FX20™ Industrial Composite 3D Printer

Financing options available.

Product Info

State-of-the-Art Hardware, Electronics, and Software

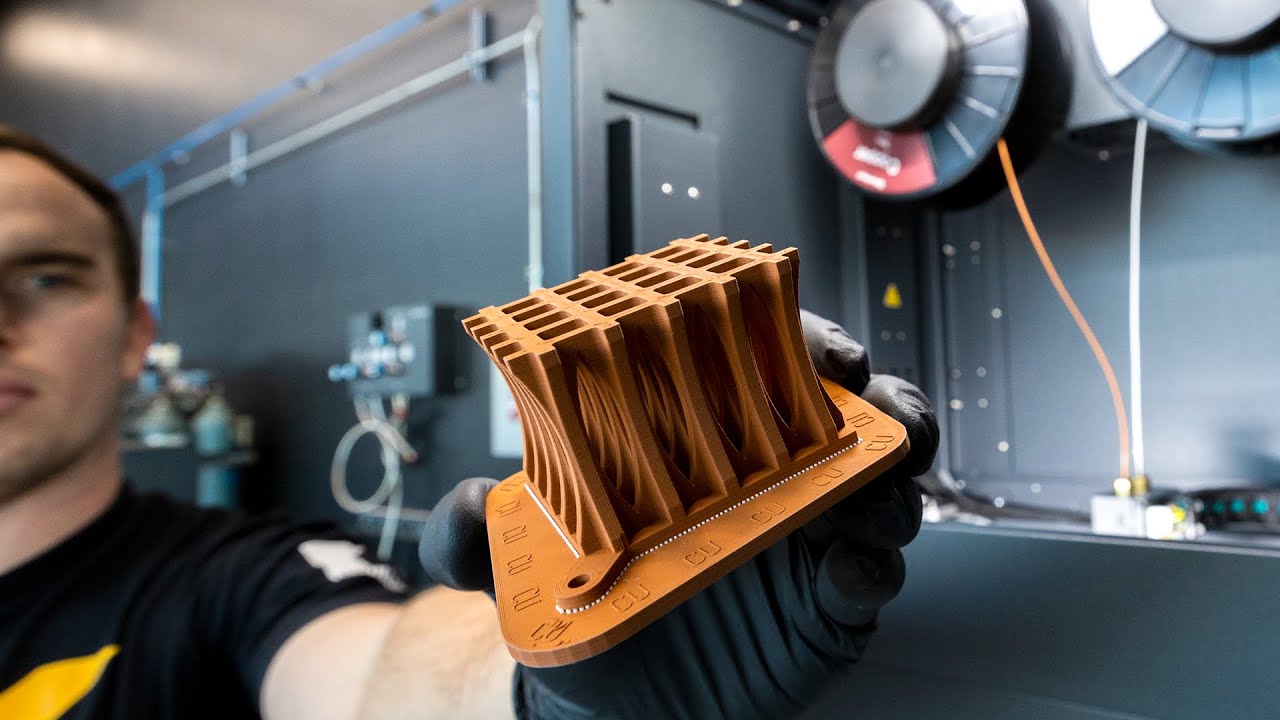

The FX20™ is the largest and most precise machine Markforged has ever produced.

This large format 3D printer features an 84L heated build chamber and massive, verified-flat vacuum bed with print sheets. The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately. FX20™’s turbo mode builds parts faster than any Markforged® machine, while new XL spools offer four times the material without spool changeover.

The FX20™ is remarkably easy to use. It features a 7 inch touchscreen from which users can control every aspect of the printer. Automated calibration and leveling reduces operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

Country of Origin: Canada

Technical Data

| Specification | Details |

|---|---|

| Printing Process | Fused Filament Fabrication, Continuous Fiber Reinforcement |

| Z Layer Resolution | 0.002" - 0.01" (50 μm - 250 μm) |

| Printing Media | Polymer Filament, Continuous Fibers |

| Internal Part Geometry | Closed Cell Infill with Continuous Fiber Reinforcement |

| Print Bed | Precision Machined Aluminum |

| Physical Dimensions | Width: 52.16" (1325 mm), Depth: 35.43" (900 mm), Height: 75.79" (1925 mm) |

| Weight | 1170 lbs (530 kg) |

| Single-Nozzle Build Volume | 20.67" (525 mm) x 15.75" (400 mm) x 15.75" (400 mm) |

| Multi-Nozzle Build Volume | 19.69" (500 mm) x 15.75" (400 mm) x 15.75" (400 mm) |

Production-Ready Performance

An ULTEM™ Filament capable large format 3D printer for big, strong, high temp parts — usable from factory floor to flight.

Materials

Onyx® (Plastic)

Onyx® — the flagship Composite Base material — is a micro carbon fiber filled nylon that yields accurate parts with near flawless surface finish. Few materials have the versatility of Onyx; it offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts. Today, there are more than a million Onyx parts in the field transforming manufacturing.

Vega™

Vega is Markforged’s first engineered high temperature plastic — an ultra high-performance carbon fiber filled PEKK for 3D printing critical aerospace parts. Vega can be reinforced with continuous fiber to achieve aluminum strength for replacing structural, non-critical aerospace components. It exhibits a smooth black matte surface finish that is excellent for production parts with minimal post processing.

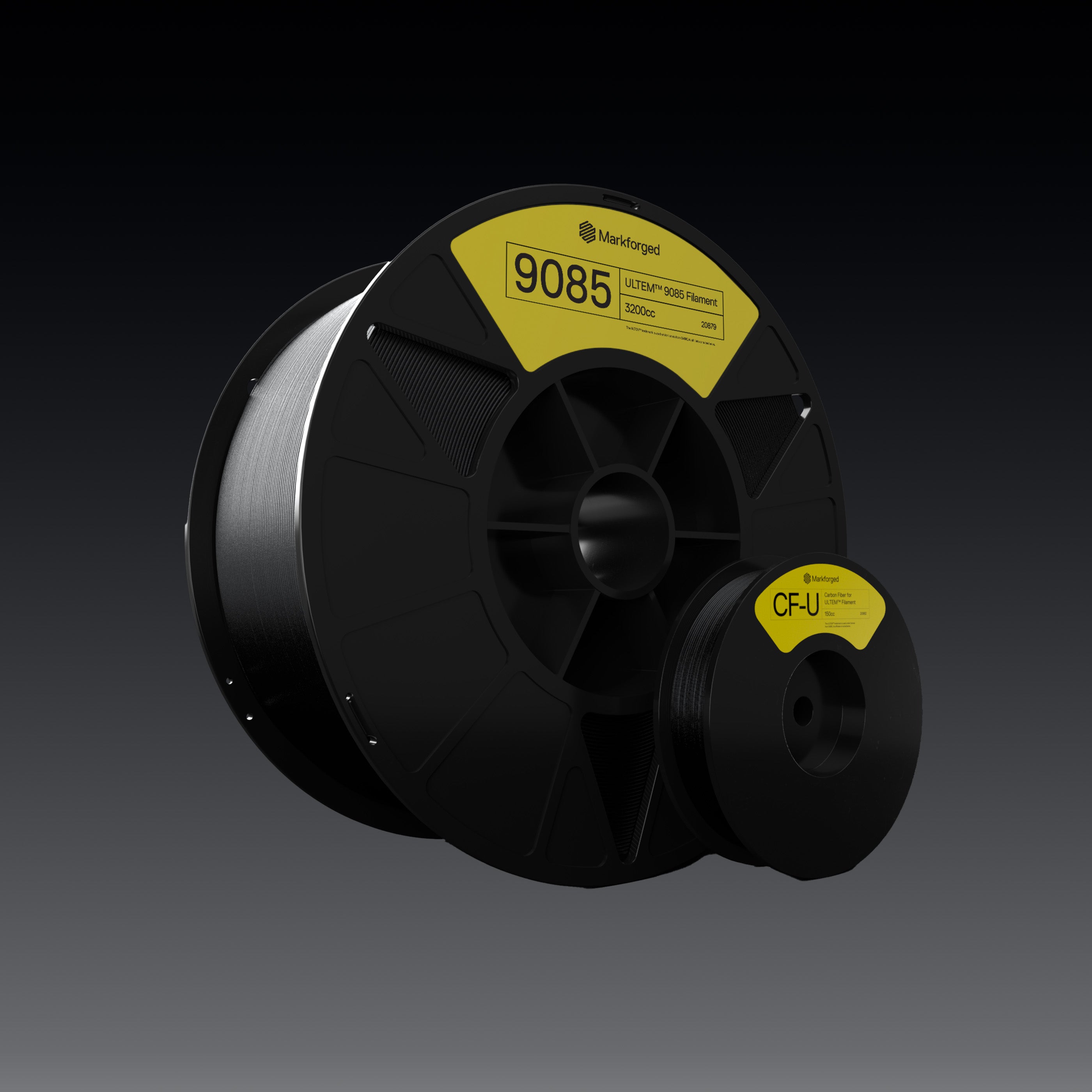

ULTEM™ 9085 Filament

ULTEM™ 9085 Filament is Markforged’s first high temperature printing polymer. It’s an extremely durable thermoplastic that exhibits excellent flame, smoke, and toxicity (FST) characteristics. Usable in production aerospace applications, ULTEM™ Filament brings Markforged’s CFR technology to a new realm of parts. ULTEM™ Filament is available in Markforged’s new 3200cc XL spool — four times larger than our standard spools.

Onyx FR™

Onyx FR is a flame-retardant variant of Onyx designed for use in applications where parts must be non-flammable. The material earned a UL Blue Card, and is considered V-0 (self extinguishing) at thicknesses greater than or equal to 3mm. It can be reinforced with any Continuous Fiber and is compatible with industrial composite 3D printers.

Carbon Fiber

Carbon Fiber is Markforged’s unique, ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries by Markforged 3D printers. A special Carbon Fiber variant is compatible with ULTEM™ 9085 Filament.

Carbon Fiber FR

Carbon Fiber FR is a flame-retardant variant of Markforged’s unique, ultra-high-strength Continuous Carbon Fiber — when used to reinforce a Composite Base material like Onyx FR, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be precisely laid down in a wide variety of geometries. Programmatically trace curved features, reinforce holes, and mimic unidirectional fiber layups — all within a few clicks.

Simple and safe workflow designed for any business.

Why Choose Markforged?

Unlock Next-Level Precision and Innovation in Your Shop with 3D Printing.

Innovative Technologies

Markforged's innovations like carbon fiber reinforcement, integrated laser scanning quality control, and part simulation software evolved 3D printing from prototyping to the factory floor.

Strong, Precise Parts

Precision engineering printing hardware, advanced composite materials and carbon fiber reinforcement enable Markforged 3D printers to generate accurate, industrial-strength parts with beautiful surface finish time after time.

"Just Press Print" Simplicity

Markforged tightly integrates 3D printing hardware, materials, and intuitive software, making printing industrial-quality parts easy for non-experts on the shop floor.

Industrial Reliability

Markforged's industrial 3D printers are famed for their reliability, which is why over 5,000 manufacturing facilities across the world rely on Markforged to keep lines running and customers satisfied.

Scalability and Flexibility

The Digital Forge is designed to scale, catering to both small businesses and large enterprises. Whether you need one printer or a fleet, the platform scales to meet your production demands without the need for extensive retooling or setup changes.