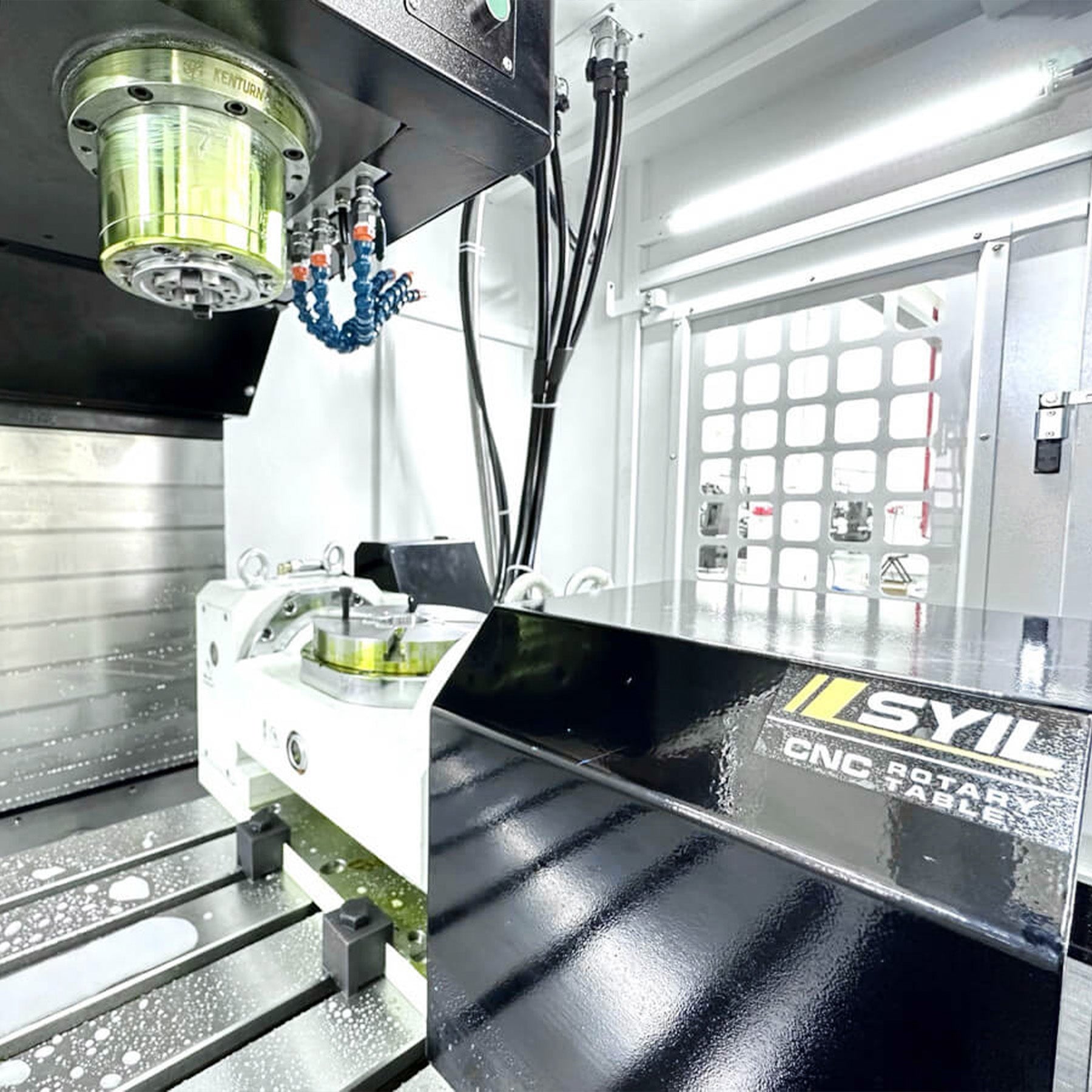

SYIL X11 Vertical Machining Center

Prices Starting at:

Financing options available.

Product Info

Designed for Large Workpieces

- Axis travels of 39.37" × 19.69" × 19.69" (1000mm × 500mm × 500mm)

- 24-pocket high-speed servo auto tool changer (Arm Type)

- 12,000RPM CT40 spindle

- High-quality Epoxy Granite frame by SCHNEEBERGER (Swiss)

- SIEMENS 828D 15" touch screen CNC Controller with 3-axis Servo Motors

Country of Origin: Parts sourced from multiple countries. Machine tool assembled in China; packaged and shipped in the USA.

Customizations

- 24,000RPM HSK-A63 Build-in Type with Power Drawbar System (not available for SIEMENS controller)

- NC rotary table servo type

- 4th axis 250mm size kits including servo motors and driver

- Taiwan Made and Gear type

- Tail Stock for 125mm NC rotary table

- Probe System: Wireless type

- Tool Setter Kits: Cable type TTC200

- Filtermist

- Through Spindle Coolant (20 Bar)

- Chip Conveyor

SYIL X11

This affordable and versatile vertical machining center is perfect for medium and large workpieces. Excelling in both ferrous and non-ferrous materials, the SYIL X11 delivers high-quality results while efficiently surpassing industry standards.

41.34" x 21.65" (1050 x 550mm)

0.71" x 0.20" x 3.54" (18 x 5 x 90mm)

1322.77 lbs (600kg)

106.30" x 90.55" x 110.24" (2700 × 2300 × 2800mm)

39.37" (1000mm)

19.69" (500mm)

19.69" (500mm)

4.33"-24.01" (110 - 610mm)

25.59" (650mm)

CT40

12,000 rpm / 10,000 rpm

Direct/Belt

393.70"/min (10,000mm/min)

1181.10"/min (30,000mm/min)

SCHNEEBERGER

High-precision mineral casting bed

THK

High-precision ball screws and linear guides

4th Axis

Optional 4th-Axis

High-Speed Servo Tool Changer

24 position, BT40

Robert S.

TITANS of CNC delivered a 5-star experience! Titan and Jessie went above and beyond to personally educate me about the SYIL X7. Keith made everything super easy and answered no less than 1,000 of my questions. Their team really cared about my success! All that's left is for me to finalize the machine's placement and see what this thing can do. Can't wait to cut my first chips on this bad boy!

Why Choose the X11 Vertical Machining Center?

There are several advantages to using an X11 Vertical Machining Center for your machining needs.

Excellent Features

- Strong and reliable performance

- Compact machine layout

- Mineral cast bed

- High rigidity and good thermal stability

- Electric spindle with water cooling function

Sleek Design

- Fully enclosed working area with stainless steel guard plate

- Designed for easy chip removal

- Ergonomic operation and workpiece loading/unloading

- Easy access to equipment units for maintenance

- Expandable and customizable automation system

Versatile and Cost-Effective

The cost-effective X11 offers a compact design, making it ideal for companies looking to optimize their space.

Its user-friendly interface and software ensure easy operation, while its high-quality construction guarantees durability.

Whether you're machining a variety of materials, or want an affordable solution for your production line, the SYIL X11 is a smart investment that checks both boxes.

Additional Features

Arm Type

24 Positions

4.72" (120mm)

11.81" (300mm)

15.43 lbs (7kg)

2.5s

14.75/22.80 hp (11/17kW)

5.23/5.23/7.92 hp (3.9/3.9/5.9kW)

AC380V/ 3-Phase

106.30" x 90.55" x 110.24" (2700 × 2300 × 2800mm)

15432.36 lbs (7000kg)