LUMEX-Avance-25 Hybrid Metal 3D Printer

Financing options available.

Hybrid Additive and Subtractive Machining Center

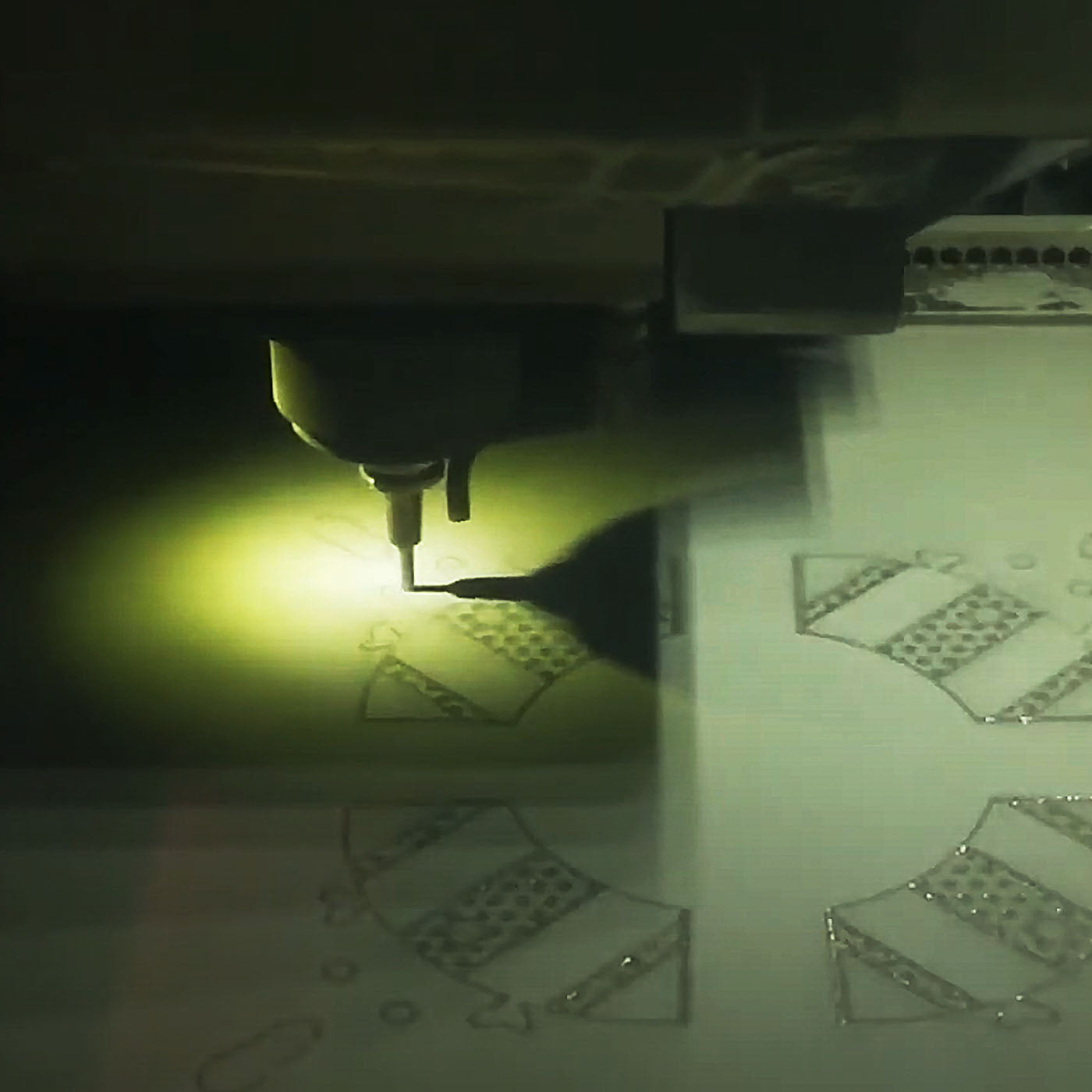

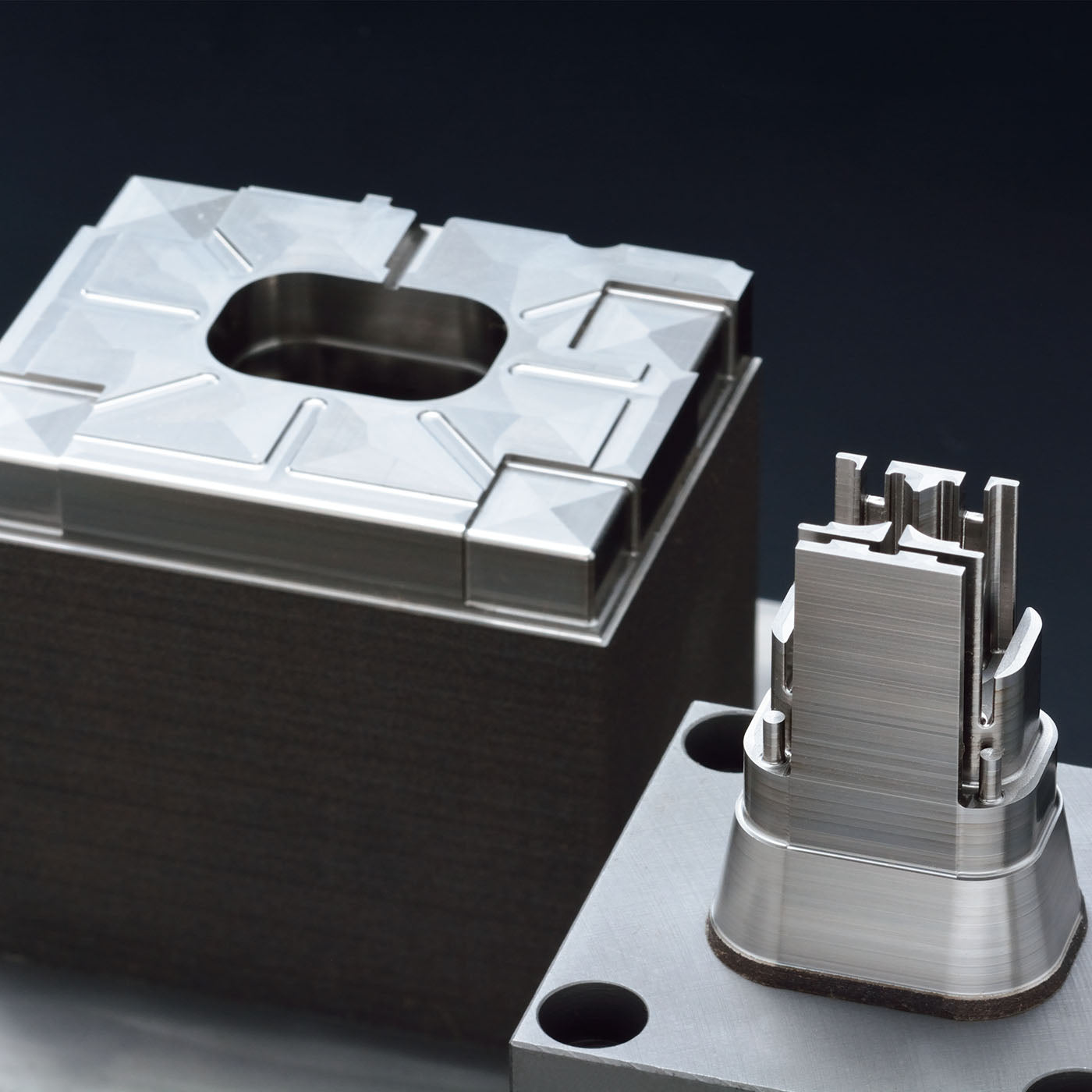

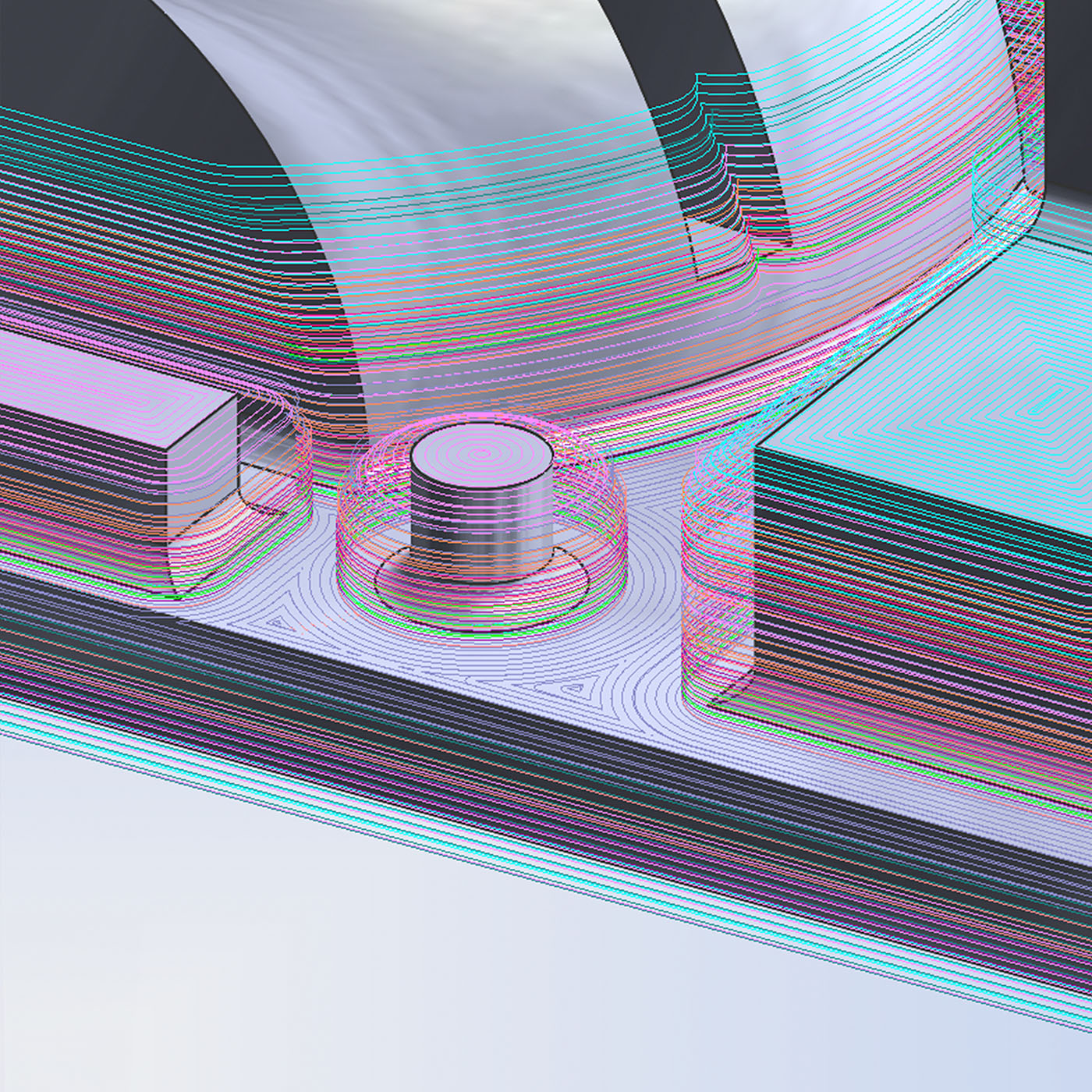

The LUMEX Avance-25 is a breakthrough in metal additive manufacturing, combining powder-bed laser sintering with high-speed milling. This hybrid process enables the creation of highly complex parts with internal channels, fine details, and unmatched accuracy—features impossible with traditional machining alone.

Built for aerospace, medical, and mold-making industries, the LUMEX Avance-25 streamlines the production of conformal cooling molds and intricate components. By integrating 3D printing and machining in one platform, it reduces setups, eliminates secondary operations, and saves time and cost for advanced manufacturers.

Country of Origin: Japan

Product Info

The Matsuura LUMEX Avance-25 is the world’s first hybrid metal 3D printer and milling machine. Designed for precision additive and subtractive processes in one platform, it gives manufacturers the ability to produce molds, medical implants, and aerospace components with internal structures and fine detail. Combining laser sintering and high-speed milling, the LUMEX Avance-25 cuts lead times and opens new design possibilities for advanced manufacturing.

Technical Data

| Specification | Details |

|---|---|

| Standout Features | Hybrid additive + subtractive machining, internal channel capability |

| Build Size | 9.8" × 9.8" × 15.7" (250 × 250 × 400 mm) |

| Laser Specs | 400 W fiber laser |

| Spindle Speed | 45,000 rpm milling spindle |

| Spindle Power | 2.7 hp (2 kW) |

| Tool Taper | HSK-E32 |

| Max Workpiece Weight | 220 lbs (100 kg) |

| Tool Changer Capacity | 20 tools |

| Control | FANUC 31i-B5 AM |

| Automation Capability | Supports integrated monitoring, automation-ready |

Hybrid Manufacturing. Redefined.

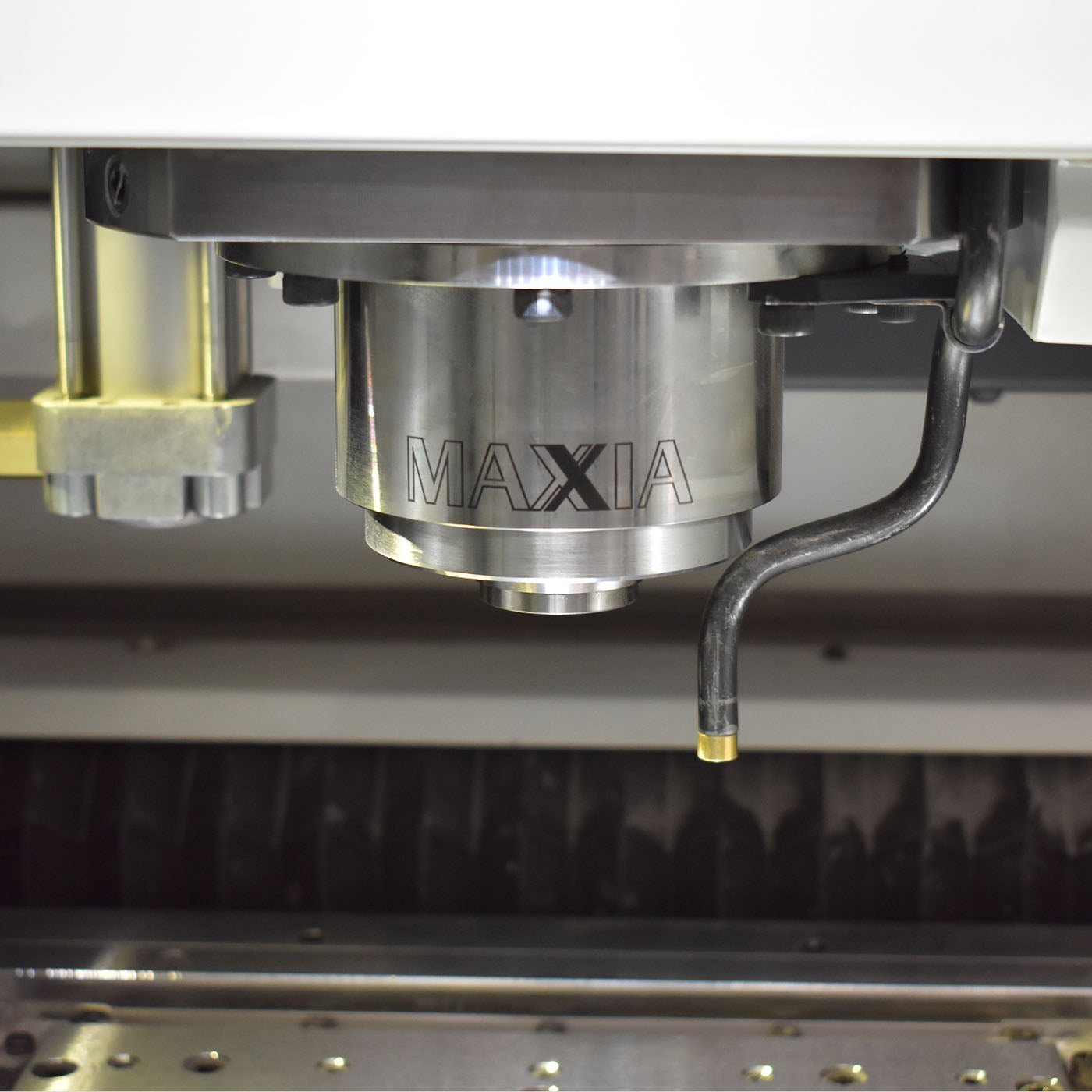

The LUMEX Avance-25 combines a 400 W fiber laser with a 45,000 rpm spindle, enabling simultaneous additive and subtractive manufacturing. Its hybrid capability produces intricate geometries, internal cooling channels, and high-precision surfaces in a single setup. By merging 3D printing with milling, it reduces lead times, eliminates secondary operations, and expands design freedom.

Tech Specifications

500 W

FANUC 31i-B5 AM

20 tools

Automatic and manual handling options

9.8" × 9.8" × 15.7" (250 × 250 × 400 mm)

305 in³ (5,000,000 mm³)

0.002" – 0.004" (50 – 100 µm)

220 lbs (100 kg)

Supports integrated monitoring, automation-ready

Hybrid additive + subtractive machining, internal channel capability

Why Choose Matsuura?

Innovation that Drives Precision

Japanese Craftsmanship

Built in Japan with precision engineering and rigorous quality control.

Automation Leadership

Industry pioneer in multi-pallet and lights-out production systems.

Trusted Reliability

Decades of proven uptime in aerospace, medical, and precision machining.

Cutting-Edge Technology

Integration of advanced spindles, controls, and monitoring systems.

Global Support Network

Strong distributor and service network ensures long-term partnership.