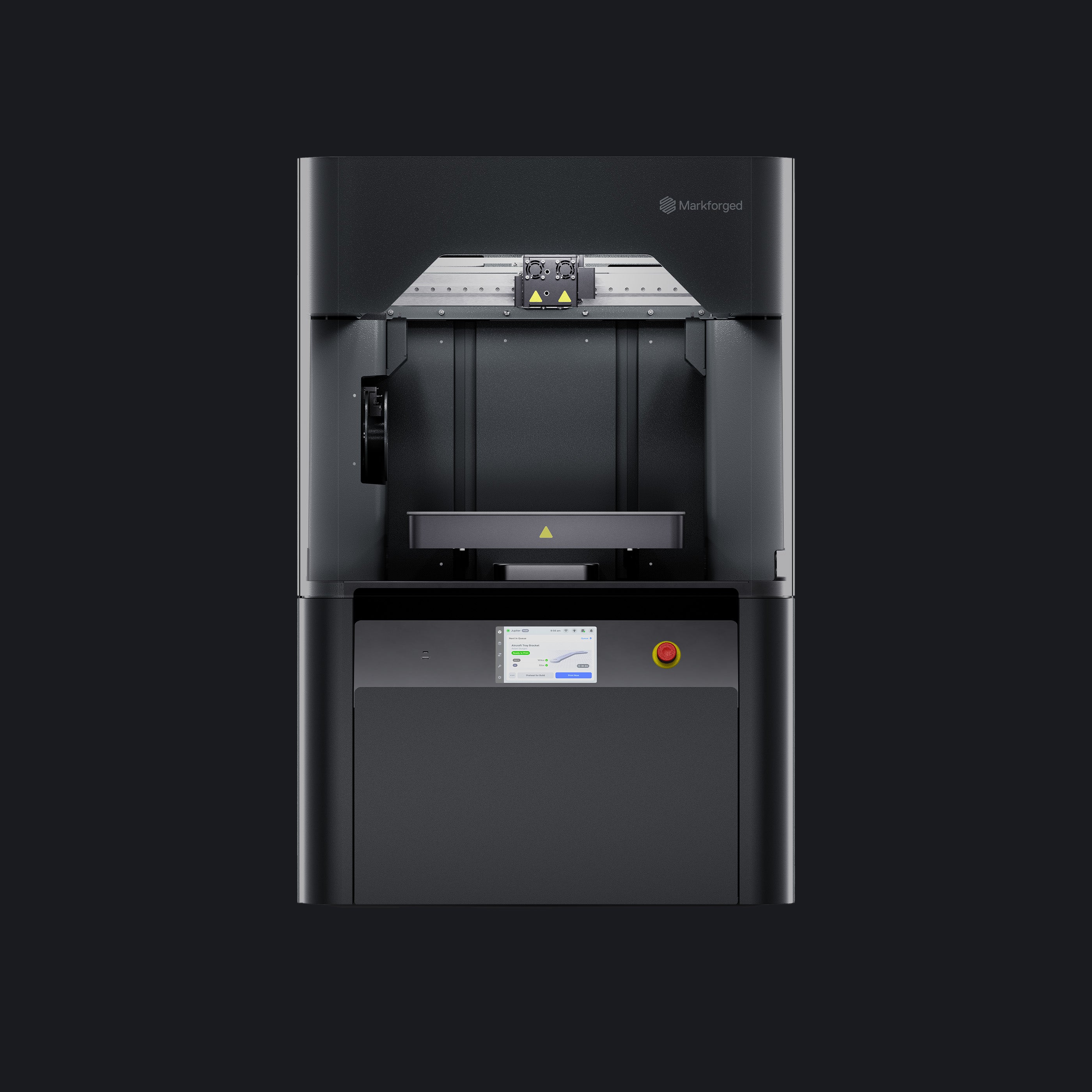

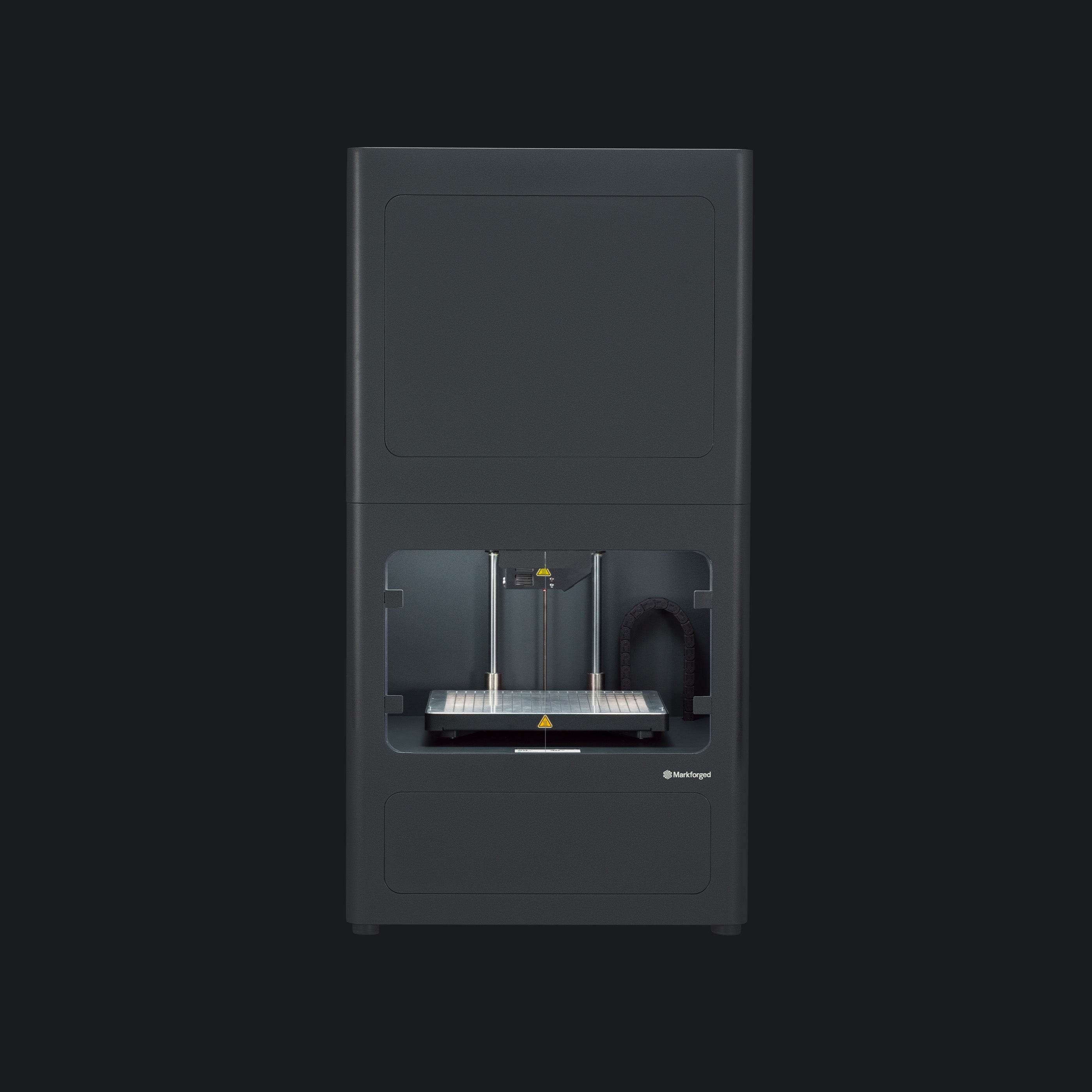

Metal X™ Metal 3D Printer

Financing options available.

Product Info

Revolutionizing Metal 3D Printing

The Markforged® Metal X™ is changing the game in metal 3D printing with its innovative approach that mixes metal powder with a plastic matrix. This not only ramps up safety but also makes it a breeze to set up in regular shops without needing hefty upgrades. It's kitted out with all the bells and whistles like a precision-engineered gantry, a heated chamber, and top-notch extrusion hardware, all designed to crank out tough and precise parts easily. Plus, it's super user-friendly with straightforward maintenance and quick swaps for consumables.

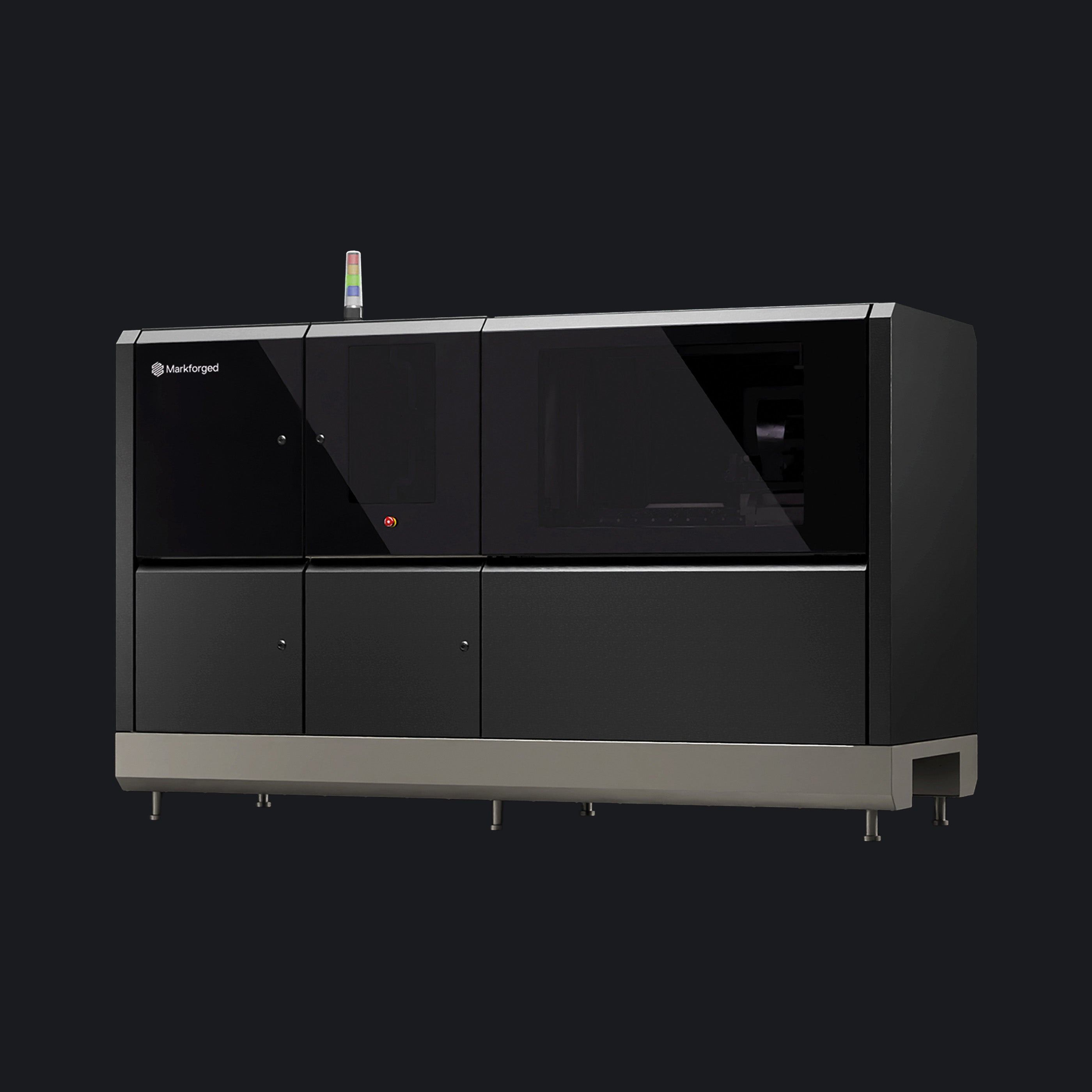

The Metal X™ System's Wash and Sinter machines play a key role in knocking out top-notch parts, ensuring everything is cleaned up and fused just right.

Country of Origin: Canada

Technical Data

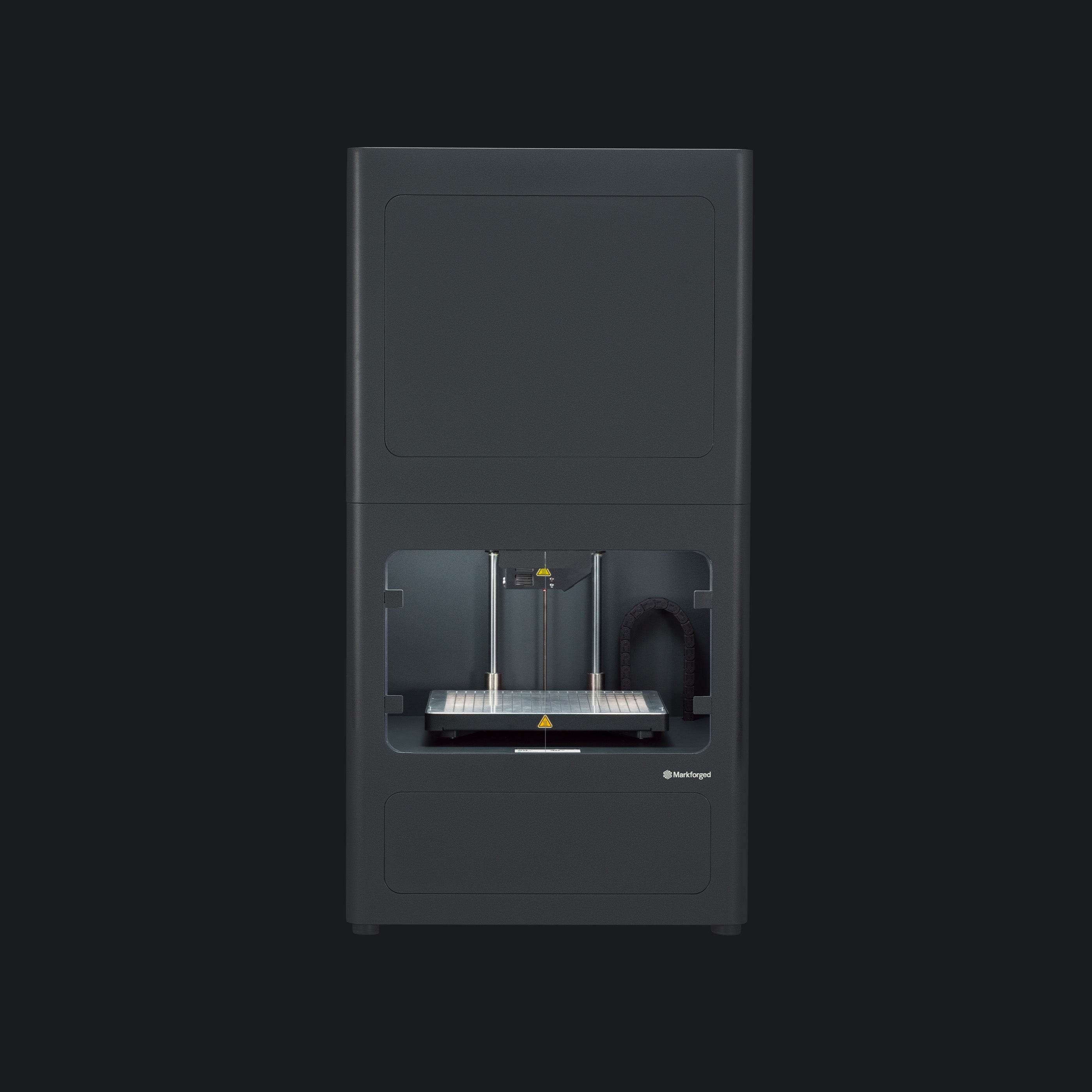

| Specification | Details |

|---|---|

| Printing Process | Metal FFF |

| Z Layer Resolution | 0.0033" - 0.0067" (85 μm - 170 μm Post-Sinter) |

| Printing Media | Bound Powder Filament |

| Internal Part Geometry | Closed Cell Infill (Triangular) or Solid Parts |

| Print Bed | Heated, Auto Leveling, Replaceable Print Sheets |

| Physical Dimensions | 22.64" x 18.39" x 44.09" (575 mm x 467 mm x 1120 mm) |

| Weight | 165 lbs (75 kg) |

| Build Volume | 11.81" x 8.66" x 7.09" (300 mm x 220 mm x 180 mm) |

Next Day Metal Parts

From design to fully functional metal parts in as few as 28 hours.

Materials

From stainless steel to copper, choose from a wide range of strong, durable, and capable materials.

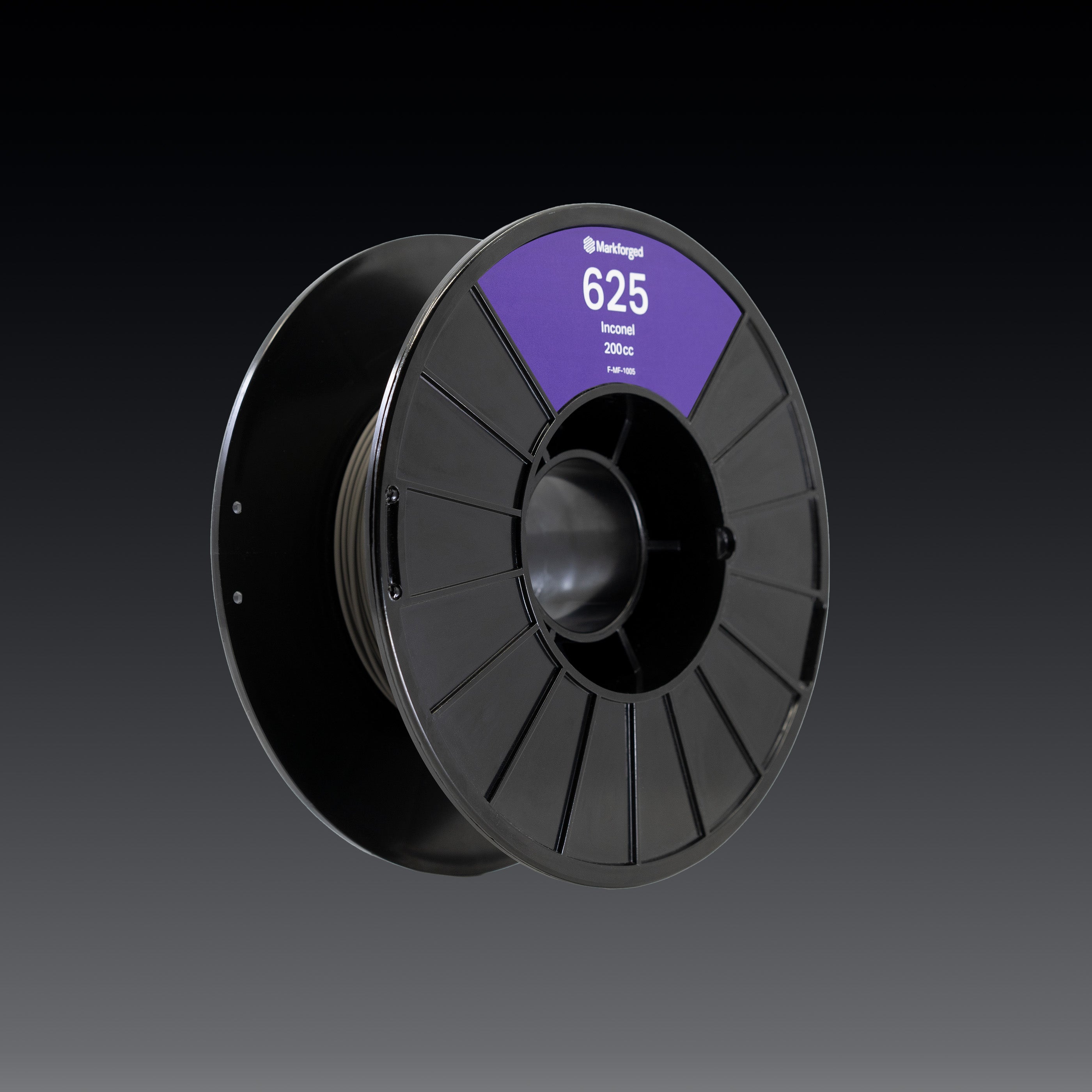

Inconel 625

Inconel 625 is a nickel-chromium based superalloy that is extremely resistant to corrosion and strong at high temperatures. It’s easy to print, enabling you to fabricate functional prototypes and end-use parts designed for harsh environments. Markforged Inconel 625 meets chemical requirements of ASTM B443 and maintains a UTS of 500 MPa at 600 ºC.

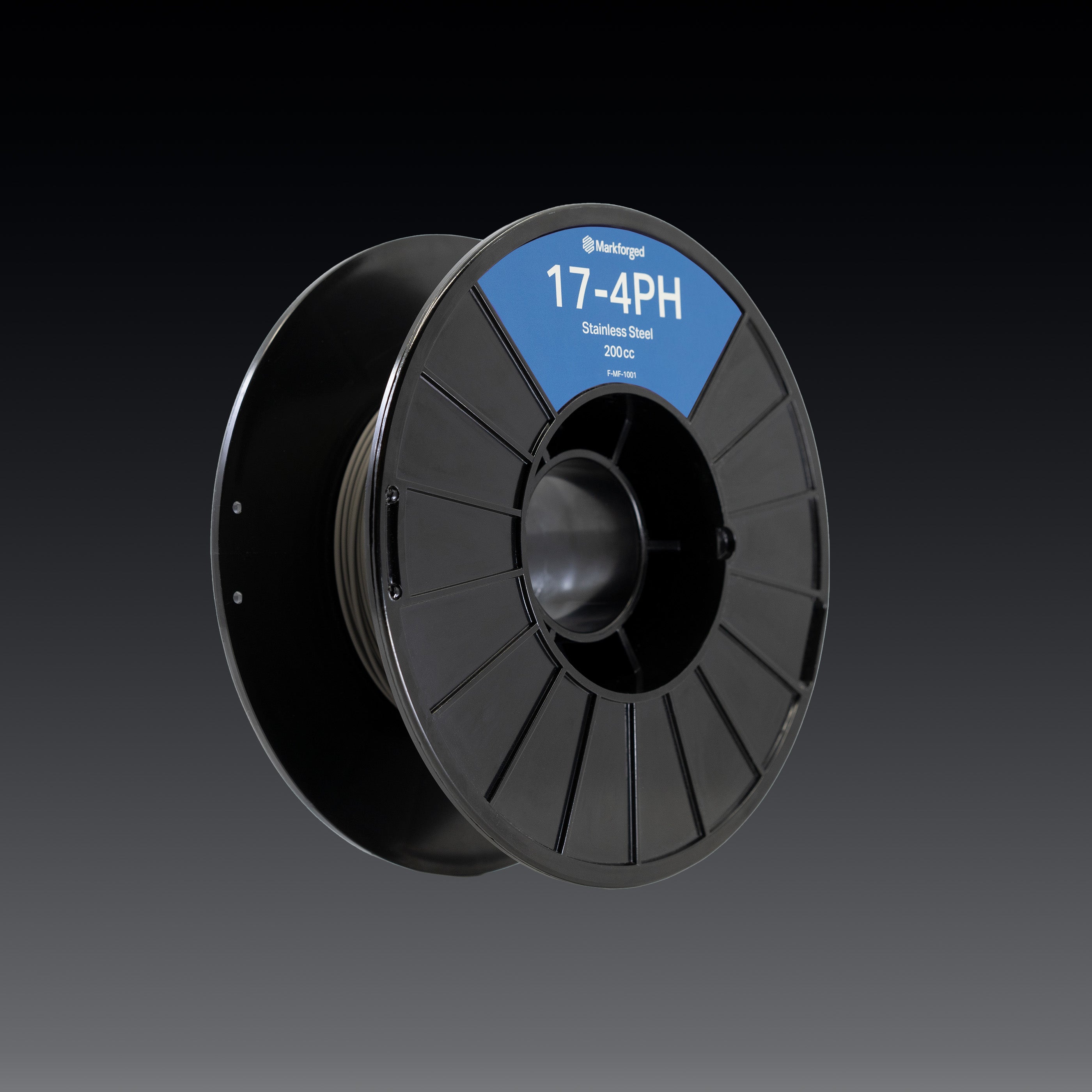

17-4PH Stainless Steel

17-4PH Stainless Steel is a multipurpose steel used for industrial applications. Heat-treatable to 36 HRC and possessing 95% wrought strength, Markforged 17-4PH enables you to print high-strength, robust metal parts for a wide variety of applications.

A2 and D2 Tool Steel

A2 and D2 are cold work tool steels defined by their extremely high hardness after heat treatment. A2 tool steel is often regarded as a “universal” cold work steel, offering a combination of good wear resistance and high toughness. D2 tool steel is harder and more wear-resistant, but less tough. Both can be used for cutting and forming tools, or other applications where high hardness are valued.

H13 Tool Steel

Harder than 17-4 PH Stainless Steel and capable of maintaining material properties at high temperatures, H13 tool steel is an extremely versatile material to work with. Markforged H13 can be heat treated to 45 HRC with a UTS of 1680 MPa, and is used by Markforged customers for tool bodies, brazing fixtures, and other parts where hardness or heat resistance are required.

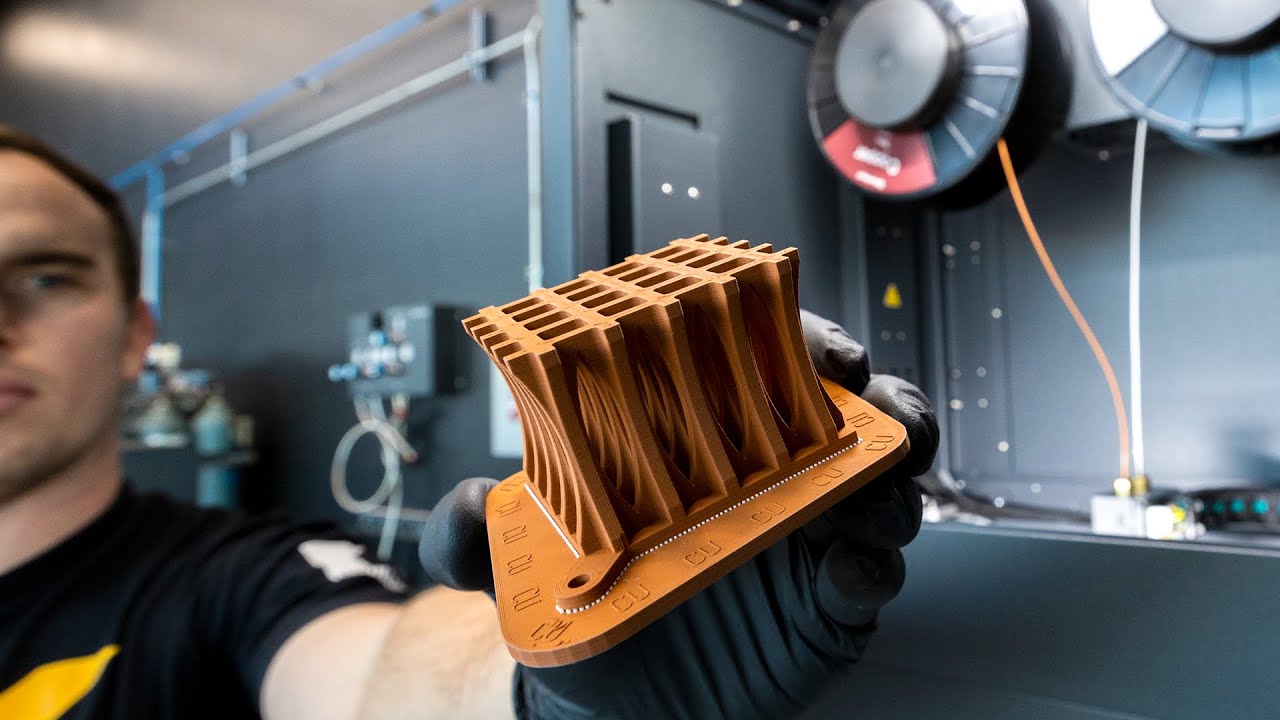

Copper

Pure copper conducts heat and electricity far better than traditional metals. Markforged Copper possesses better conductivity characteristics than alloyed copper that can be printed on DMLS machines. Unlike conventional fabrication processes which are extremely labor intensive and expensive, Markforged Copper is extremely simple to 3D print.

Simple and safe workflow designed for any business.

Why Choose Markforged?

Unlock Next-Level Precision and Innovation in Your Shop with 3D Printing.

Innovative Technologies

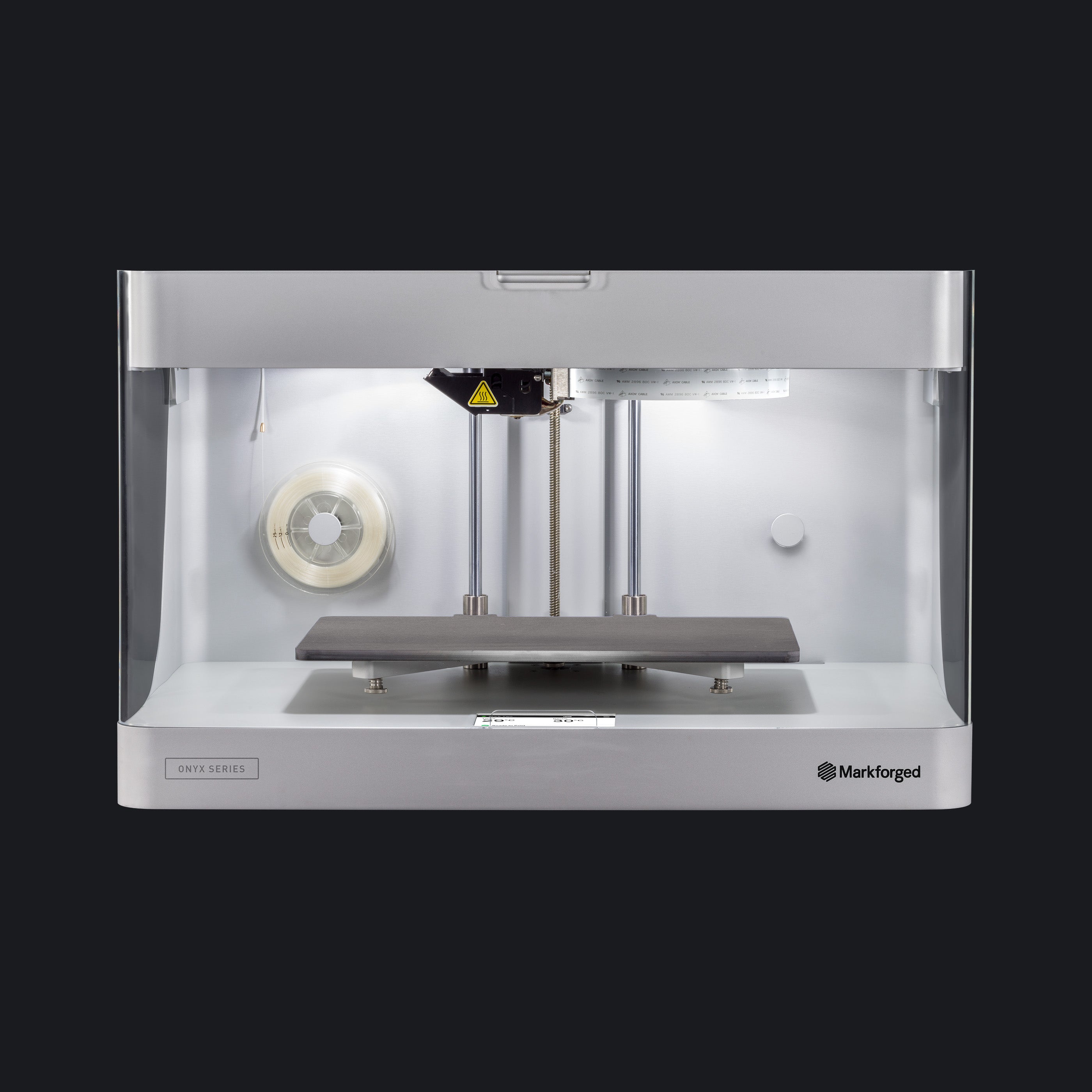

Markforged's innovations like carbon fiber reinforcement, integrated laser scanning quality control, and part simulation software evolved 3D printing from prototyping to the factory floor.

Strong, Precise Parts

Precision engineering printing hardware, advanced composite materials and carbon fiber reinforcement enable Markforged 3D printers to generate accurate, industrial-strength parts with beautiful surface finish time after time.

"Just Press Print" Simplicity

Markforged tightly integrates 3D printing hardware, materials, and intuitive software, making printing industrial-quality parts easy for non-experts on the shop floor.

Industrial Reliability

Markforged's industrial 3D printers are famed for their reliability, which is why over 5,000 manufacturing facilities across the world rely on Markforged to keep lines running and customers satisfied.

Scalability and Flexibility

The Digital Forge is designed to scale, catering to both small businesses and large enterprises. Whether you need one printer or a fleet, the platform scales to meet your production demands without the need for extensive retooling or setup changes.