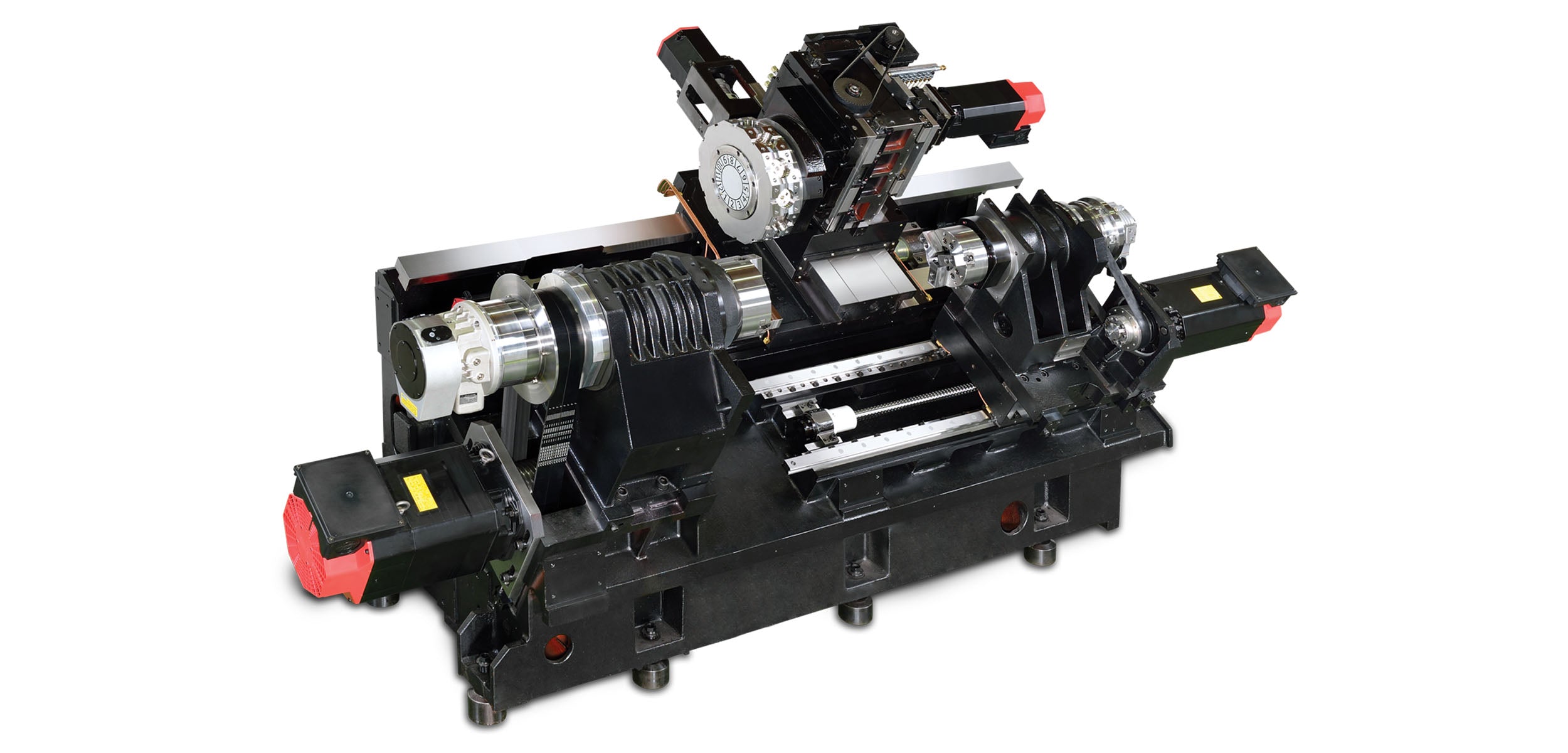

B8-SY 6-Axis Turn-Mill Center

Financing options available.

Twin-Spindle Y-Axis Turning Center for Complex Parts

The YCM B8SY is a 6-axis turn-mill center that combines dual spindles, Y-axis capability, and live tooling in one rigid platform. With precision hand-scraped slideways, a 30° slant-bed Meehanite® casting, and thermal-stable design, it’s made to produce complex components in a single setup with accuracy and efficiency.

Country of Origin: Taiwan

Customize Your CNC

Built for Done-in-One Machining

The YCM B8-SY pairs an 8-inch main spindle and 6-inch sub-spindle with full C- and Y-axis control. Its 12-station BMT-55 turret supports live tools up to 4,000 rpm, and both spindles offer synchronized turning and part transfer for done-in-one production. Ideal for aerospace, medical, and high-precision industries, it delivers excellent surface finishes and tight part-to-part repeatability.

Rigid Design

FEM analysis ensures rib and mass placement for maximum stability under heavy cutting loads. Rugged castings provide stiffness, thermal stability, and vibration control for consistent accuracy.

Spindle

YCM Turning Centers are built for flexibility, covering everything from general job shop work to high-end parts machining. Perfect for automotive, aerospace, medical, energy, and more.

Designed for Versatility

The spindle is the heart of every machine. YCM’s proven spindle design delivers long life, reliable performance, and the rigidity needed for tough cuts and repeatable precision.

Tech Specifications

6.3 / ±1.97 / 22.4 in (160 / ±50 / 570 mm)

FANUC TXP-200FB+

5,000 / 6,000 rpm

40.2 / 14.8 hp (30 / 11 kW)

12 Stations (BMT-55 Turret)

B-Axis 25.6 in (650 mm) + Y-Axis ±1.97 in (±50 mm)

Y-axis, sub-spindle, BMT-55 live turret, slant-bed rigidity, thermal balance

Why Choose YCM Alliance?

Precision you can count on.

True Machine Tool Builders

YCM designs and casts its own bases, manufactures its own spindles, and hand-scrapes critical surfaces—ensuring unmatched quality control.

High-Mix Machining Capability

Whether you run aerospace, die/mold, or medical parts, the YCM Alliance lineup—from YCM CNC to TRIMILL to exeron to ZIERSCH to CHETO and MILLUTENSIL—delivers high-precision, high-mix solutions built for every machining need.

Automation-Ready Design

From auto doors and pallet changers to full robotic cells, YCM Alliance machines are designed for integration and lights-out scalability.

Industry-Leading Component Brands

Built with top-tier components including Heidenhain, FANUC, HSK, and Rexroth, these machines deliver both reliability and long-term performance.

Built for Longevity

With heavy-duty cast iron construction, thermal stability systems, and proven engineering, these machines are made to hold tolerances—year after year.