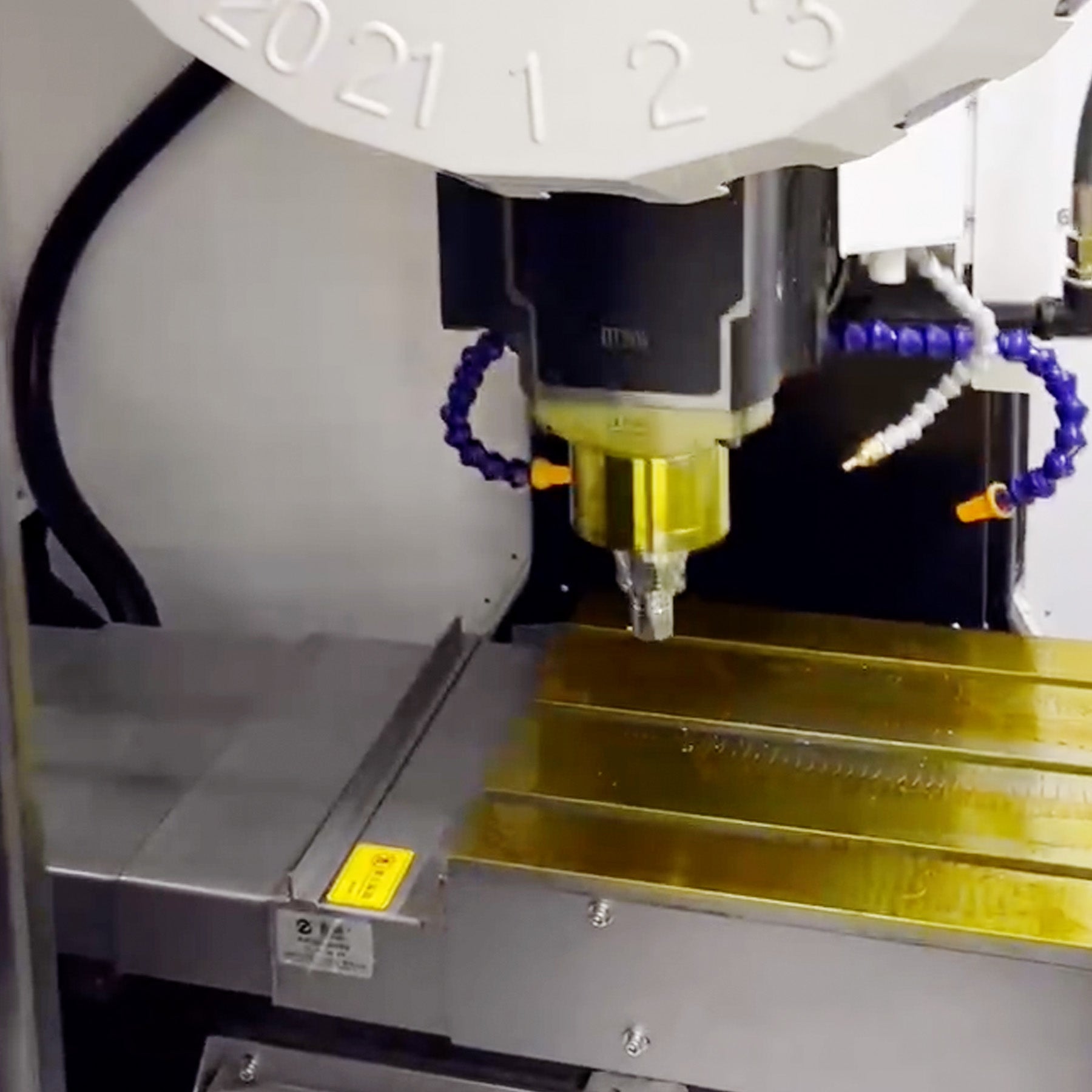

Machine tool in production. Ships later this year.

SYIL T5 Drill Tap Mill

Prices Starting at:

Financing options available.

Enhanced Efficiency and Accuracy

Features

- Axis Travels of 23.62" x 17.72" x 12.99" (600 x 450 x 330 mm)

- 21-pocket High-Speed Servo Tool Changer

- 20,000 rpm Direct BT30 Spindle

- High-Precision Mineral Casting

- THK Ball Screw and Linear Guide

Customization Options

- NC rotary table DDR type | 4th axis 170mm size kits including servo motors and driver | Taiwan Made and DDR type

- NC rotary table Gear type | 4th axis 170mm size kits including servo motors and driver | Taiwan Made and Gear type

- Tailstocks for gear type 4 axis

- Probe System | Wireless type

- Tool Setter Kits | Cable type TTC200

- Filtermist

Country of Origin: Parts sourced from multiple countries. Machine tool assembled in China; packaged and shipped in the USA.

SYIL T5

The SYIL T5 drilling/tapping machine automates your process, and has the effect of increasing your efficiency and productivity while reducing labor costs.

27.56" x 16.54" (700 x 420mm)

3 x 0.56" x 4.92" (3 x 14.3 x 125mm)

551.16 lbs (250kg)

82.60" x 61.02" x 81.50" (2098 x 1550 x 2068mm)

23.62" (600mm)

17.72" (450mm)

12.99" (330mm)

5.91"-18.90" (150-480mm)

12.60" (320mm)

BT30

20,000 rpm

Direct

787.40"/min (20,000mm/min)

1,889.76"/min (48,000mm/min)

Expoxy Granite Frame

Precision mineral bed

THK

High-precision ball screws and linear guides

4th-Axis

Optional 4th-Axis

High-Speed Servo Tool Changer

21 positions BT30

Robert S.

TITANS of CNC delivered a 5-star experience! Titan and Jessie went above and beyond to personally educate me about the SYIL X7. Keith made everything super easy and answered no less than 1,000 of my questions. Their team really cared about my success! All that's left is for me to finalize the machine's placement and see what this thing can do. Can't wait to cut my first chips on this bad boy!

Why Choose the T5 Drill Tap Mill?

Using a drilling and tapping machine offers several advantages in industrial manufacturing. Firstly, it significantly increases efficiency and productivity by automating the process of drilling holes and creating threads. This allows for faster production times and higher output rates, saving valuable time for manufacturers.

Additionally, drilling and tapping machines reduce the labor costs typically associated with manual drilling and tapping processes.

By eliminating the need for constant supervision or physical exertion from workers, companies can allocate their resources more effectively.

Powerful Features

- Powerful and reliable performance

- Compact machine layout, suitable for production line integration

- Mineral-cast bed structure

- High rigidity and good thermal stability

- Direct drive servo motor, high precision guideways

Sleek Design

- Fully enclosed work area with stainless steel protection plates

- Easy chip disposal design

- Ergonomic operation and loading/Unloading design concept

- Easy access to equipment units for easy maintenance

- Expandable and customizable automation system

Automation

Significantly increases efficiency and productivity by automating the process of drilling holes and creating threads. This allows for faster production times and higher output rates, saving valuable time for manufacturers. Additionally, with the ability to accurately drill and tap with precision, this machine ensures consistent results every time.

Save Time and Money

Reduce labor costs associated with manual drilling and tapping processes! By eliminating the need for constant supervision or physical exertion from workers, companies can allocate their resources more effectively. Moreover, using a CNC drill tap machine like the SYIL T5 provides versatility across various applications in industries such as automotive parts manufacturing or aerospace engineering—making it an ideal choice for corporations looking to streamline their operations without compromising quality.

High-Quality and Reliable

When you buy a CNC drilling and tapping machine from SYIL Machine Tools, you can trust that you are getting a high-quality and reliable product. Our machines are built with precision engineering and designed to withstand the demands of industrial manufacturing. You can count on consistent performance and accuracy, ensuring efficient production processes.

Customizable

SYIL Machine Tools offers customizable options for our CNC drilling and tapping machines. We understand that every manufacturer has unique needs, so we provide flexible solutions to meet your specific requirements. From different spindle configurations to advanced control systems, you can customize your machine to optimize productivity and achieve the desired results.

Additional Features

Wheel Type

21 Positions

2.48" (63mm)

9.84" (250mm)

6.61 lbs (3kg)

1s

4.96/7.38 hp (3.7/5.5kW)

2.01 hp (1.5kW)

AC380V/ 3-Phase

82.60" x 61.02" x 81.50" (2098 x 1550 x 2068mm)

4740 lbs (2150kg)

4960 lbs (2250kg)