DX224DM 5-Axis Double Column Vertical Machining Center

Financing options available.

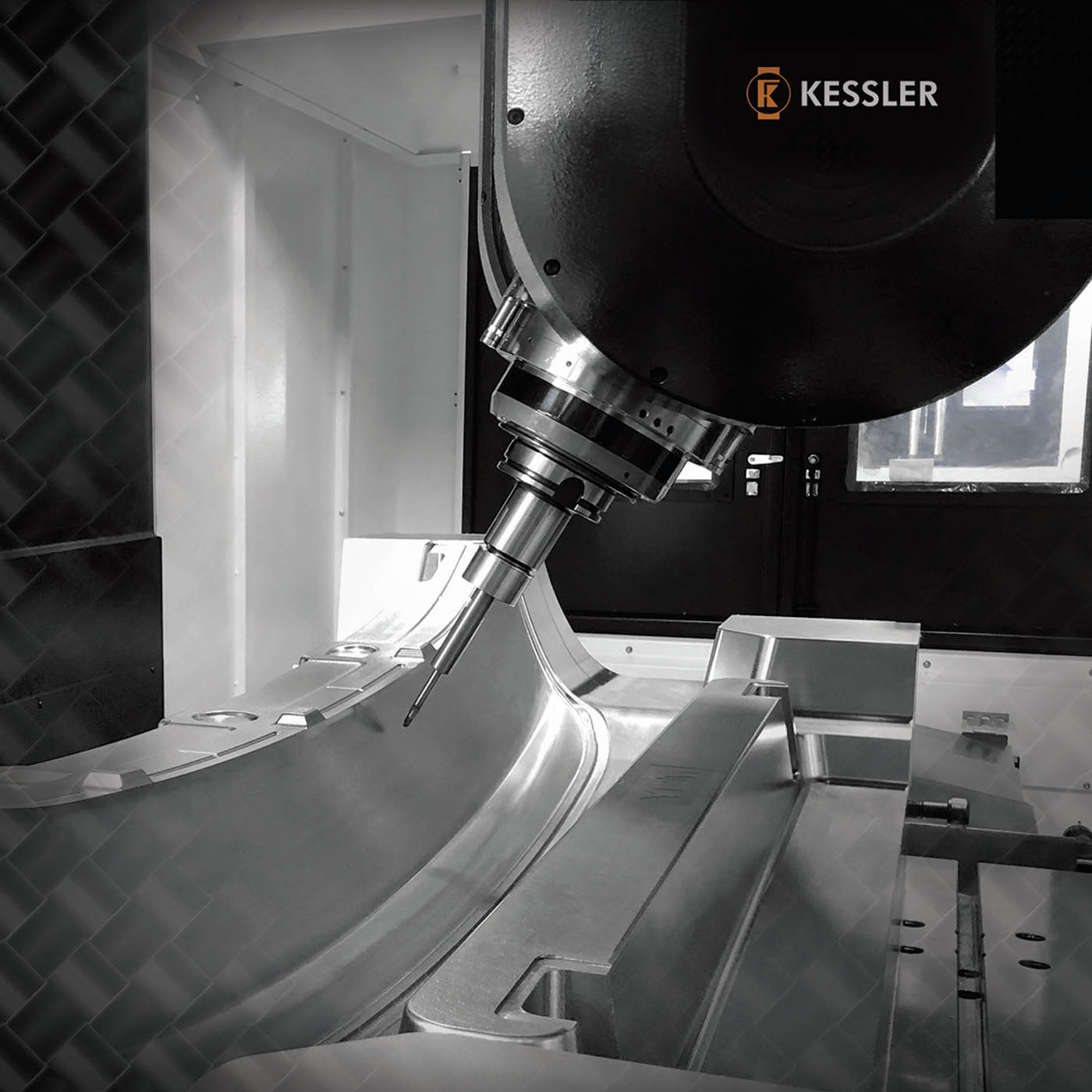

Bridge-Style Power for Large-Scale Precision

The YCM DX224DM is a double column, 5-axis vertical machining center engineered for massive workpieces. With a tilting spindle head and full 5-face capability, the DX224DM handles heavy-duty cuts and complex geometries in aerospace, mold & die, and energy sectors. Its rigid construction and high torque spindle make it a powerful option for shops ready to scale up.

Country of Origin: Taiwan

Customize Your CNC

SCALE WITHOUT COMPROMISE

Designed for large-part machining with 5-axis flexibility, the DX224DM gives you the accuracy of a bridge mill and the reach of a tilting head. With table loads up to 11,000 lbs and long-travel axes, this machine is purpose-built for molds, tooling, and aerospace components. A high-torque spindle and dual-column frame ensure reliable cuts on demanding materials.

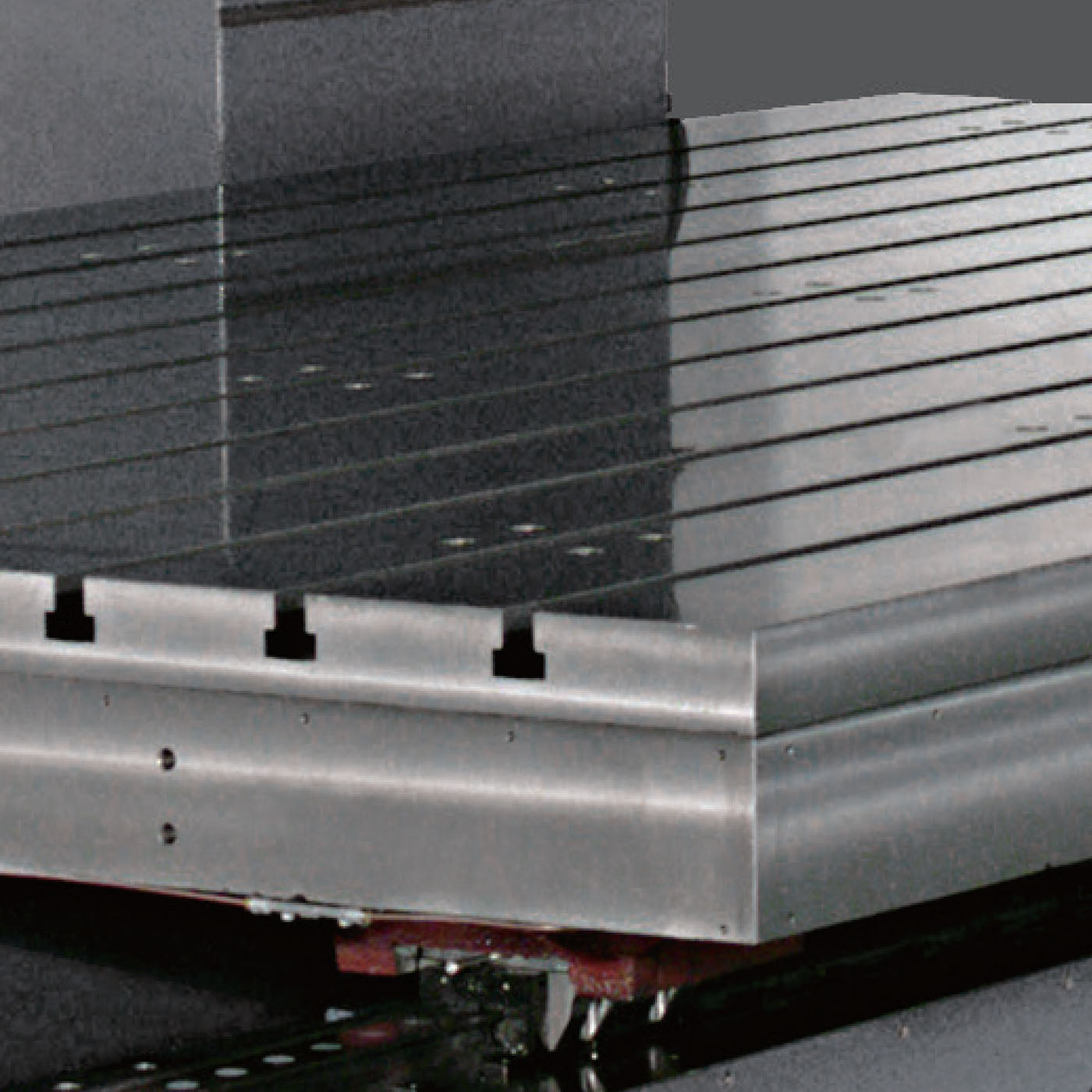

Highly Rigid Structural Design

- All castings designed with strategically located rib support using FEM analysis.

- One-piece double column bridge casting.

- One-piece base casting.

- Wide-span saddle casting fully supports the Z-axis head in any machining direction.

- Rigid Z-axis head casting designed to avoid overhang, increase stiffness, and reduce vibration.

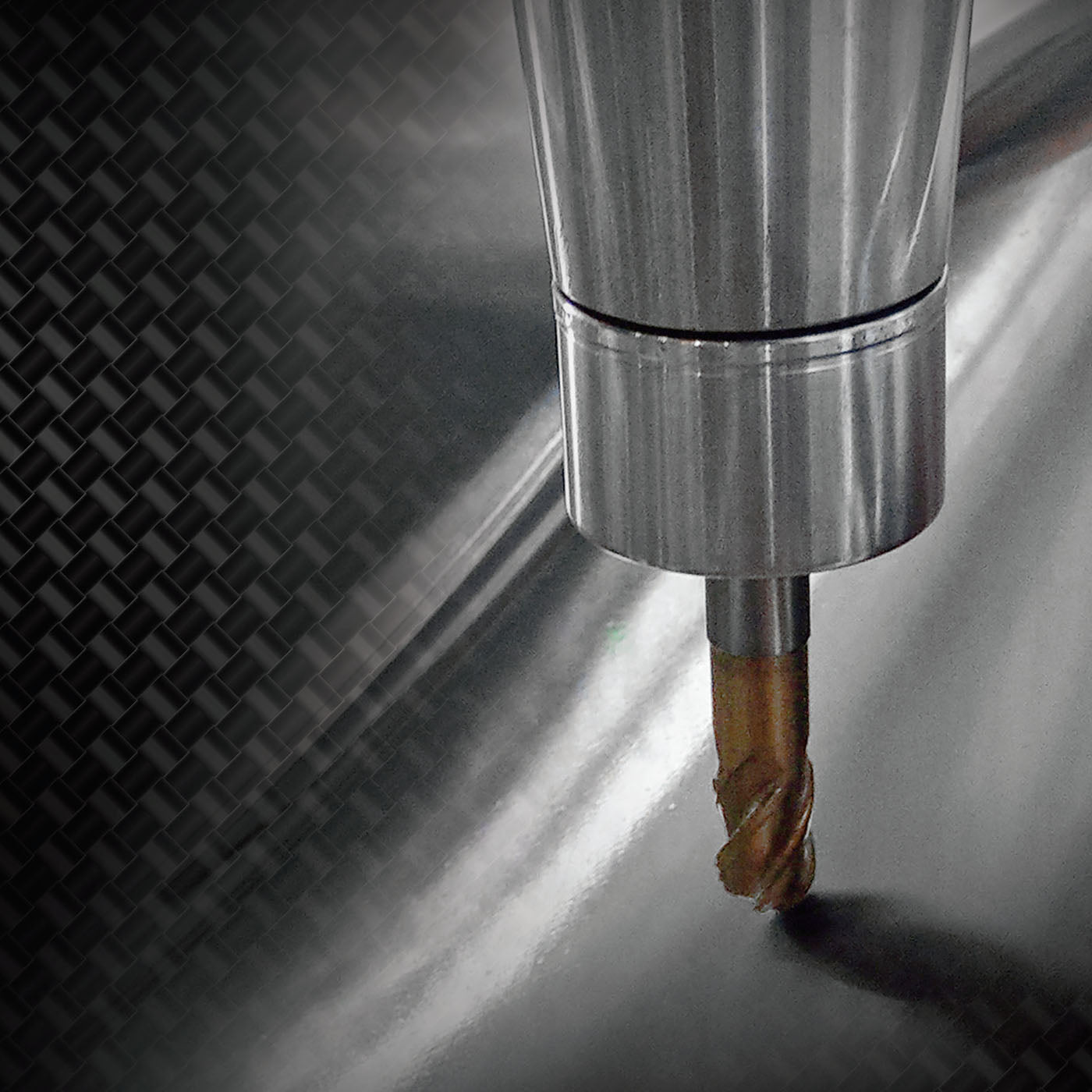

Highly-Rigid Linear Motion Guideways

- Linear X/Y/Z-axis (DX) and linear X/Y-axis with box guideway Z-axis (D).

- Roller-type blocks and guiderails.

- Fast, smooth, accurate.

- High load capacity.

- Y-axis linear guideways have a wide span for greater support.

Tech Specifications

86.6" × 94.5" × 31.5" (2200 × 2400 × 800 mm)

86.6" × 86.6" (2200 × 2200 mm)

13,228 lbs (6,000 kg)

Fanuc 31i-B5

12,000 RPM

49.6 hp (37 kW)

HSK-A100

60 tools

±105° B-Axis, 360° C-Axis

Heavy-duty machining with large capacity and twin columns

Why Choose YCM Alliance?

Precision you can count on.

True Machine Tool Builders

YCM designs and casts its own bases, manufactures its own spindles, and hand-scrapes critical surfaces—ensuring unmatched quality control.

High-Mix Machining Capability

Whether you run aerospace, die/mold, or medical parts, the YCM Alliance lineup—from YCM CNC to TRIMILL to exeron to ZIERSCH to CHETO and MILLUTENSIL—delivers high-precision, high-mix solutions built for every machining need.

Automation-Ready Design

From auto doors and pallet changers to full robotic cells, YCM Alliance machines are designed for integration and lights-out scalability.

Industry-Leading Component Brands

Built with top-tier components including Heidenhain, FANUC, HSK, and Rexroth, these machines deliver both reliability and long-term performance.

Built for Longevity

With heavy-duty cast iron construction, thermal stability systems, and proven engineering, these machines are made to hold tolerances—year after year.