Learn more about each project and the machine tools, tooling, software, and accessories used to machine them.

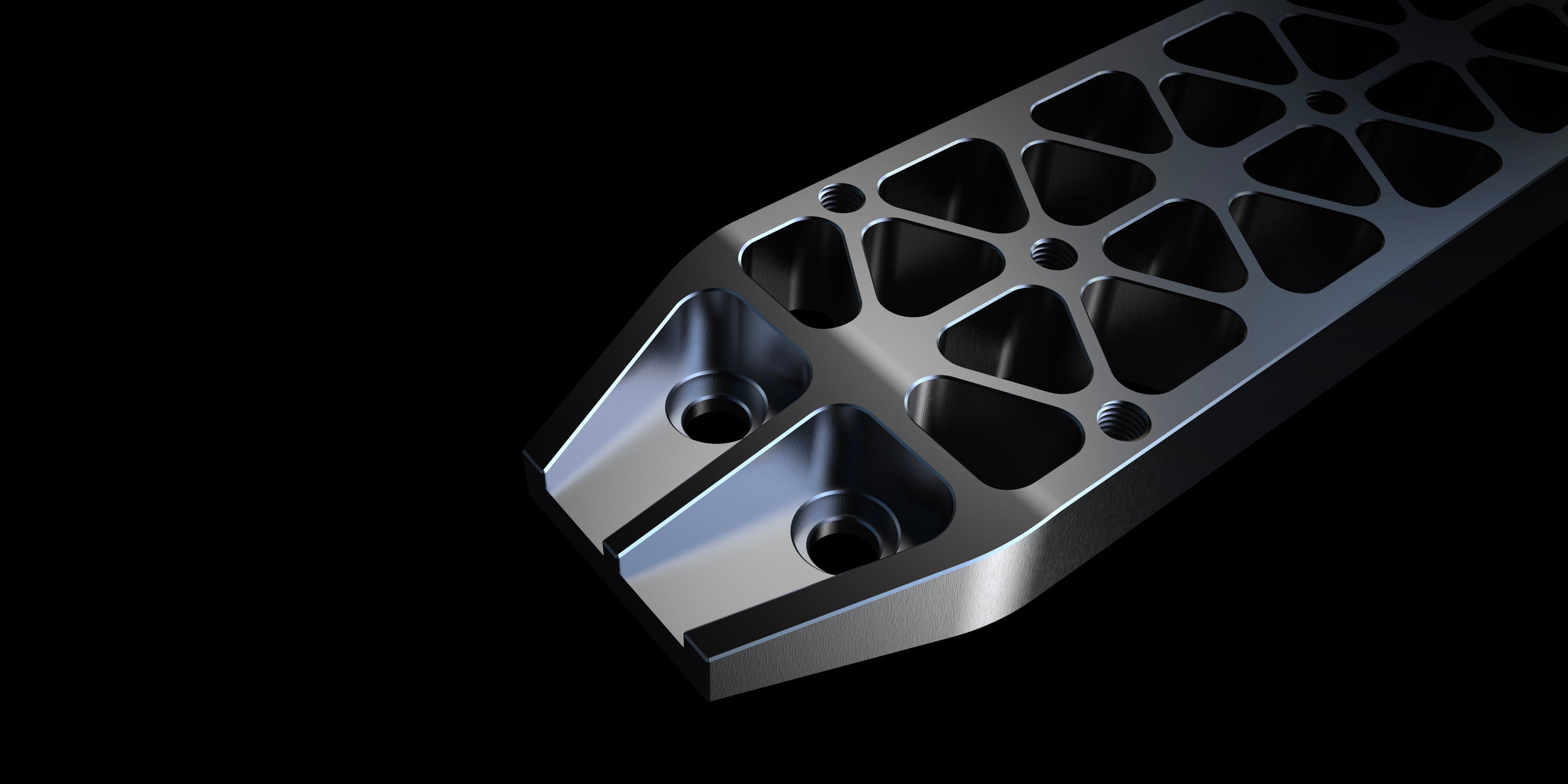

STATION 06: CRITICAL LINKAGE in STEEL CNC MACHINED on a DN SOLUTIONS BVM 5700 with KENNAMETAL TOOLING

| Part | Critical Linkage |

| Industry | Oil & Gas |

| Machine | DN Solutions BVM 5700 |

| Tooling | Kennametal Tooling |

| Material | 1018 Steel |

Featured in this Project

DN Solutions BVM 5700

Unlock next-level precision and speed with the DN Solutions BVM 5700 Vertical Machining Center, a high-end model designed for rigorous die/mold applications. This machine features a high-speed 15,000 RPM spindle, advanced thermal displacement controls, and a stable bridge-type structure, ensuring high productivity and outstanding machining quality.

Schunk MFRS-A1-050 1000 x 500

Optimize your workflow with the Schunk MFRS-A1-050 Magnet Table, offering a stable and secure hold for a variety of metal workpieces. Its dimensions of 1000 x 500 mm provide ample surface area, making it ideal for efficient, high-precision machining.

Hardware, software, tooling, coolant, workholding, and more used in the demonstration of this project during the BOOMBASTIC OPEN HOUSE EVENT.

DN Solutions BVM 5700 with Fanuc Control

Schunk "Magnet Table" MFRS-A1-050 1000 x 500

Blaser Swisslube SYNERGY 735

Kennametal KOR-6 3/4" 6 Flute Solid Carbide Endmill

SFM: 1,250 | IPM: 200

Kennametal HARVI I TE 1/2" Endmill

SFM: 650 | IPM: 40

Kennametal KOR-6 1/2" 6 Flute Solid Carbide Endmill

SFM: 1,100 | IPM: 300