MX-330 PC10 5-Axis Vertical Machining Center

Financing options available.

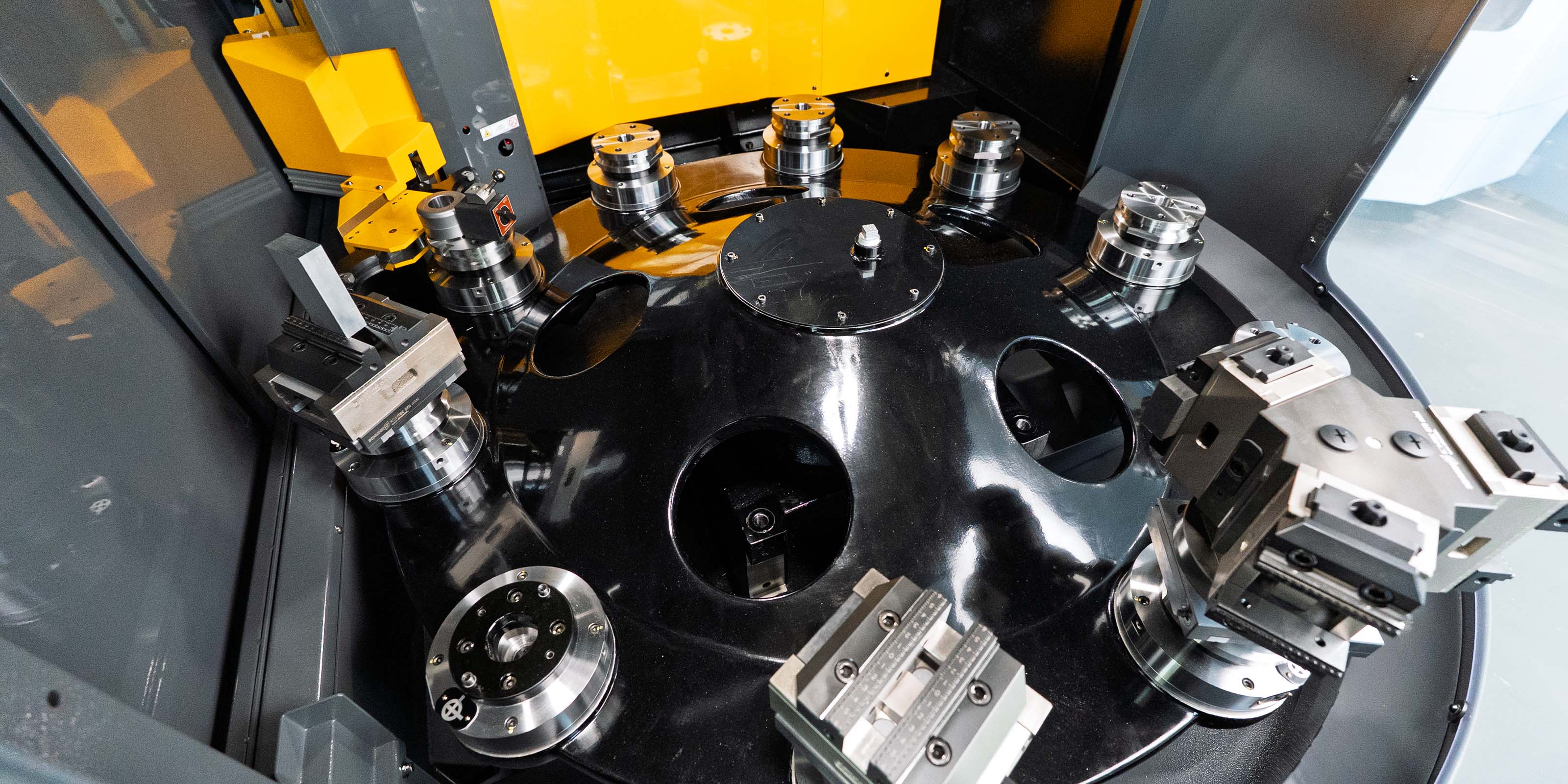

Compact 5-Axis Machining Center with PC10 Pallet Changer

The MX-330 brings 5-axis machining to shops of all sizes with a compact footprint and outstanding versatility. Designed for accuracy and repeatability, it enables single-setup machining of complex parts across aerospace, medical, and precision industries. Its rigid design and advanced control system make it a smart fit for both production and prototyping environments.

With the PC10 pallet changer system, shops gain true lights-out capability — continuous machining across multiple setups without operator intervention. Combined with a high-speed spindle and automatic tool changer, the MX-330 ensures maximum spindle uptime, efficiency, and productivity. This platform is a go-to solution for shops looking to expand their 5-axis capacity with automation-ready reliability.

Available in multiple configurations.

Country of Origin: Japan

Product Info

The Matsuura MX-330 with the PC10 pallet changer takes 5-axis machining to the next level. Designed for lights-out production, the PC10 system allows continuous, unattended machining across multiple setups, maximizing spindle uptime and throughput. Combined with the MX-330’s high-speed spindle and generous tool capacity, this platform delivers unmatched efficiency for both high-mix, low-volume work and long production runs.

Technical Data

| Specification | Details |

|---|---|

| Standout Features | Compact design, large tool magazine option, automation-ready |

| Additional Axis | B-axis tilt ±125°, C-axis continuous 360° |

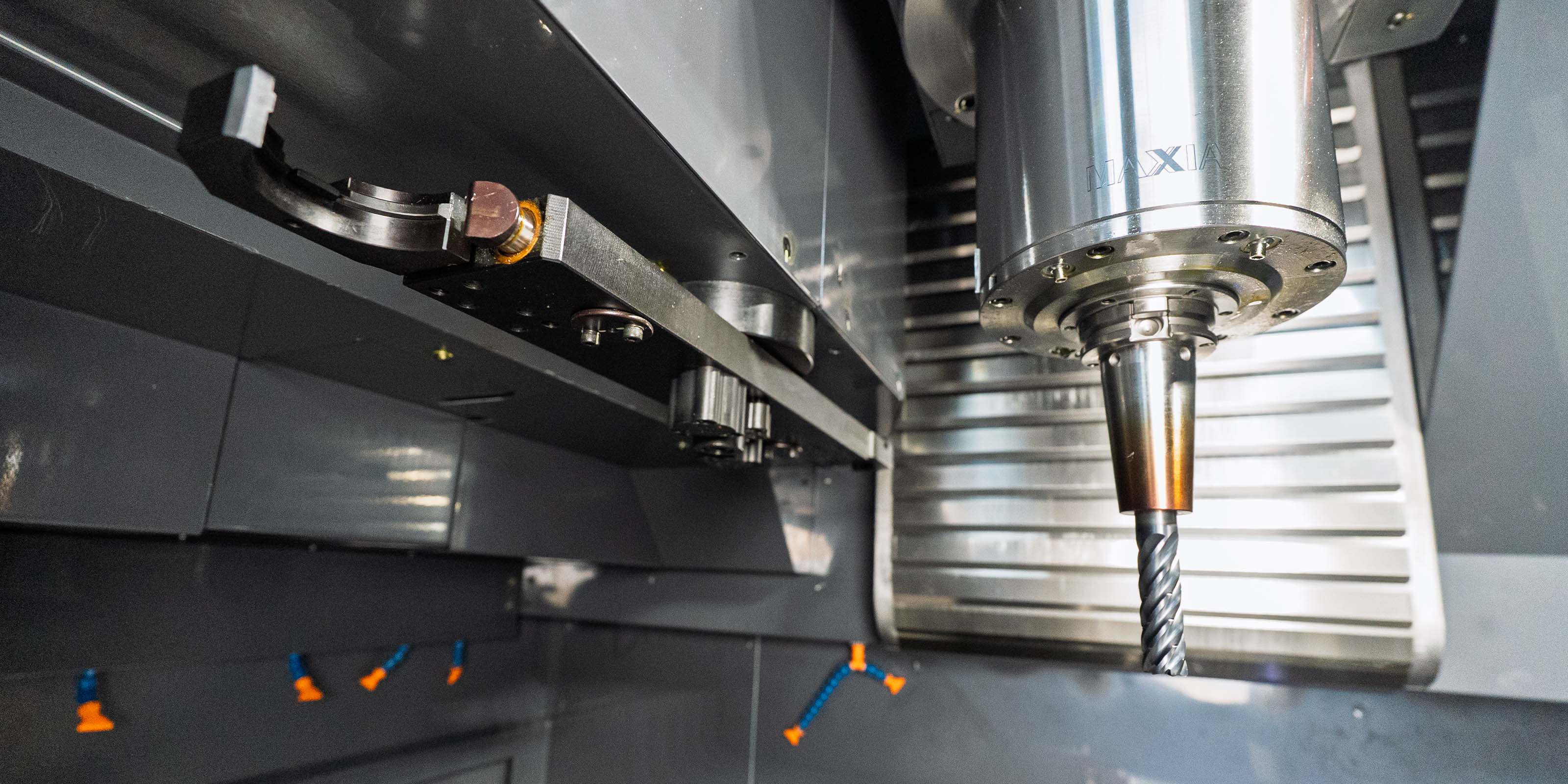

| Spindle Speed | 15,000 rpm |

| Spindle Power | 20 hp (15 kW) |

| Tool Taper | BT40 / HSK-A63 |

| Table Size | 13.8" diameter (350 mm) |

| Max Workpiece Weight | 176 lbs (80 kg) |

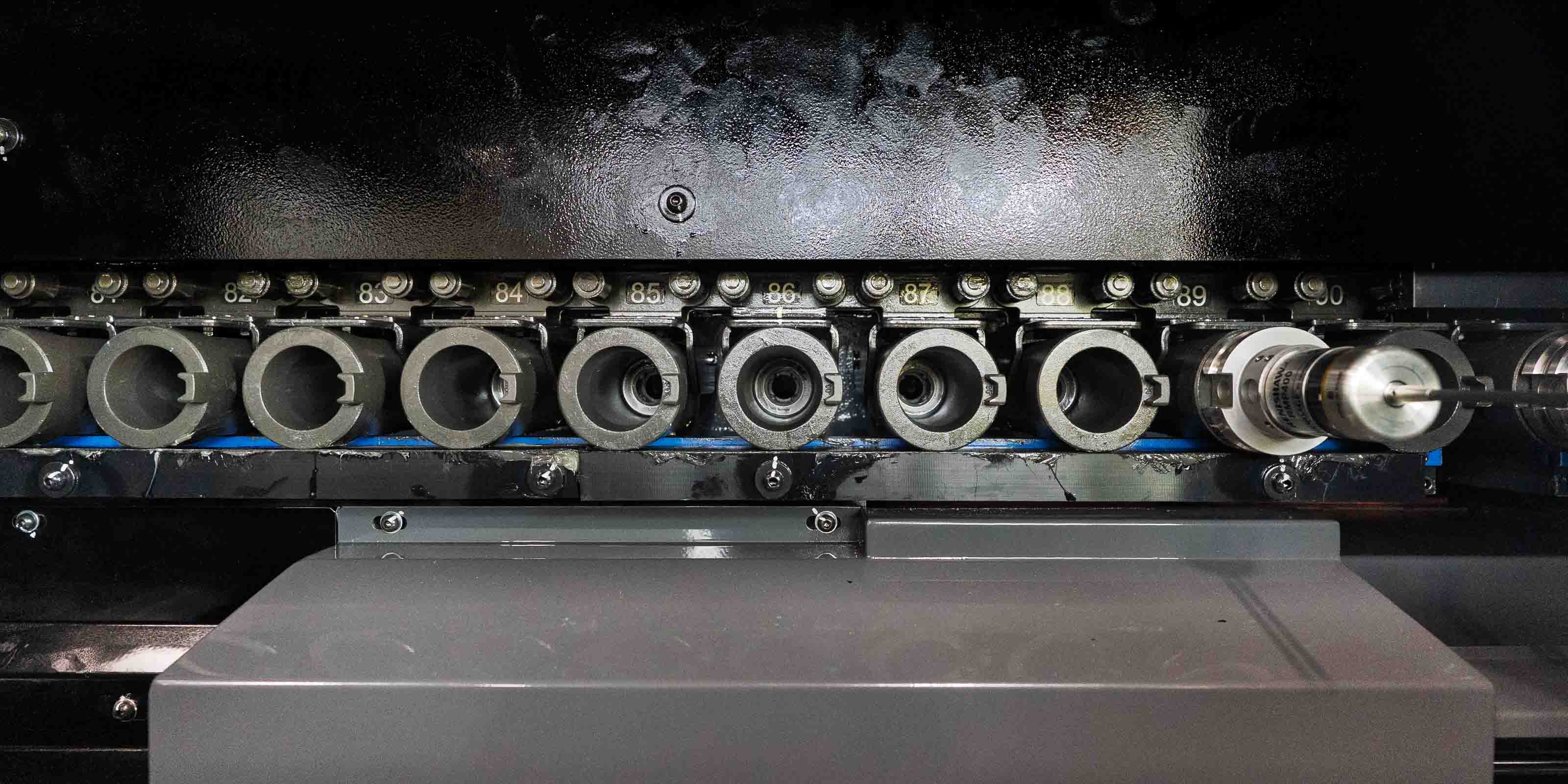

| Tool Changer Capacity | 30 tools (optional up to 90) |

| Control | FANUC 31i-MB Plus |

| Automation Capability | PC10 pallet changer system, full automation integration |

Compact Power, Big Results

The MX-330’s high-speed spindle delivers up to 15,000 rpm with 20 hp (15 kW) of power, handling tough materials and fine surface finishes with ease. Its ±125° B-axis and 360° C-axis provide true 5-axis flexibility, while tool capacity up to 90 tools supports long production runs. A compact footprint makes it perfect for small shops wanting to expand into 5-axis machining without sacrificing floor space.

Compact 5-Axis Design

Tech Specifications

15,000 rpm

20 hp (15 kW)

BT40 / HSK-A63

30 tools (optional up to 90)

FANUC 31i-MB Plus

13.8" diameter (350 mm)

176 lbs (80 kg)

B-axis tilt ±125°, C-axis continuous 360°

Optional pallet system, automation integration

Compact design, large tool magazine option, automation-ready

Why Choose Matsuura?

Innovation that Drives Precision

Japanese Craftsmanship

Built in Japan with precision engineering and rigorous quality control.

Automation Leadership

Industry pioneer in multi-pallet and lights-out production systems.

Trusted Reliability

Decades of proven uptime in aerospace, medical, and precision machining.

Cutting-Edge Technology

Integration of advanced spindles, controls, and monitoring systems.

Global Support Network

Strong distributor and service network ensures long-term partnership.