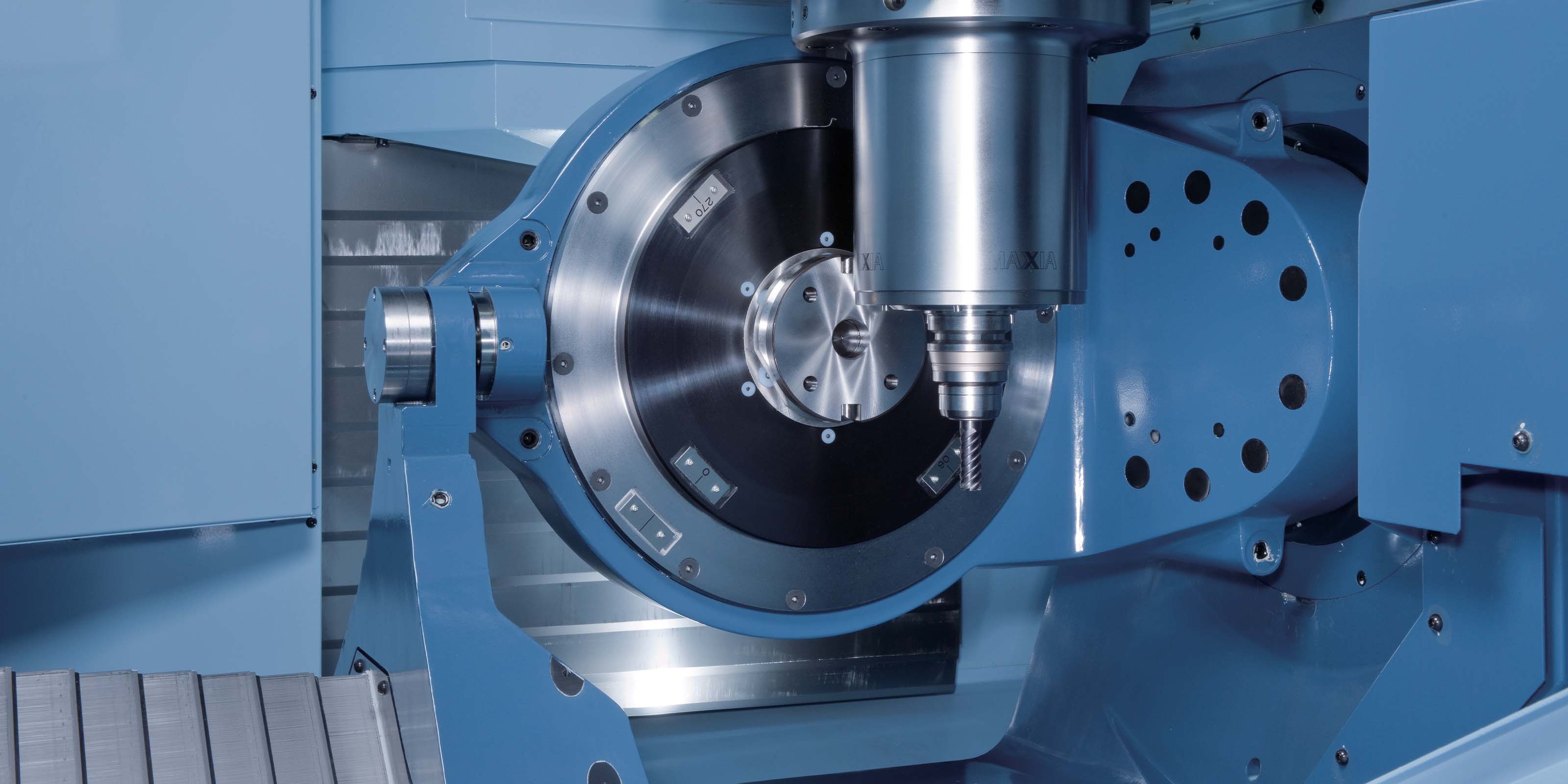

MAM72-35V 5-Axis Production Machining Center

Financing options available.

Lights-Out 5-Axis Production Center

The MAM72-35V is built for continuous, unattended 5-axis machining. With ±120° B-axis tilt and a full 360° C-axis, it tackles complex parts in one setup while maintaining tight tolerances and consistent surface finish. A high-speed spindle and fast tool changes keep cycle times short and throughput high—ideal for aerospace, medical, and precision job shops.

Standard controls include FANUC 31i-MB Plus or Heidenhain TNC 640, giving shops proven reliability and powerful 5-axis capability. Add pallets and automation to run lights-out and keep chips flying around the clock.

Available in multiple configurations.

Country of Origin: Japan

Product Info

The MAM72-35V delivers true 5-axis simultaneous machining with a rigid platform, fast tool changes, and automation-ready design. Its high-speed spindle and HSK-A63 interface drive aggressive metal removal on aluminum through stainless and superalloys, while the rotary table’s wide tilt range completes complex geometries in one hit. With FANUC or Heidenhain control and proven long-run reliability, it’s a production workhorse for shops that measure output in parts per shift—not hours per setup.

Technical Data

| Specification | Details |

|---|---|

| Travel (X / Y / Z) | 25.6" / 28.7" / 23.6" (650 / 730 / 600 mm) |

| 5th-Axis Type | Tilting rotary table (B / C) |

| B-Axis Range | ±120° |

| C-Axis Rotation | 360° continuous |

| Table Size | Ø25.6" (Ø650 mm) |

| Max Workpiece Weight | 882 lbs (400 kg) |

| Spindle Speed | 15,000 rpm |

| Spindle Power | 35 hp (26 kW) |

| Tool Taper | HSK-A63 |

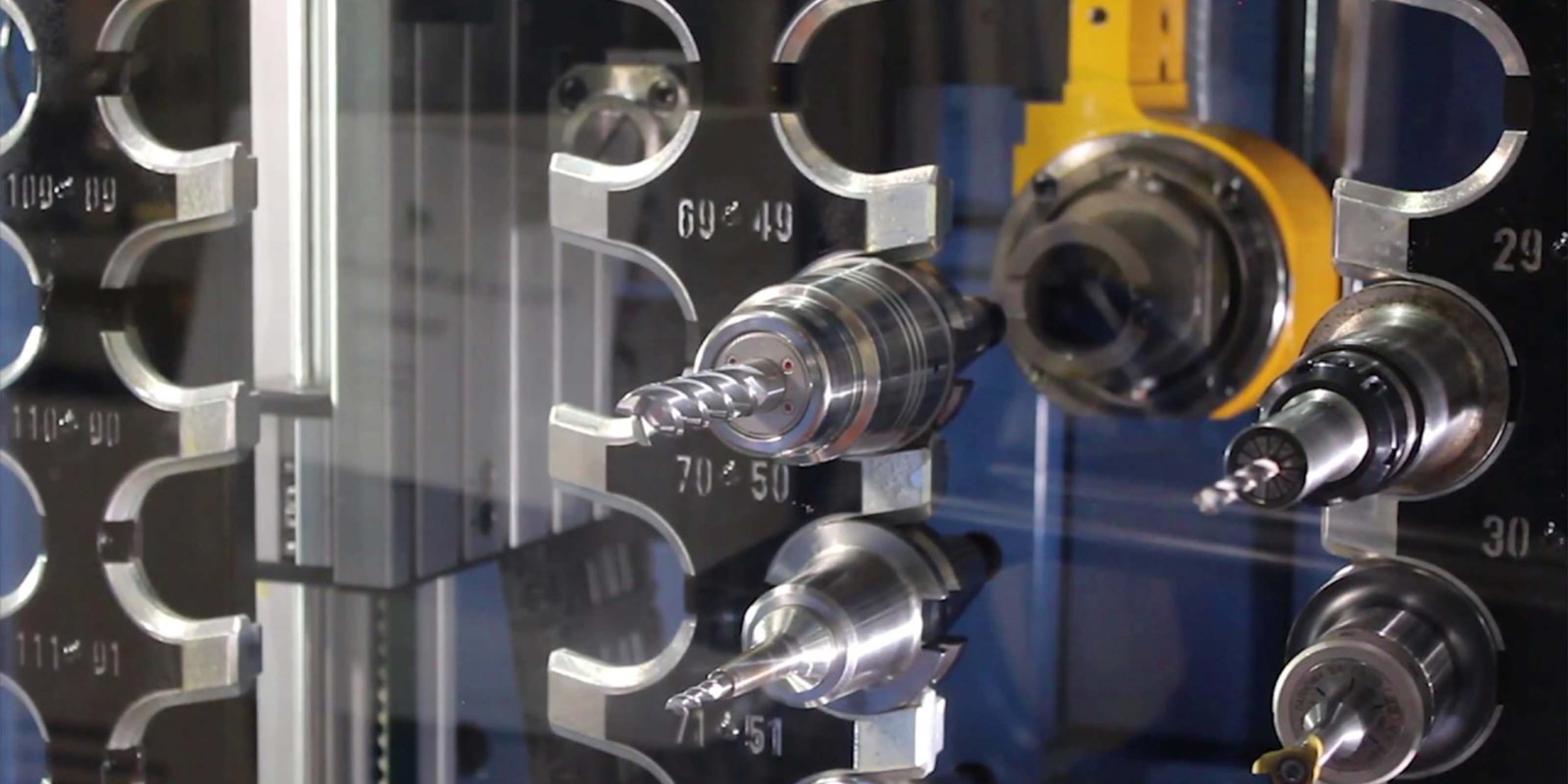

| Tool Magazine Capacity | 40 tools |

| Control | FANUC 31i-MB Plus / Heidenhain TNC 640 |

Unstoppable 5-Axis Productivity

The high-speed spindle reaches 15,000 rpm with 35 hp (26 kW) of power, delivering both rapid material removal and fine surface finishes. With B-axis tilt of ±120° and full 360° C-axis rotation, the MAM72-35V excels at complex 5-sided machining in a single setup. With a tool capacity up to 40 tools, this machine tool ensures uninterrupted cycles, while automation options support long, lights-out production runs.

Tech Specifications

15,000 rpm

35 hp (26 kW)

HSK-A63

40 tools (optional up to 530)

FANUC 31i-MB Plus / Heidenhain TNC 640

25.6" diameter (650 mm)

882 lbs (400 kg)

B-axis tilt ±120°, C-axis continuous 360°

Multi-pallet system, lights-out machining

5-axis simultaneous machining, automation-ready, large tool magazine

Why Choose Matsuura?

Innovation that Drives Precision

Japanese Craftsmanship

Built in Japan with precision engineering and rigorous quality control.

Automation Leadership

Industry pioneer in multi-pallet and lights-out production systems.

Trusted Reliability

Decades of proven uptime in aerospace, medical, and precision machining.

Cutting-Edge Technology

Integration of advanced spindles, controls, and monitoring systems.

Global Support Network

Strong distributor and service network ensures long-term partnership.