AL600P IGE Wire EDM

Financing options available.

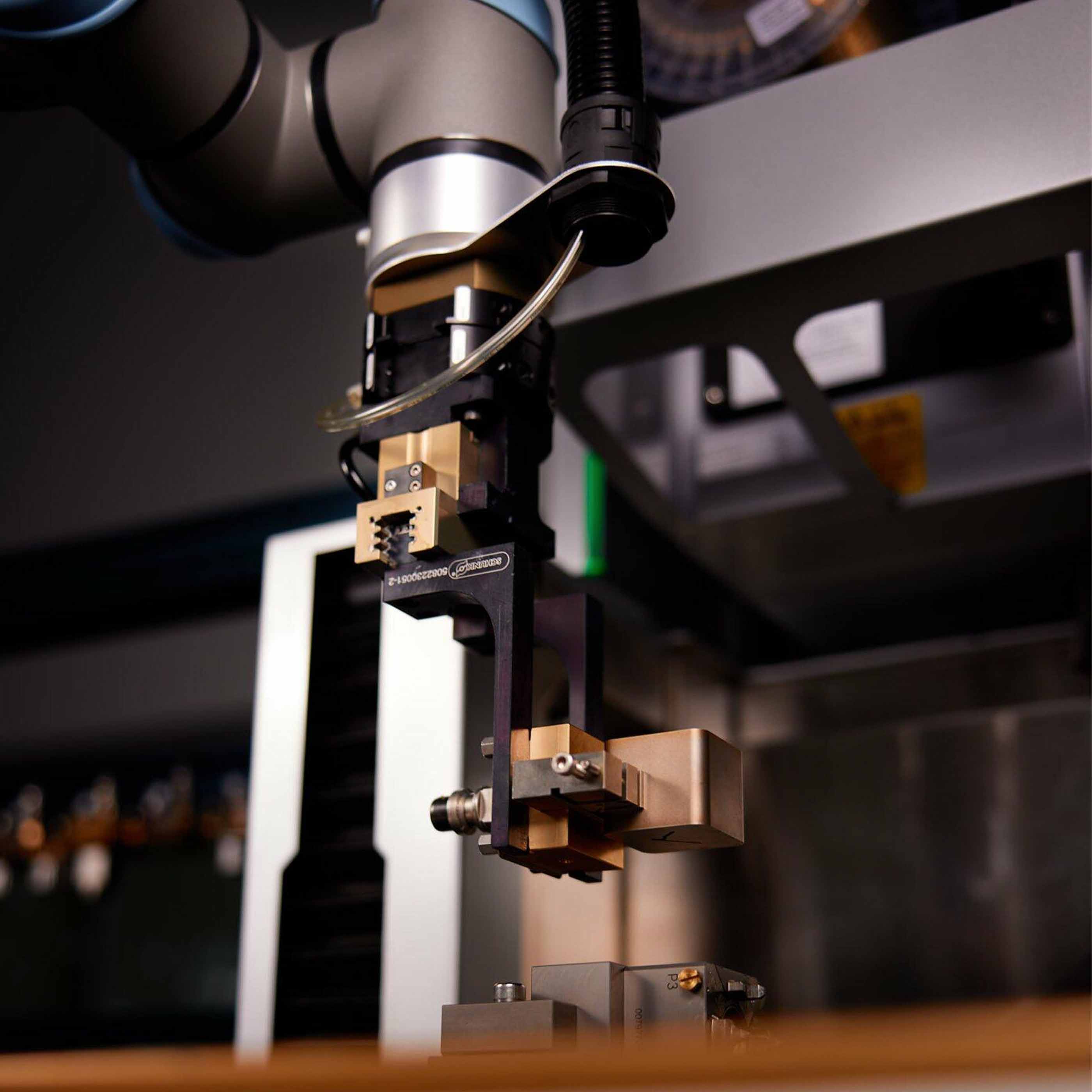

Precision and Innovation in Wire-Cut EDM

Exceptional Precision: The AL600P IGE is equipped with Sodick’s patented i Groove mechanism, offering unparalleled accuracy in wire rotation. This feature ensures consistent use of new wire surfaces during machining, significantly improving the surface finish and stability when working on thick plates.

Cutting-Edge Technology: With features like advanced “Step-cut” machining for shapes with varying thickness, and a maintenance-free linear motor drive, the AL600P IGE provides high-speed, precision machining with minimal wear, thanks to its non-contact system. The built-in thermal displacement correction ensures precise operation even in challenging temperature environments.

Country of Origin: Japan

WIRE EDM'S NEW GROOVE

Introducing the world’s first wire rotation system, the 'i Groove.' This game-changer ensures super precise cuts by minimizing pitch error, making it perfect for progressive press dies. Backed by our own advanced tech, it delivers top-notch performance every time.

Tech Specifications

41.34" x 27.95" / 1050mm x 710mm

23.62" / 600mm

23.62" / 600mm

15.75" / 400mm

13.78" / 350mm

5.91" x 5.91" / 150mm x 150mm

±25° (Plate Thickness 5.12" / 130mm)

31.50" x 22.44" x 13.39" (during flushing machining) / 800mm x 570mm x 340mm

31.50" x 22.44" x 11.02" (during submerged machining) / 800mm x 570mm x 280mm

2204.62 lbs / 1000kg

Ø0.002" – Ø0.012" / Ø0.05mm – Ø0.30mm

3-23N (remains the same)

16.54 in/sec / 420mm/sec

39.17" / 995mm

101.38" x 116.54" x 92.32" / 2575mm x 2960mm x 2345mm

10,141.26 lbs / 4600kg

Why Choose Sodick?

Pushing the Boundaries of Wire EDM.

Precision Meets Speed

Sodick machines combine unparalleled precision with fast cutting speeds, allowing machinists to achieve high-quality results without sacrificing efficiency, even on the most demanding jobs.

Tailored Machining Solutions

Sodick offers a wide range of machines that cater to industries such as aerospace, automotive, and mold-making, with customizable options to suit both high-precision and high-speed production requirements.

High Reliability, Low Maintenance

Sodick’s machines are engineered with maintenance-free linear motors, minimizing downtime and ensuring that your shop runs smoothly with fewer interruptions for repairs or adjustments.

Commitment to Quality

With over 40 years of industry experience, Sodick’s vertically integrated production process ensures the highest level of quality control at every step—from R&D to final machine assembly—giving machinists confidence in their investment.

Global Expertise, Local Support

Sodick has a strong global presence, offering industry-leading service and support, backed by expert teams to provide local assistance and training wherever your shop is located.