Learn more about each project and the machine tools, tooling, software, and accessories used to machine them.

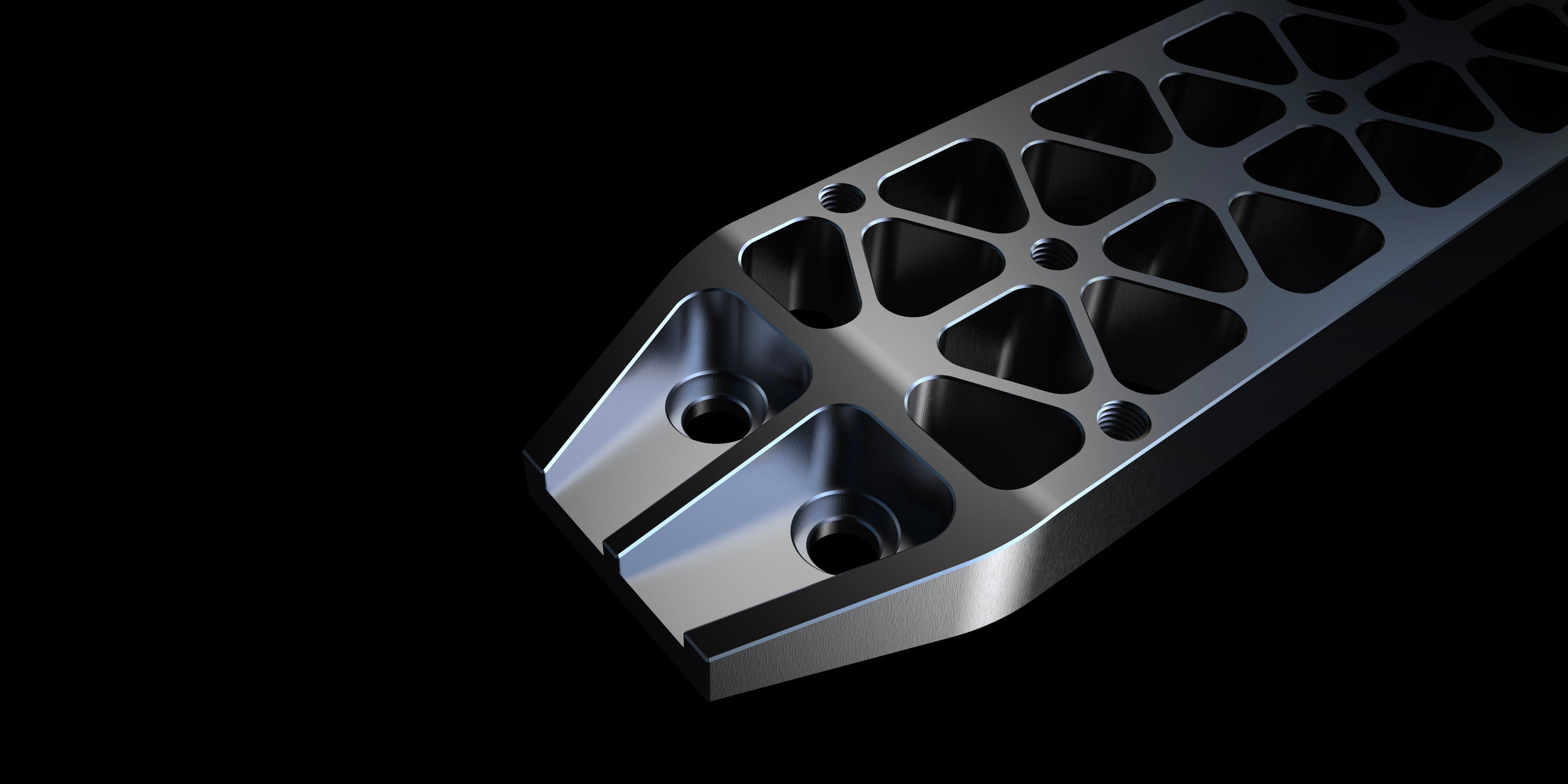

STATION 16: LOWER FRAME BASE in ALUMINUM CNC MACHINED on a HELLER HF5500 with KENNAMETAL TOOLING

| Part | Lower Frame Base |

| Industry | Aerospace |

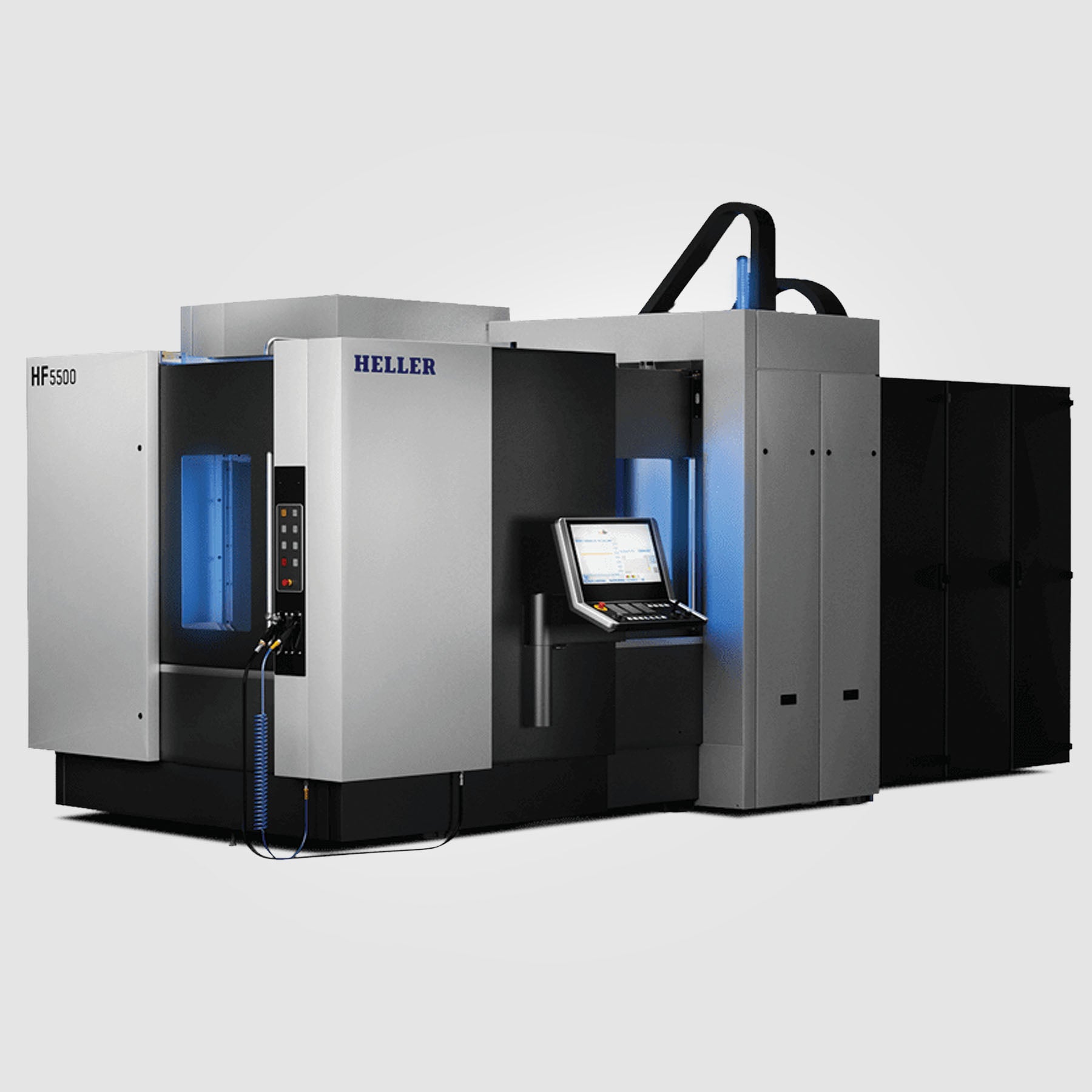

| Machine | HELLER HF5500 |

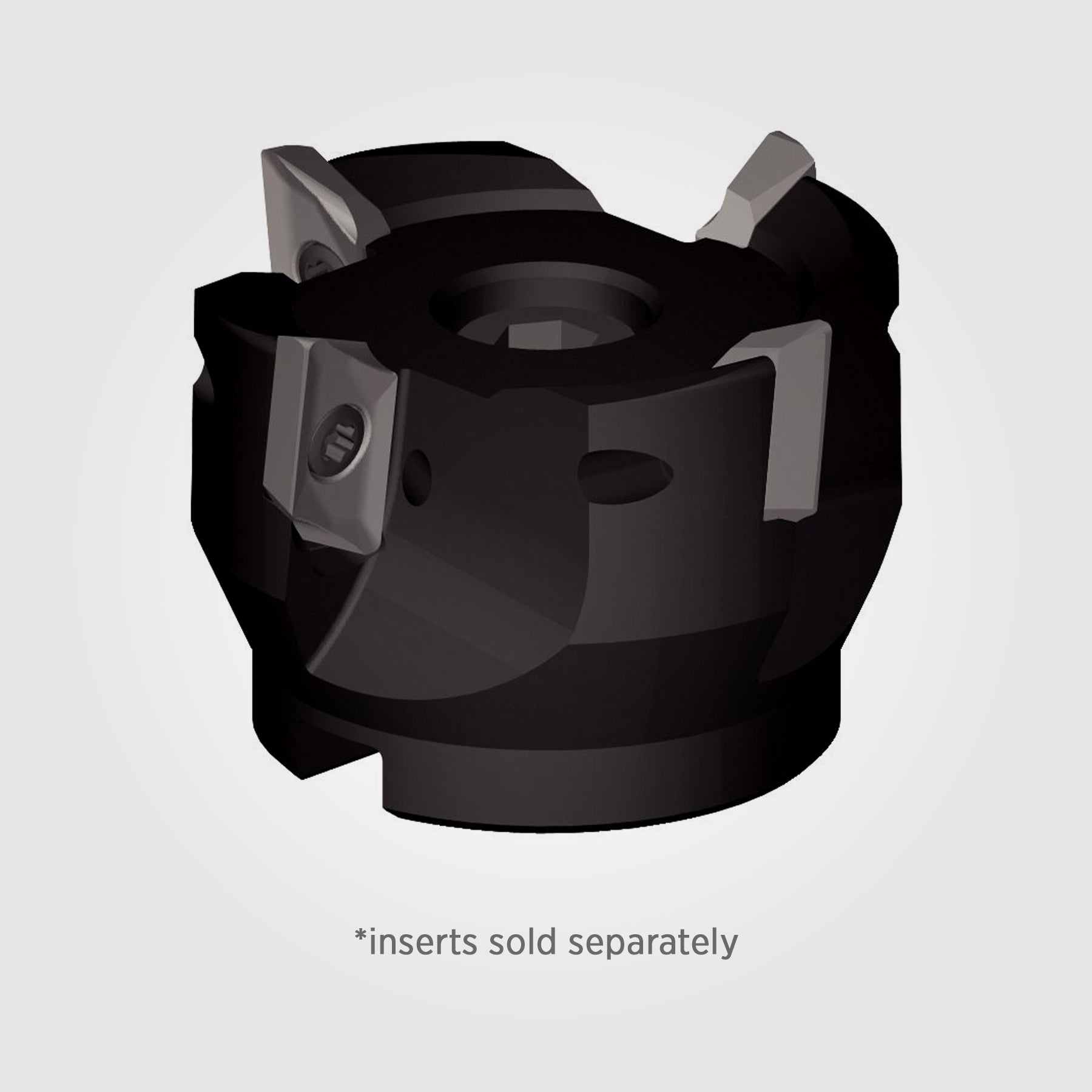

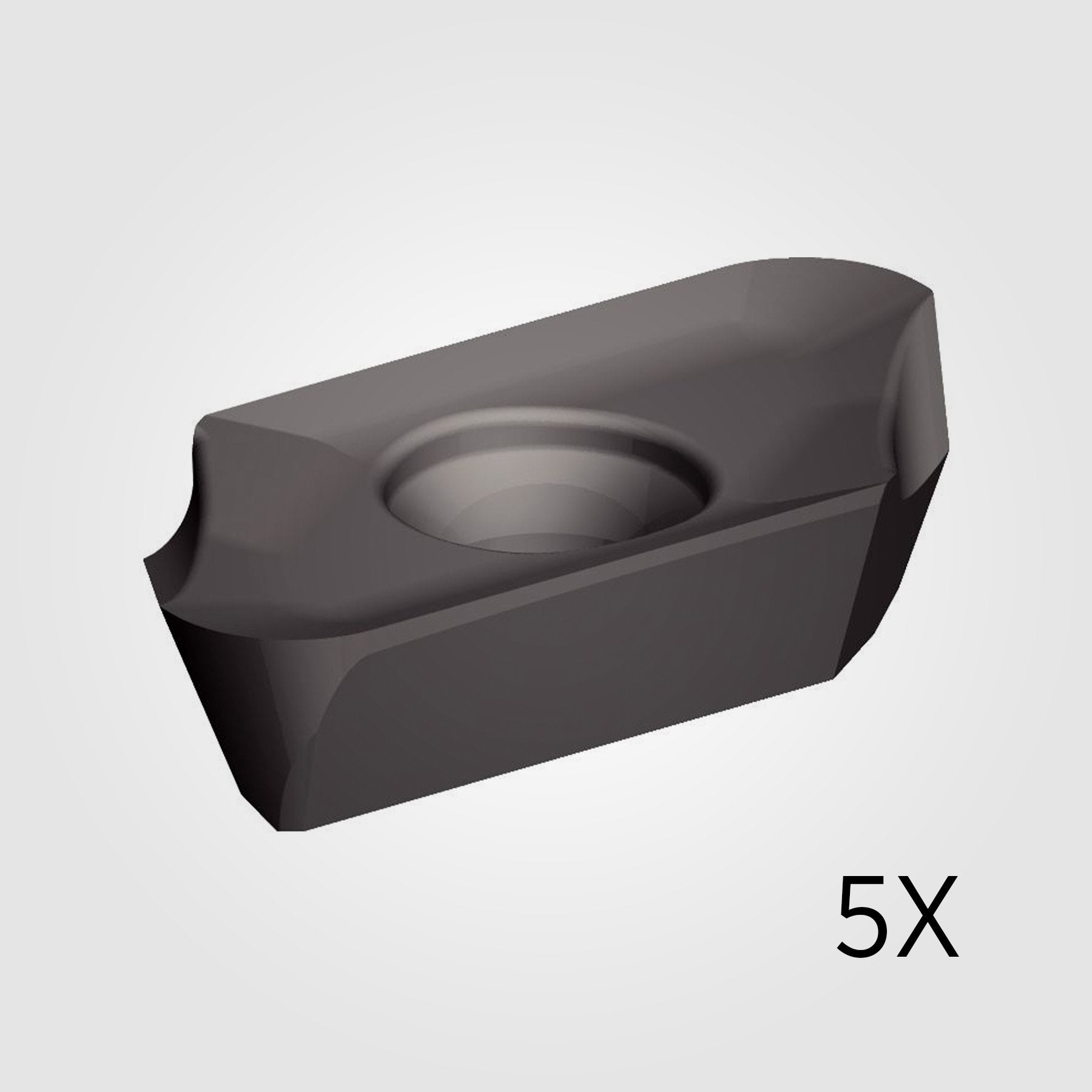

| Tooling | Kennametal Tooling |

| Material | 6061 Aluminum |

Featured in this Project

HELLER HF5500

The HELLER HF5500 is a high-performance horizontal machining center designed for complex, heavy-duty milling operations. It combines robust construction with advanced technology to deliver exceptional precision and productivity, making it ideal for machining large and intricate parts in sectors like automotive and aerospace engineering.

SCHUNK KSX-C2 125-430 VISE

The Schunk KSX-C2 Vise high-precision clamping tool designed for quick and flexible setup on CNC machines. It features optimized guiding accuracy and a powerful clamping system that delivers exceptional force and stability for a variety of machining operations. The KSX-C2 125-430 model is renowned for its durability and reliability, making it a favored choice in demanding environments where quick adjustments and robust performance are crucial.

Hardware, software, tooling, coolant, workholding, and more used in the demonstration of this project during the BOOMBASTIC OPEN HOUSE EVENT.

HELLER HF5500 with Siemens 840D Control

SOLIDWORKS

Mastercam

Schunk KSX-C2 125-430 VISE

Blaser Swisslube SYNERGY 735

Kennametal KOR-5 DA 3/4" 5 Flute Solid Carbide Endmill

SFM: 2,552 | IPM: 2,000

Kennametal Kenn Universal Drill 1/2" 8xD KCU15 (MM# 2658412)

SFM: 750 | IPM: 30