EMCO MMV 3200 Machining Center

Financing options available.

Massive Capacity. Maximum Control.

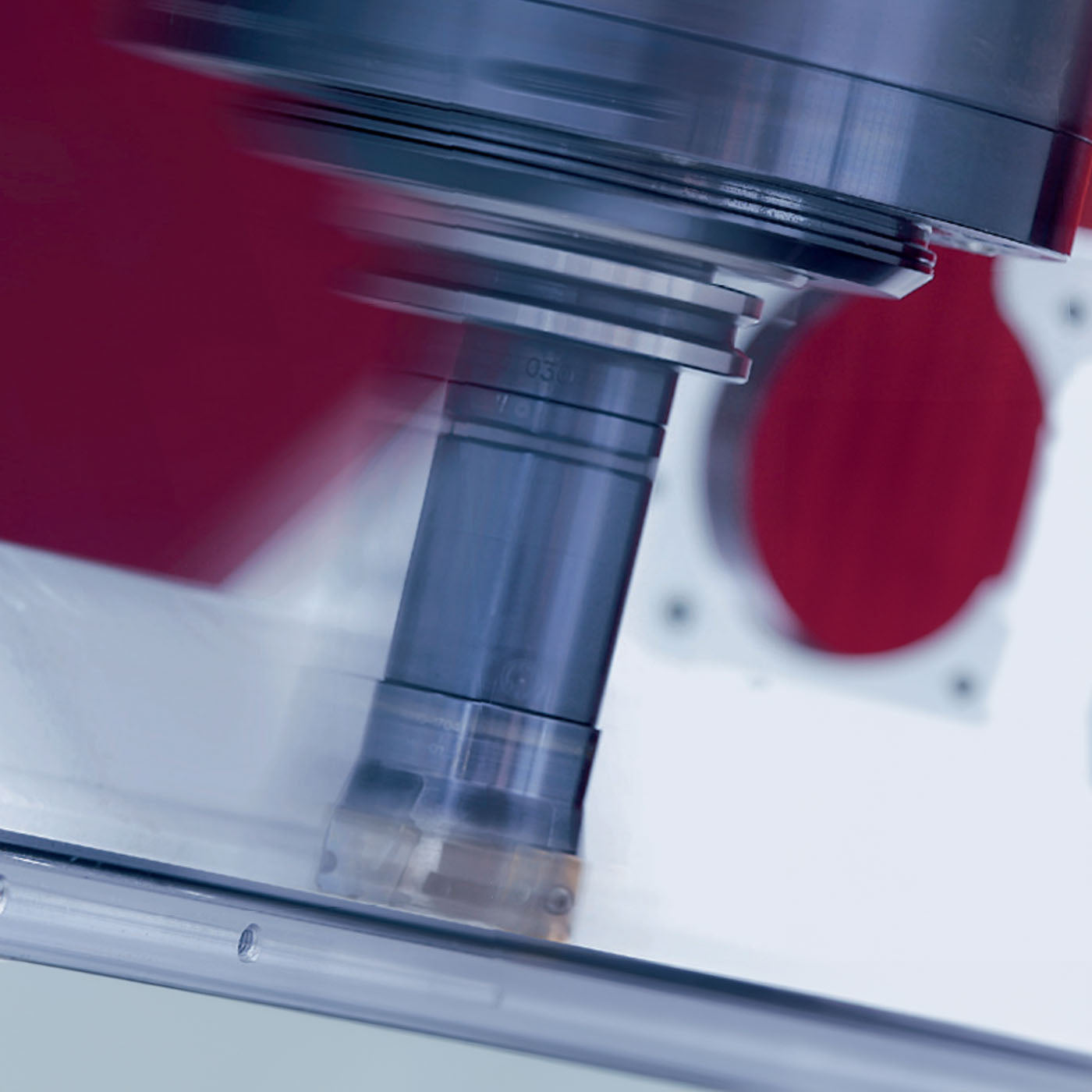

The EMCO MMV 3200 is built for large-part production machining where rigidity and travel matter. With 126 in of X-axis travel (3,200 mm), it handles oversized aerospace, power generation, and defense components with confidence. A high-power inline motor spindle delivers up to 12,000 rpm and 59 kW, providing strong cutting performance and efficient chip evacuation.

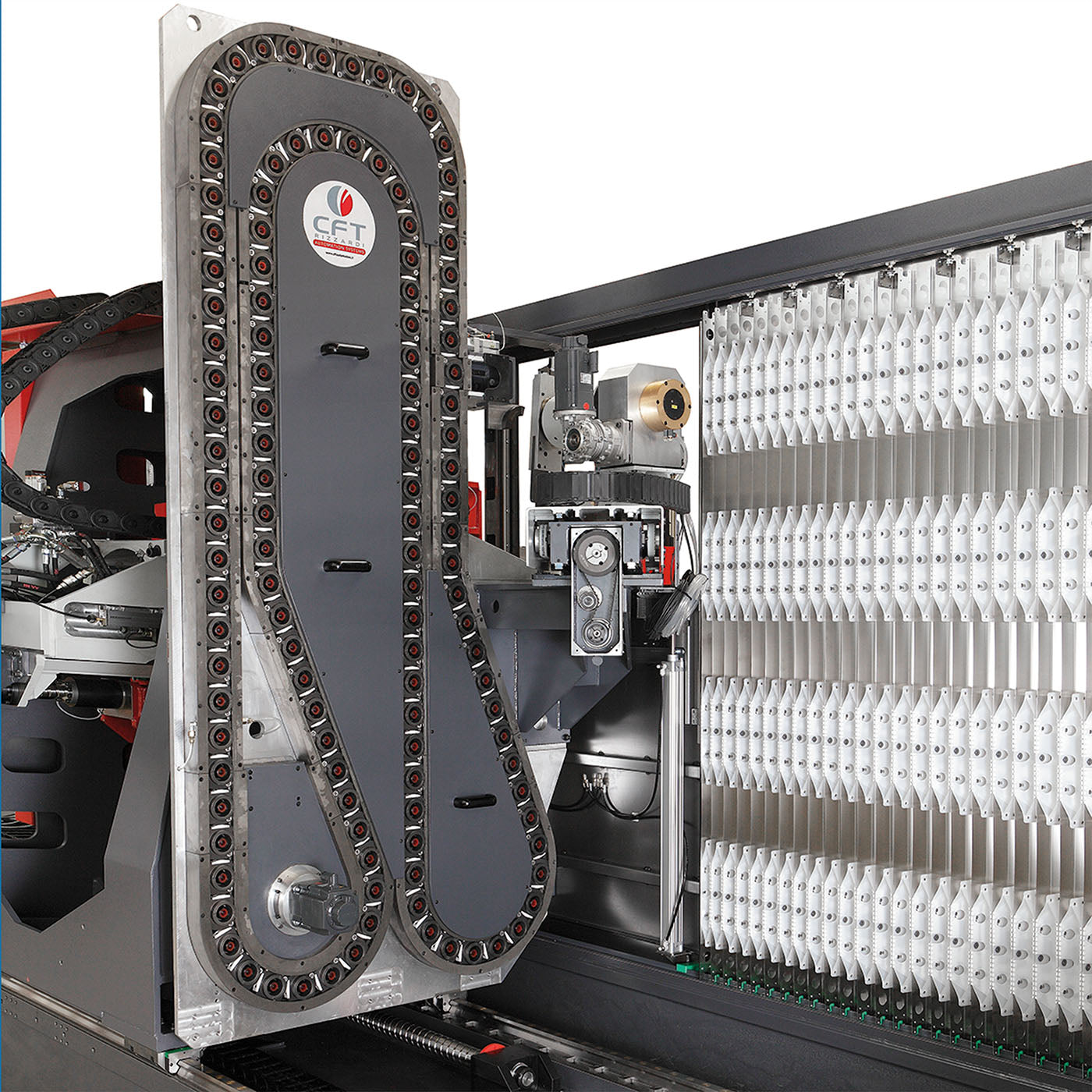

The rigid gantry design supports stable, vibration-free milling during heavy cuts and long cycles. Tool magazines up to 60 tools, an oversized work envelope, and optional rotary table support flexible fixturing, automation, and multi-face machining. Paired with Heidenhain TNC 640 control, the MMV 3200 delivers consistent surface quality and reliable contouring on demanding parts.

Country of Origin: Austria

Customize Your CNC

BEYOND STANDARD

The EMCO MMV 3200 is a heavy-duty gantry-style vertical machining center engineered for large, high-precision components. With powerful axis drives, dynamic 3D contouring, and a massive work envelope, it’s built to dominate aerospace, energy, and industrial-grade production. A rigid portal structure and powerful inline spindle deliver top-tier metal removal rates with uncompromising accuracy. The MMV 3200 thrives in demanding jobs that require flawless surface finish, high chip volume, and uninterrupted process reliability. With options like EMCONNECT and Heidenhain TNC 640, it’s automation-ready for tomorrow’s smart factories.

SPEED MEETS PRECISION

The EMCO MMV 3200 is engineered for high-speed, precise machining. Its main spindle operates up to 15,000 rpm, delivering a continuous torque of 92 ft-lb (125 Nm) and peaking at 125 ft-lb (170 Nm) for demanding cuts. The machine achieves rapid traverse speeds of 1,968 ipm (50 m/min) on the X-axis and 1,575 ipm (40 m/min) on both Y and Z axes, ensuring swift positioning and reduced cycle times. With acceleration rates up to 157 in/s² (4 m/s²), the MMV 3200 combines speed with stability, making it ideal for both heavy-duty and intricate machining tasks.

Tech Specifications

126" (3,200 mm) / 39.4" (1,000 mm) / 37.4" (950 mm)

1,968 ipm (50 m/min) / 1,575 ipm (40 m/min) / 1,575 ipm (40 m/min)

118 in/s² (3 m/s²) / 157 in/s² (4 m/s²) / 157 in/s² (4 m/s²)

±0.0002" (±0.005 mm) / ±0.0001" (±0.003 mm)

15,000 rpm / 125 ft-lb (170 Nm)

50 rpm / 1,475 ft-lb (2,000 Nm)

±5 arcsec / 2,950 ft-lb (4,000 Nm)

Torque-driven rotary table

Why Choose EMCO?

Precision engineered. Performance delivered.

Innovative Machining Solutions

EMCO develops flexible, high-performance machining systems built for industries like aerospace, automotive, and general manufacturing.

Built by EMCO

Every EMCO machine is designed and manufactured in-house, ensuring the highest level of quality, precision, and technological innovation.

Engineered for 24/7 Production

Designed for durability and efficiency, EMCO machines deliver stable performance in demanding, multi-shift environments.

Comprehensive Lifecycle Support

From installation to maintenance and upgrades, EMCO provides full-service support to maximize uptime and productivity.

Global Reach, Local Expertise

With worldwide manufacturing and service hubs, EMCO delivers reliable solutions and expert support wherever you operate.