EMCO UMILL 630 Universal 5-Axis Milling Center

Financing options available.

Compact Universal Machining Center

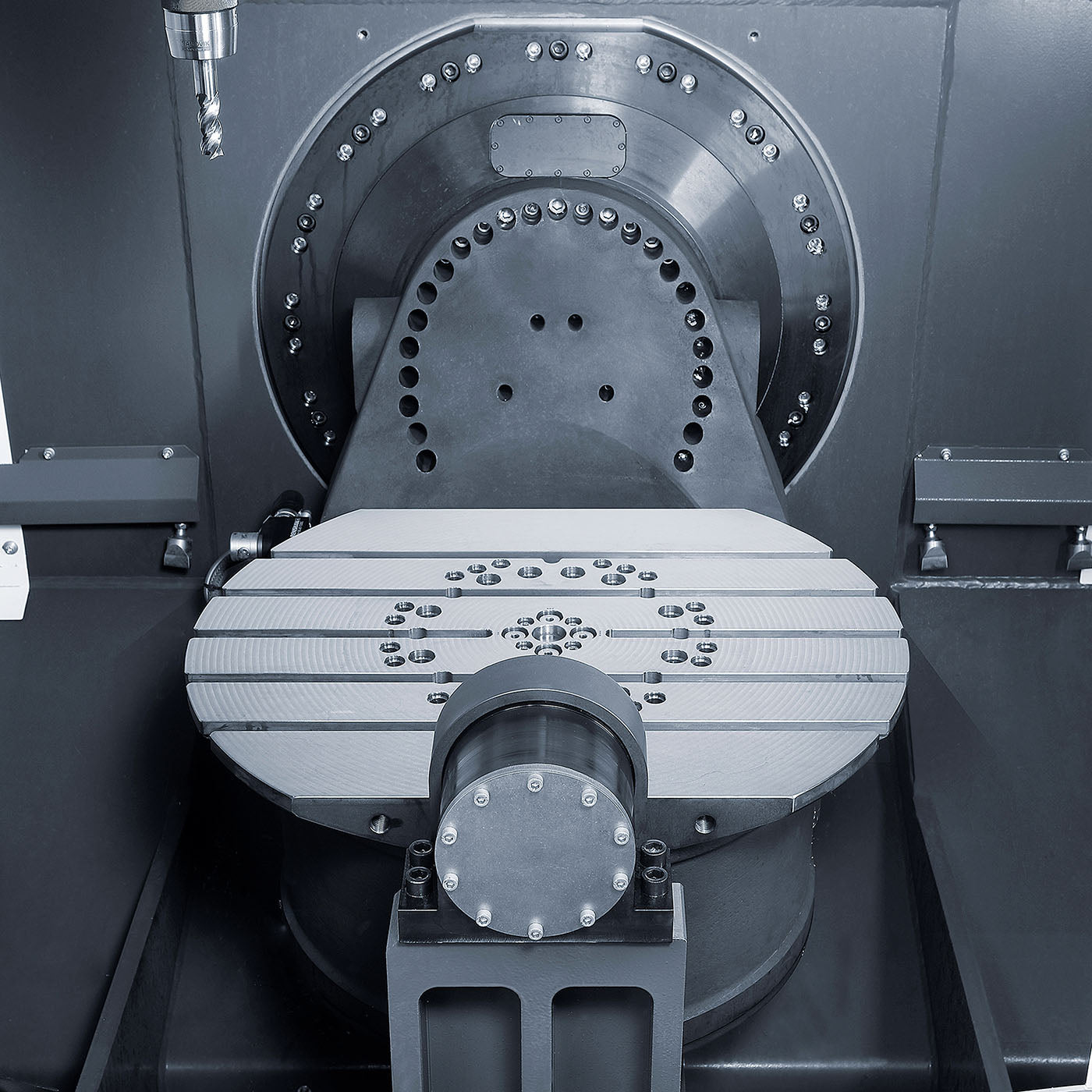

The EMCO UMILL 630 is a 5-axis universal machining center designed for precision and flexibility. A solid swivel-rotary table, direct drives in X, Y, and Z, and linear scales as standard deliver the rigidity and accuracy required for complex machining work.

The large clamping area of 24.8 × 19.7 in (630 × 500 mm) supports workpieces up to 661 lb (300 kg). The B-axis swivels ±100 degrees and the C-axis rotates continuously, allowing smooth multi-axis contouring. Equipped with Siemens Sinumerik ONE or Heidenhain TNC 640 controls and EMCONNECT digital integration, the UMILL 630 is built for automation-ready production environments.

Country of Origin: Austria

Customize Your CNC

BEYOND STANDARD

The EMCO UMILL 630 delivers high-precision 5-axis simultaneous machining with a swivel-rotary table and direct drives for rock-solid rigidity. Built to power through aerospace alloys, titanium, and heat-resistant superalloys, it maintains accuracy while keeping cycle times short. With advanced automation, short idle times, and a compact footprint, it’s designed for high-performance machining. Cutting-edge control options from Siemens and Heidenhain, plus EMCONNECT for digital workflow optimization, make it automation-ready for demanding industries like aerospace, medical, and energy.

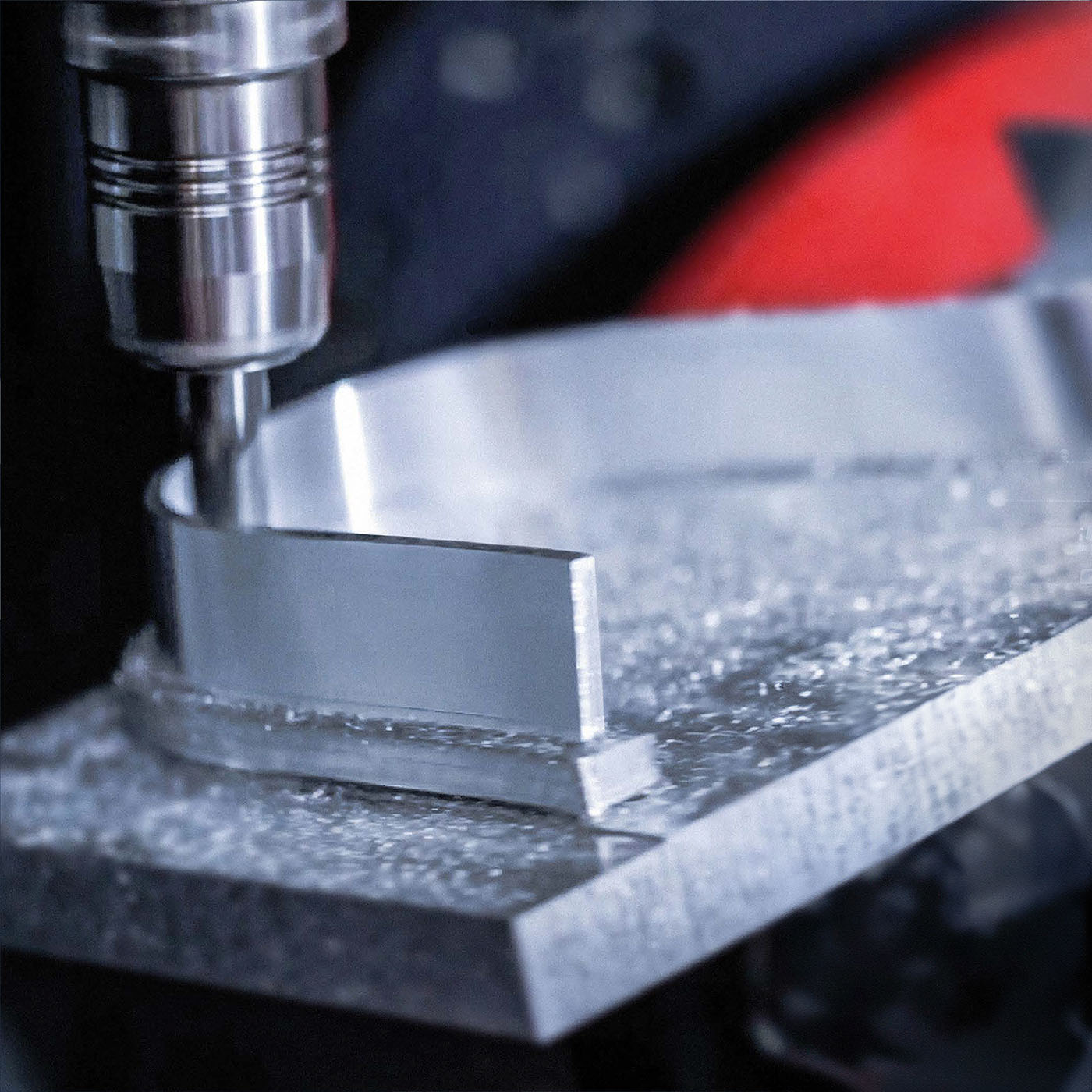

SPEED MEETS PRECISION

The HSK-A63 motor spindle delivers high-speed precision with speeds up to 24,000 rpm and 110 Nm of torque, ensuring exceptional performance across a wide range of materials. Direct-drive technology enhances rigidity and accuracy, making the UMILL 630 ideal for complex machining applications requiring both power and precision.

Tech Specifications

19.7" + 2" / 18.1" / 17.7" (500 + 50 mm / 460 mm / 450 mm)

1,969 in/min (50 m/min)

19.7 ft/s² (6 m/s²)

0.0004" (10 µm) / 0.00016" (4 µm)

±100° / 50 rpm

0 - 360° / 100 rpm

±5 arcsec

Swivel-Rotary Table

Why Choose EMCO?

Precision engineered. Performance delivered.

Innovative Machining Solutions

EMCO develops flexible, high-performance machining systems built for industries like aerospace, automotive, and general manufacturing.

Built by EMCO

Every EMCO machine is designed and manufactured in-house, ensuring the highest level of quality, precision, and technological innovation.

Engineered for 24/7 Production

Designed for durability and efficiency, EMCO machines deliver stable performance in demanding, multi-shift environments.

Comprehensive Lifecycle Support

From installation to maintenance and upgrades, EMCO provides full-service support to maximize uptime and productivity.

Global Reach, Local Expertise

With worldwide manufacturing and service hubs, EMCO delivers reliable solutions and expert support wherever you operate.