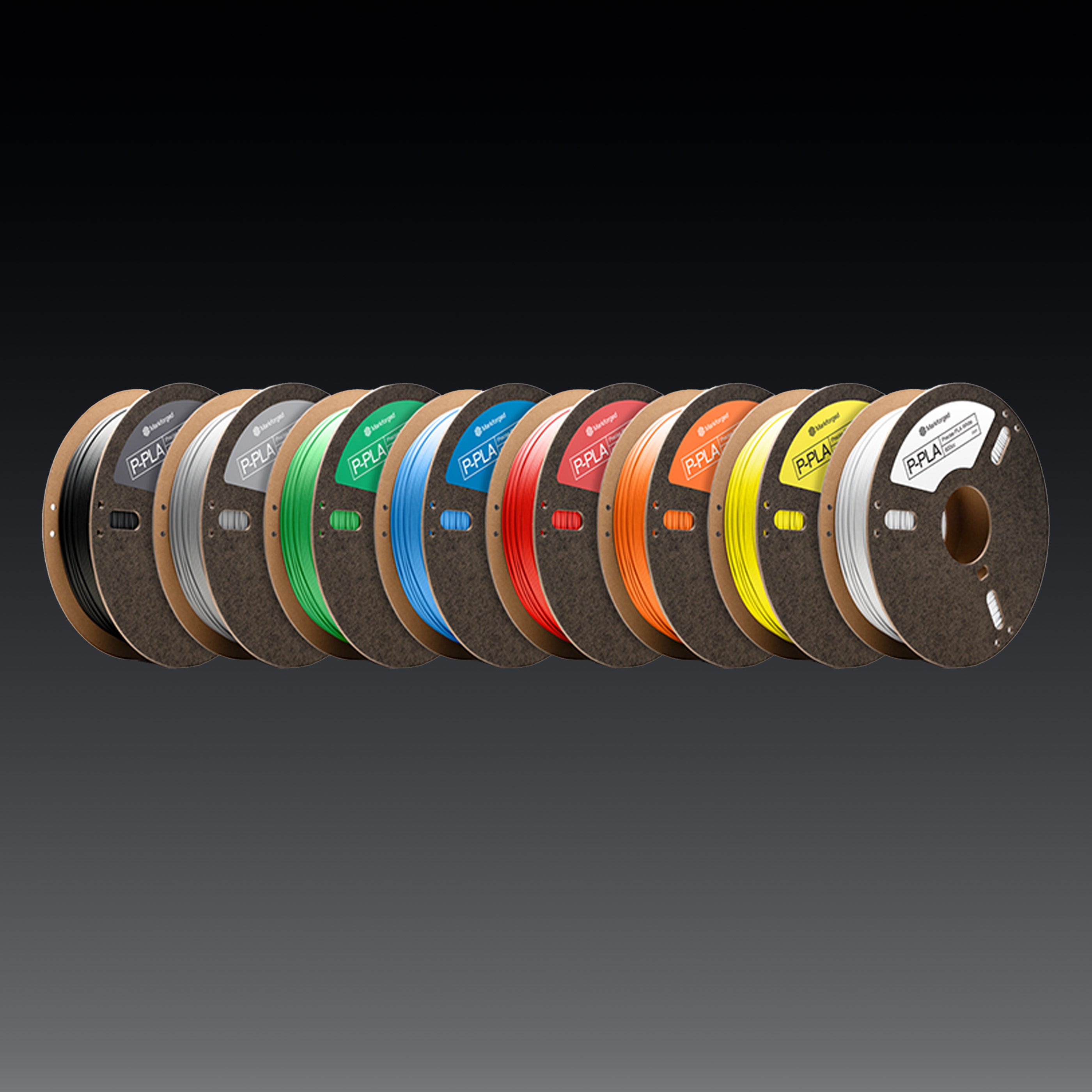

Precise PLA

Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation.

Carbon Fiber

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers. A special Carbon Fiber variant is compatible with ULTEM™ 9085 Filament.

Fiberglass

Fiberglass is Markforged’s entry-level Continuous Fiber —a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. Fiberglass is the flagship material of the Onyx Pro and X5 and printable on the Mark Two and X7, providing a more affordable alternative to Carbon Fiber.

Aramid Fiber (Kevlar®)

Aramid Fiber is a Kevlar® based, specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

HSHT Fiberglass

High Strength High Temperature (HSHT) Fiberglass is defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures. As a result, HSHT reinforcement is best used for parts in high-temperature environments like molds, autoclaves, and others.

Simple and safe workflow designed for any business.

Why Choose Markforged?

Unlock Next-Level Precision and Innovation in Your Shop with 3D Printing.

Innovative Technologies

Markforged's innovations like carbon fiber reinforcement, integrated laser scanning quality control, and part simulation software evolved 3D printing from prototyping to the factory floor.

Strong, Precise Parts

Precision engineering printing hardware, advanced composite materials and carbon fiber reinforcement enable Markforged 3D printers to generate accurate, industrial-strength parts with beautiful surface finish time after time.

"Just Press Print" Simplicity

Markforged tightly integrates 3D printing hardware, materials, and intuitive software, making printing industrial-quality parts easy for non-experts on the shop floor.

Industrial Reliability

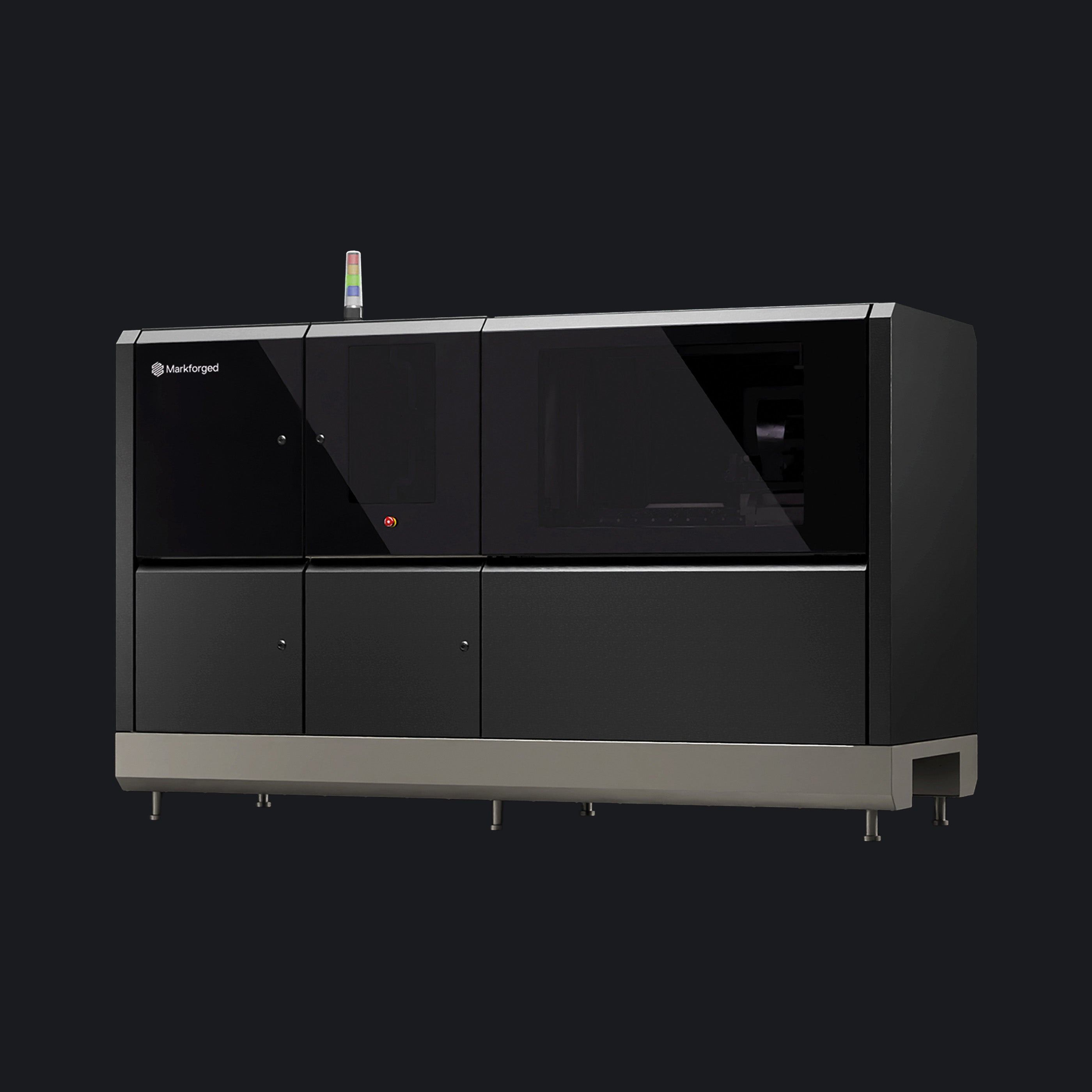

Markforged's industrial 3D printers are famed for their reliability, which is why over 5,000 manufacturing facilities across the world rely on Markforged to keep lines running and customers satisfied.

Scalability and Flexibility

The Digital Forge is designed to scale, catering to both small businesses and large enterprises. Whether you need one printer or a fleet, the platform scales to meet your production demands without the need for extensive retooling or setup changes.