Learn more about each project and the machine tools, tooling, software, and accessories used to machine them.

STATION 29: Sinker Demo

| Machinist | David Pedersen |

| Machine | SODICK AL40G |

| Part Name | TITAN-868 – 2 Piece Mold |

| Material & Provider | 420 Stainless and MoldMAX HH |

| Industry | Injection Molding |

| Control | SP |

| Programmed In | LNPRO |

| Workholding | Magnet on Erowa Pallet |

| Coolant | Blaser |

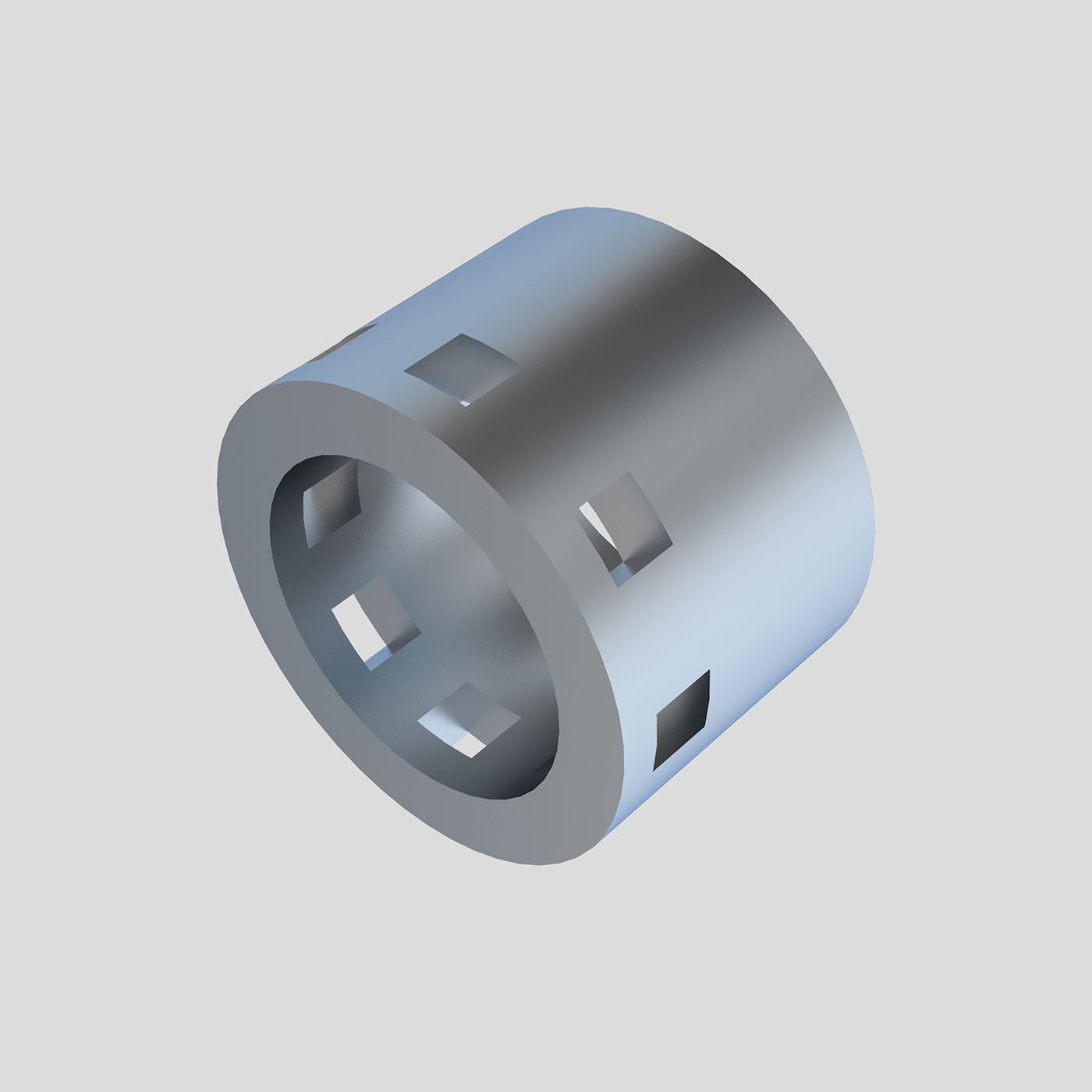

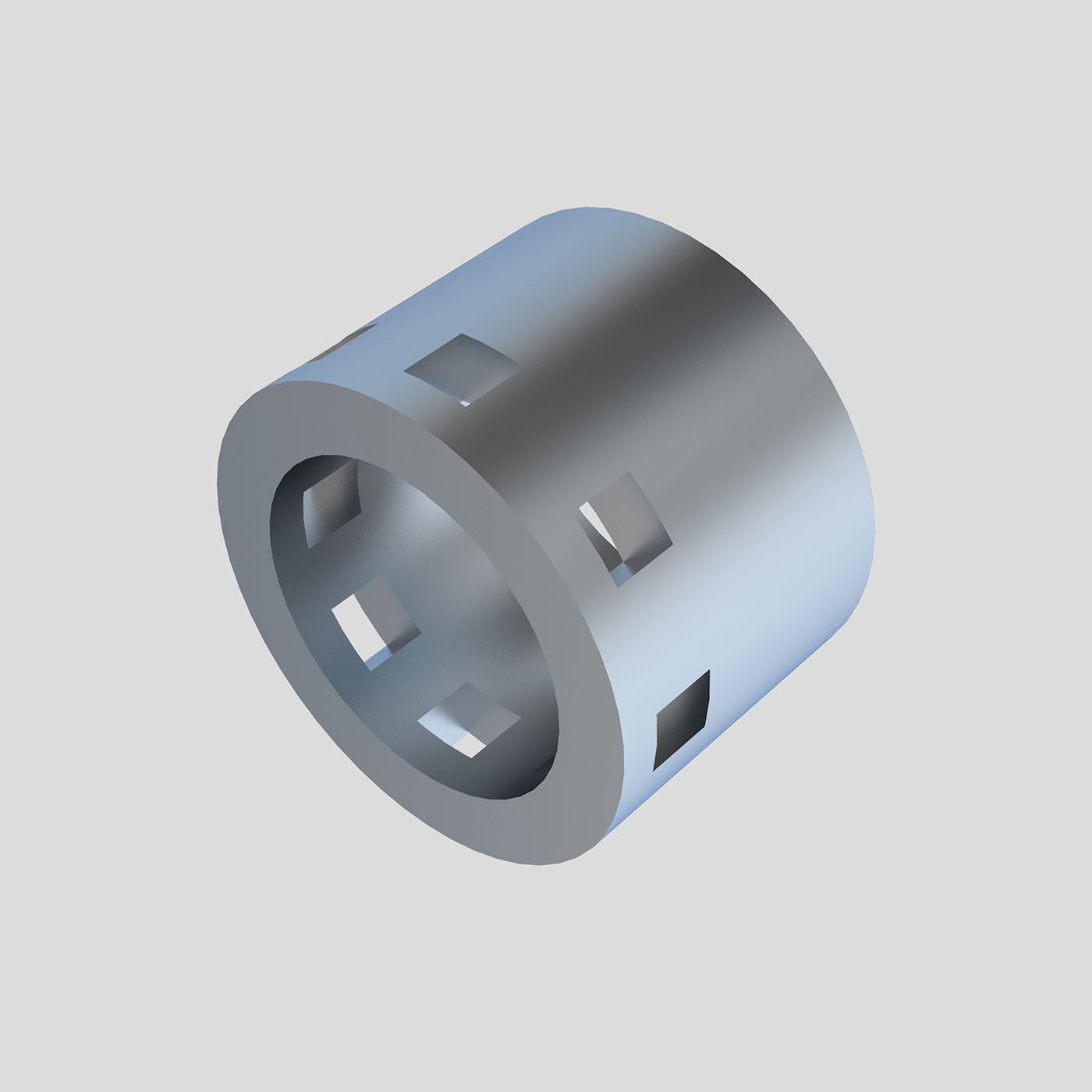

TITAN-871 "Oil Shaft"

| Machinist | David Pedersen |

| Machine | SODICK AL40G |

| Part Name | TITAN-871 – Oil Shaft |

| Material & Provider | H13 Steel |

| Industry | Oil Refinery |

| Control | SP |

| Programmed In | LPPRO |

| Workholding | Magnet on Erowa Pallet |

| Coolant | Blaser |

TITAN-871 "Oil Shaft"

| Machinist | David Pedersen |

| Machine | SODICK AL40G |

| Part Name | TITAN-871 – Oil Shaft |

| Material & Provider | H13 Steel |

| Industry | Oil Refinery |

| Control | SP |

| Programmed In | LPPRO |

| Workholding | Magnet on Erowa Pallet |

| Coolant | Blaser |

SODICK SR12

SODICK SR12 — Robotic Cell for EDM

SR12 automates palletized loading and job queuing on Sodick EDM platforms—steady burn conditions, repeatable datums, and true lights-out operation for small-feature accuracy over long runs.

| Automation Scope | Pallet exchange, part loading, offsets handshaking, queue control |

| Compatibility | Sodick wire & sinker EDM (cell/config dependent) |

| Palletized Repeatability | Stable datums for consistent size/finish across unattended cycles |

| Quick-Change Tooling | EDM systems such as EROWA / System 3R (per build) |

| Lights-Out Safeguards | Guarding, interlocks, status I/O, alarm/notification, restart logic |

SODICK SR12

SODICK SR12 — Robotic Cell for EDM

SR12 automates palletized loading and job queuing on Sodick EDM platforms—steady burn conditions, repeatable datums, and true lights-out operation for small-feature accuracy over long runs.

| Automation Scope | Pallet exchange, part loading, offsets handshaking, queue control |

| Compatibility | Sodick wire & sinker EDM (cell/config dependent) |

| Palletized Repeatability | Stable datums for consistent size/finish across unattended cycles |

| Quick-Change Tooling | EDM systems such as EROWA / System 3R (per build) |

| Lights-Out Safeguards | Guarding, interlocks, status I/O, alarm/notification, restart logic |

Featured at This Station

AL40G Die-Sinker EDM

The TITANS of CNC Promise

- Expert Guidance

- Flexible Financing

- Service & Support

- Industry Connections

Product Info

The AL40G features a 15.7 × 11.8 × 13.8 in (400 × 300 × 350 mm) work tank with a compact footprint and full closed-loop positioning. Its linear motors, Sodick’s exclusive Smart Pulse generator, and 0.000004 in (0.1 µm) digital resolution ensure stable spark control and repeatable performance. Designed for energy efficiency and minimal electrode wear, it’s ideal for precision mold and die production.

Additional Tooling Used at This Station

Listed for your convenience. Availability and specs may change.

Erowa ITS 50