Flat rate shipping applied at checkout for domestic orders. If actual rate varies, the final order amount will be adjusted.

For international orders, please contact us for a quote before placing an order.

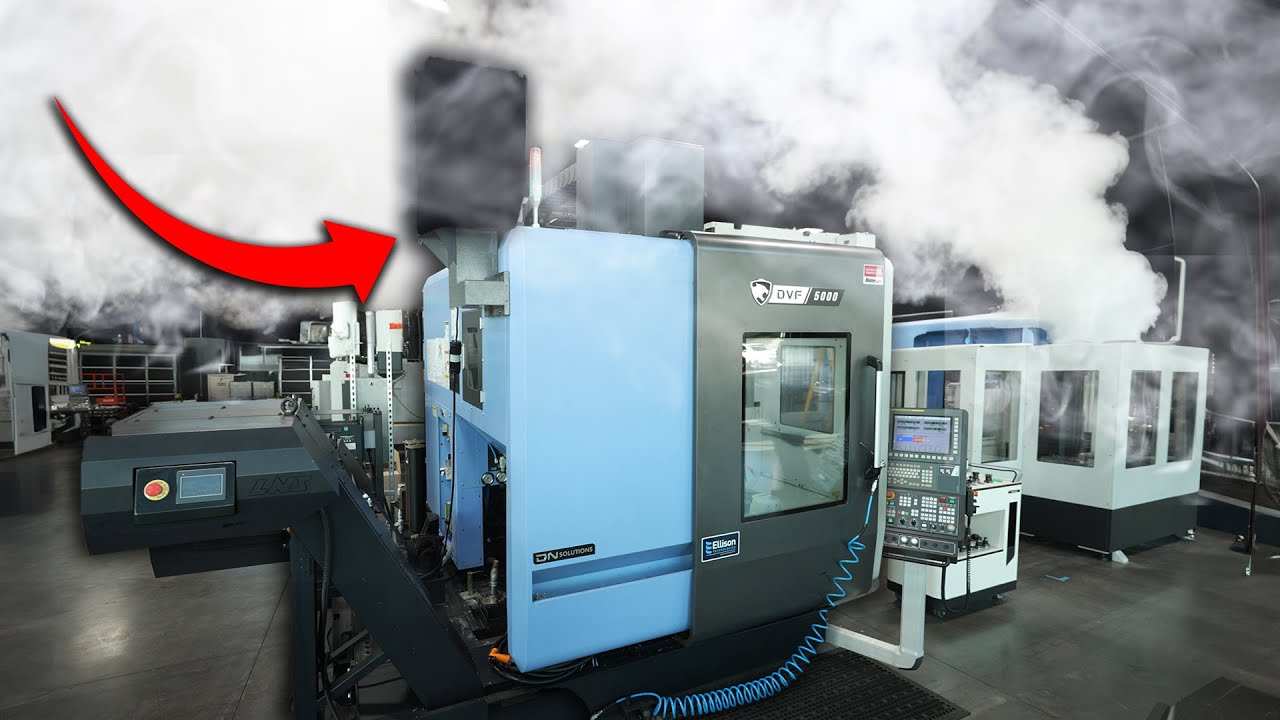

Mist-Fit MF-1950 Mist Collector

Product Info

Discover the Mist-Fit 1950: a high-performance, compact mist collector that leverages advanced fiber bed filtration technology for unmatched air purification. Offered at a competitive price, it's the ideal solution for managing high-pressure coolant and oil applications, ensuring fluids are efficiently returned to the CNC machine. Its 25" x 25" design allows for seamless machine integration, enhancing your factory's environment by eliminating mist, smoke, and fine particles. The system's modular build provides flexibility to incorporate additional features as needed.

Country of Origin: Canada

Tech Specs

- Coolant Filtration (Standard)

- Oil Filtration (Optional)

- Air Flow: 1900-2000 cfm

- Machine Tool Enclosure: Up to 2000 ft³

- Motor: 3 hp

- Voltage (Amps):

- 230/3/60 (6)

- 460/3/60 (3.3)

- Temperature (max) pH Limits: 125°F / 50°C, 5.8-9.8

- Weight: 270 lbs / 324 lbs with HEPA filter

- Dimensions: 25" x 25"

- Height:

- 36" base unit

- 44" with 95% HEPA filter

- 48" with 99.9% HEPA filter

- Inlet Connection: 12" ø

- Sound: 72 dB(A)

- Optional 4th Stage Filters:

- HEPA filter 95% @ 0.3 μm

- HEPA filter 99.9% @ 0.3 μm

Shipping & Returns

SHIPPING

- Orders are processed Monday–Friday and in the order they are received.

- Orders received after 5:00 PM CST will be processed the next business day.

- Orders are sent via UPS Ground, unless otherwise specified. Shipping times vary by brand:

- Aeroex: 7–10 days

- AMROK: 2–3 weeks

- Depureco: 2–3 weeks

- Dynamic 3D: 3–5 days

- EMCO: Varies

- Haimer: 3–5 days

- Kennametal: 1–3 days

- LNS: 3–5 days (filters); 1–2 weeks (mist collectors, spray cabins)

- Markforged: Varies

- Mitee-Bite: 3–5 days

- Mitutoyo: 7–14 days

- Orbital Computers: 5–9 days

- SCHUNK: 3–5 days

- Sodick: Varies

- SYIL: Varies

- TE-CO: 3–7 days

- TITANS of CNC: 1–2 days

- Tyrolit: 6–8 days

- Once your order has shipped, you will receive a confirmation email with tracking information.

- Orders placed outside of the United States may be subject to import and/or brokerage fees upon receipt of the package. Check with your package carrier and government for more information.

- Due to the global pandemic and its effects on the supply chain, there may be unforeseen delays in some shipments.

RESALE / RETURNS / REFUNDS / EXCHANGES

- Please review our RESALE / RETURN / REFUND / EXCHANGE Policies page for more information.

Installs Quickly

Time is money, and in manufacturing that could make or break your reputation. AEROEX‘s sleek, modular mist collectors give you the professional edge with its quick install design. Fits most machine tools with little to no modification required.

Easy to Use

AEROEX Mist Collectors are designed for hassle-free use, featuring easy-clean filters and straightforward operation to minimize downtime and keep your focus on the job. With their smart, user-friendly design, maintaining a clean shop environment is simpler than ever.

Clear the Air

Creating a safe and healthy work environment is crucial to the success of any machine shop. With AEROEX’s advanced multi-stage filtration technology, you're setting the standard for cleanliness and safety in your workspace, ensuring the wellbeing of your team and the durability of your machines.

Separation Stages

Multi-stage separation process effectively eliminates a wide range of airborne contaminants, ensuring not only the longevity and efficiency of machinery but also promoting a healthier workplace environment. By reducing exposure to harmful particulates, it enhances air quality and safety for all workspace occupants.

The innovative 1st stage Mechanical Element separates up to 90% of the oil mist and swarf, with smooth metal surfaces for quick fluid drainage back to the sump.

The 2nd stage Demister Element supports the 1st stage to ensure up to 95% of the mist and swarf are removed with washable filters.

The 3rd stage Fiber Bed mist filter is depth loading and captures small mist particles. With a filter rating of MERV 15, it can be used without a HEPA filter on most applications, with a typical life of 1-3 years.

HEPA Filter captures sub-micron mist, smoke, and bacteria. Efficiency is 95% @ 0.3 μm as standard, and optional 99.9% @ 0.3 μm, with a typical life of 2-4 years.

Pre-Filter Box is recommended for oil and heavy mist, extending filter life, particularly for Swiss screw machines.

Which Mist-Fit is Right for Your Machine Tool?

Compare Models

MF 550

| Airflow | 500–600 cfm |

|---|---|

| Enclosure | 250 ft³ |

| Motor | 0.75 hp |

| Max Temp | 125°F (50°C) |

| pH Limits | 5.8–9.8 |

| Weight | 65 lb (HEPA +10 lb) |

| Dimensions | 15 × 15 × 26 in |

| Inlet | 6″ ø |

| Sound | 66 dB(A) |

MF 560

| Airflow | 500–600 cfm |

|---|---|

| Enclosure | 250 ft³ |

| Motor | 0.75 hp |

| Max Temp | 125°F (50°C) |

| pH Limits | 5.8–9.8 |

| Weight | 96 lb (HEPA +26 lb) |

| Dimensions | 20 × 20 × 28 in |

| Inlet | 6″ ø |

| Sound | 66 dB(A) |

MF 1050

| Airflow | 900–1,100 cfm |

|---|---|

| Enclosure | 450 ft³ |

| Motor | 1.5 hp |

| Max Temp | 125°F (50°C) |

| pH Limits | 5.8–9.8 |

| Weight | 98 lb (HEPA +26 lb) |

| Dimensions | 20 × 20 × 28 in |

| Inlet | 8″ ø |

| Sound | 68 dB(A) |

MF 1950

| Airflow | 1,900–2,000 cfm |

|---|---|

| Enclosure | 2,000 ft³ |

| Motor | 3 hp |

| Max Temp | 125°F (50°C) |

| pH Limits | 5.8–9.8 |

| Weight | 270 lb (HEPA +54 lb) |

| Dimensions | 25 × 25 × 36 in |

| Inlet | 12″ ø |

| Sound | 72 dB(A) |

Machine Tool Enclosure Sizing Guide

When determining the sizing of mist collectors, several factors come into play. As a rule of thumb, we suggest multiplying the machine enclosure volume by a factor of 2-6 depending on the mist level, with a factor of 2 suitable for large machines of 1000 cubic feet and above.

| Condition | Multiplier (X) | Formula |

|---|---|---|

| Light Mist | 1 to 2 | L x W x H x Multiplier = Required CFM |

| Moderate Mist | 3 to 4 | L x W x H x Multiplier = Required CFM |

| Heavy Mist / Smoke | 4 to 6 | L x W x H x Multiplier = Required CFM |

Example: On a lathe with high-pressure coolant and an internal dimension of 5ft high X 6ft deep X 10ft long, the machine enclosure is 300 cubic feet—the calculation suggests an airflow requirement of approximately 900 CFM, when multiplied by a factor of 3.

Revolution is in the Air

Why Choose AEROEX?

Premium Filtration

AEROEX leads the mist collection industry with its cutting-edge multi-stage filtration technology, adept at capturing a broad spectrum of contaminants including coolant, oil, and swarf. With AEROEX's depth-loading fibre bed filters and optional HEPA stages, your workshop's air remains pristine, surpassing workplace air quality standards with ease. This filtration superiority ensures a focus on productivity in an environment protected by the best technology.

Affordable & Efficient

AEROEX stands out as the cost-effective choice in an industry where operational costs can escalate. Their mist collectors, known for unmatched durability and efficiency, offer significant savings over time, presenting a more economical ownership experience without compromising on performance.

Health & Safety

AEROEX mist collectors prioritize your team's well-being, engineered to meet the highest health and safety standards by capturing harmful airborne particles. These systems exemplify a commitment to safer work environments, effectively minimizing exposure to hazardous substances and ensuring peace of mind.

Environmental Excellence

AEROEX extends its commitment beyond the workshop, significantly enhancing the local and broader community's environment by reducing pollutant emissions. Their mist collectors align with and advance your facility's green initiatives, setting a new standard in sustainable operations.

Custom Solutions & Expert Support

AEROEX prides itself on delivering custom solutions that perfectly align with the unique demands of each workshop. Their expert team ensures that every mist collector integrates seamlessly into your operations, supported by customer service that truly sets AEROEX apart in the industry.