EMCO HT65 Powermill G1 High-Performance Turn-Mill Center

Financing options available.

Built for Machinists. Engineered for Performance.

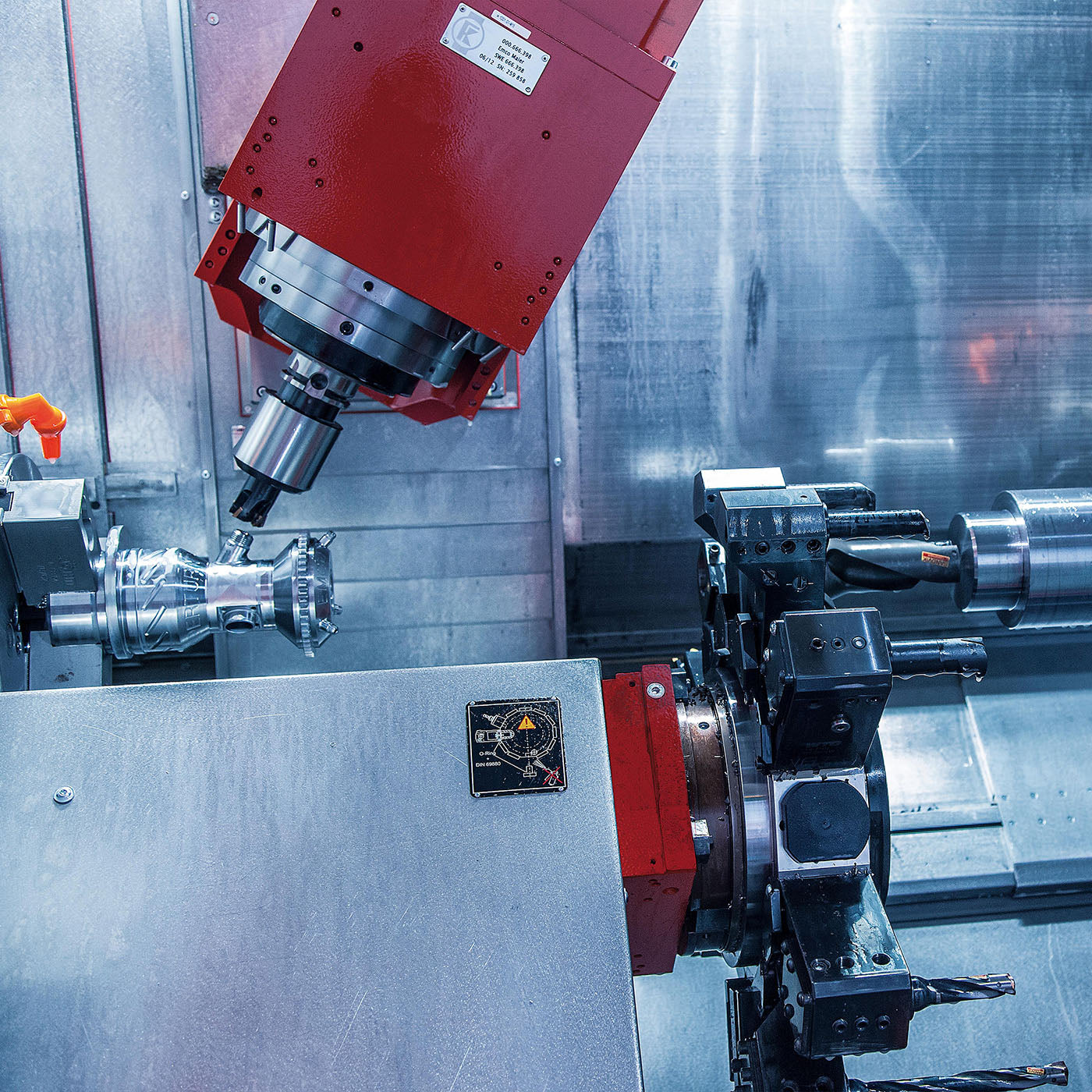

The EMCO HYPERTURN 65 Powermill G1 is a serious machine for serious work. With a main and counter spindle that handles bar stock up to Ø3.74" (Ø95 mm), plus a ±110° B-axis milling spindle, it powers through turning, milling, and drilling in one seamless setup. Whether you’re machining high-strength steels, aerospace titanium, or nickel-based superalloys, this machine doesn’t flinch. The 12-station tool turret keeps production moving, cutting cycle times and boosting efficiency.

Need flexibility? This beast comes with an HSK-T63 milling spindle and an optional tool magazine with up to 80 tools—so you can load it up and keep chips flying. A secondary Y-axis on the turret expands milling and drilling capability, making it a go-to for industries demanding precision—automotive, aerospace, medical, and beyond.

Built for durability, the HYPERTURN 65 PM G1 runs on pre-stressed roller guides for rock-solid rigidity. EMCONNECT digital control keeps workflows seamless, and its automation-ready setup makes lights-out manufacturing a reality. Whether you’re cranking out production runs or tackling tough materials, this machine delivers.

Country of Origin: Austria

BEYOND STANDARD

The EMCO HYPERTURN 65 Powermill G1 is a powerhouse mill-turn center built for multi-tasking precision machining. With a ±110° B-axis milling spindle, high-torque main and counter spindles, and an optional 80-tool magazine, it’s engineered for cutting tough materials like stainless steel, Inconel, and titanium. The integrated Y-axis expands milling and drilling capabilities, while advanced automation and EMCONNECT digital control streamline complex production. Perfect for aerospace, defense, and medical industries, this machine delivers faster cycle times, seamless workflows, and pinpoint accuracy—no matter the job.

SPEED MEETS PRECISION

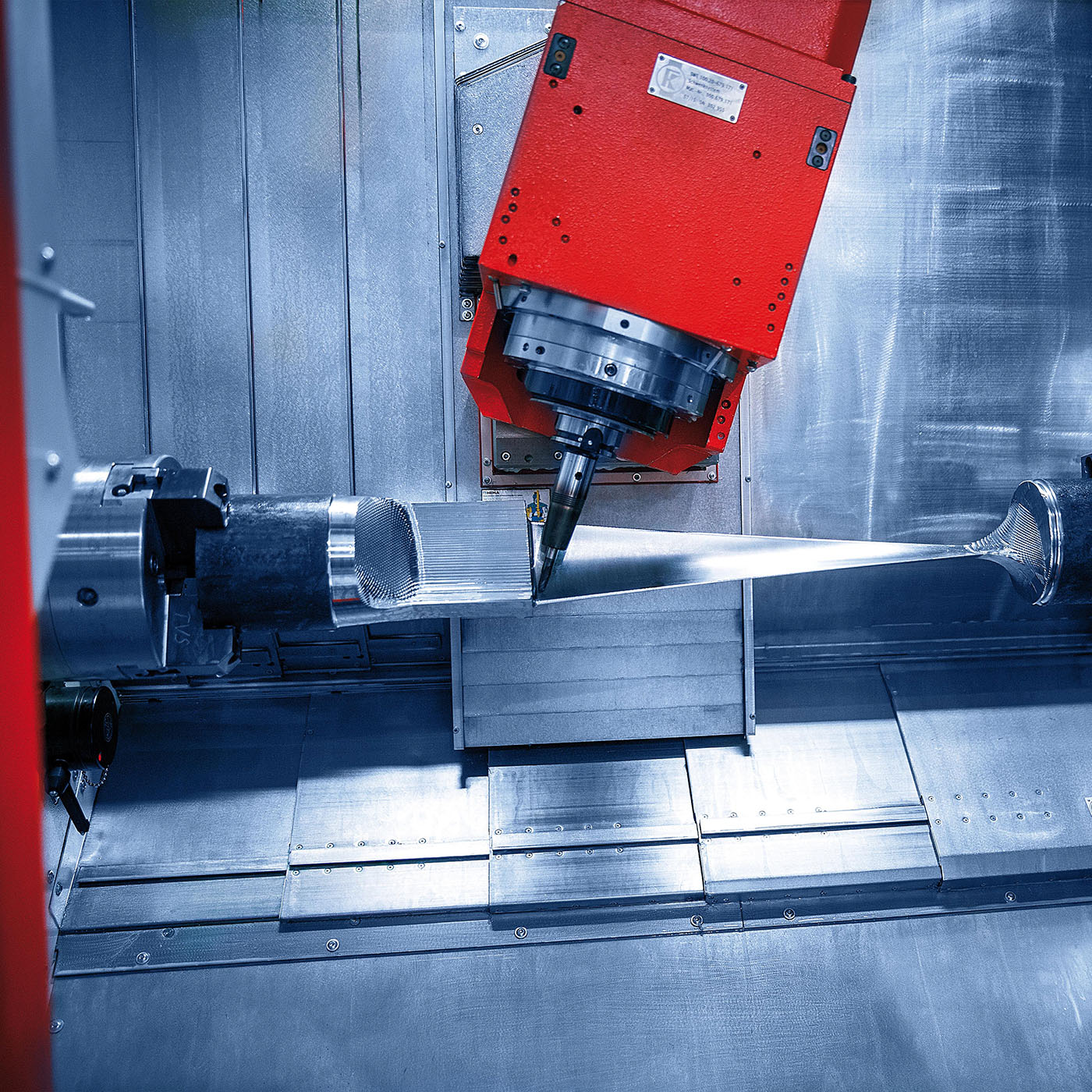

The B-axis milling spindle of the HYPERTURN 65 Powermill G1 delivers speeds up to 12,000 rpm with 81.1 ft-lb (110 Nm) of torque, ensuring high-speed, precise machining. The main spindle reaches 5,000 rpm, providing the power needed for both aluminum milling and heavy-duty steel turning. Direct-drive technology and rigid roller guides maintain stability, accuracy, and long-term reliability.

Tech Specifications

11.8" / ±3.9" / 47.2" (300 mm / ±100 mm / 1200 mm)

1,181 in/min / 472 in/min / 1,181 in/min (30 m/min / 12 m/min / 30 m/min)

9.8 ft/s² / 9.8 ft/s² / 9.8 ft/s² (3 m/s² / 3 m/s² / 3 m/s²)

0.00016" (4 µm) / 0.00008" (2 µm) / 0.00016" (4 µm)

±110° / 73.8 ft-lb (100 Nm)

0 - 5000 rpm / 184 ft-lb (250 Nm)

±5 arcsec / 2,950 ft-lb (4000 Nm)

B-Axis milling spindle

Why Choose EMCO?

Precision engineered. Performance delivered.

Innovative Machining Solutions

EMCO develops flexible, high-performance machining systems built for industries like aerospace, automotive, and general manufacturing.

Built by EMCO

Every EMCO machine is designed and manufactured in-house, ensuring the highest level of quality, precision, and technological innovation.

Engineered for 24/7 Production

Designed for durability and efficiency, EMCO machines deliver stable performance in demanding, multi-shift environments.

Comprehensive Lifecycle Support

From installation to maintenance and upgrades, EMCO provides full-service support to maximize uptime and productivity.

Global Reach, Local Expertise

With worldwide manufacturing and service hubs, EMCO delivers reliable solutions and expert support wherever you operate.